Bearings play a crucial role in various mechanical systems, enabling smooth and efficient motion between different components as they reduce friction and support loads, ensuring the proper functioning of rotating machinery. When it comes to bearings, two common types are often considered: plain bearings and rolling bearings. In this article, we will explore the characteristics, advantages, and applications of each type, providing you with a comprehensive understanding of their differences.

What are Bearings?

Bearings are mechanical components designed to facilitate smooth movement between two or more parts, such as shafts or axles, within a machine. Bearings enable relative motion while minimizing friction and ensuring proper alignment and are widely used in numerous applications, ranging from automotive engines and industrial machinery to aerospace systems. By providing a smooth interface between moving parts, bearings help to reduce wear and heat generation, leading to improved efficiency and durability.

There are various types of bearings available, each designed for specific applications. In this article, we will focus on two major categories: plain bearings and rolling bearings.

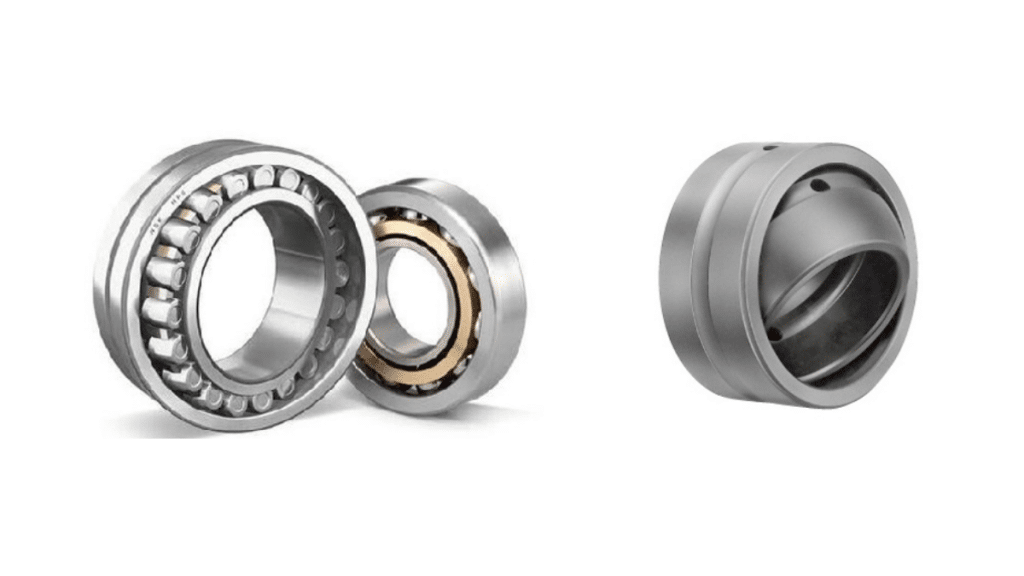

Plain Bearings

Plain bearings, also known as sleeve bearings or bushings, are the simplest type of bearing. They consist of a cylindrical sleeve made of a low-friction material, such as bronze or plastic, which surrounds the shaft or axle. The inner surface of the bearing makes direct contact with the shaft, providing a sliding interface.

Plain bearings function by allowing the shaft to slide smoothly within the bearing surface, reducing friction. The bearing material acts as a lubricant, providing a low-friction interface and minimizing wear. Plain bearings are suitable for applications where low friction and moderate load capacity are required.

Advantages of Plain Bearings

- Cost-effectiveness: Plain bearings are generally more affordable than rolling bearings, making them a popular choice for many applications.

- Simplicity: With their straightforward design, plain bearings are easy to install and maintain.

- High load capacity: Plain bearings can handle heavy loads due to the larger contact area between the bearing and the shaft.

Disadvantages of Plain Bearings

- Friction and wear: Plain bearings have higher friction compared to rolling bearings, which can result in increased energy consumption and wear.

- Lubrication requirements: Most plain bearings require regular lubrication to reduce friction and prevent overheating.

- Noise: Depending on the application and materials used, plain bearings can generate more noise and vibration.

Rolling Bearings

Rolling bearings, also called anti-friction bearings, are more complex in design and offer different advantages compared to plain bearings. They consist of two main components: an inner race, which is attached to the rotating shaft, and an outer race, which houses the rolling elements. The rolling elements, such as balls or rollers, facilitate the smooth rotation of the bearing.

Rolling bearings function by using rolling elements, such as balls or rollers, to reduce friction and support the load. The rolling elements roll between the inner and outer races, minimizing frictional resistance and enabling smooth motion. Rolling bearings are capable of withstanding higher speeds and carrying heavier loads than plain bearings.

Advantages of Rolling Bearings

Rolling bearings offer several advantages, making them suitable for a wide range of applications:

- Low friction: Rolling bearings have lower friction compared to plain bearings, resulting in improved efficiency and reduced energy consumption.

- High-speed capability: Due to their reduced friction, rolling bearings can handle higher rotational speeds.

- Reduced noise and vibration: Rolling bearings tend to generate less noise and vibration during operation.

Disadvantages of Rolling Bearings

- Cost: Rolling bearings are generally more expensive than plain bearings, particularly for high-quality precision bearings.

- Maintenance: Rolling bearings require regular lubrication to ensure optimal performance and prevent premature wear.

- Load capacity: Depending on the specific type and design, rolling bearings may have limitations regarding heavy load capacities.

Plain Bearings Vs. Rolling Bearings

To determine the most suitable type of bearing for a specific application, it’s essential to compare the characteristics of plain bearings and rolling bearings.

Design and Construction

Plain bearings have a simple design, consisting of a cylindrical sleeve and the shaft. They provide a sliding interface between the bearing surface and the shaft. In contrast, rolling bearings have a more complex structure with inner and outer races, rolling elements, and a cage or separator to maintain proper spacing between the rolling elements.

Friction and Efficiency

Plain bearings have higher friction due to the sliding motion between the bearing surface and the shaft. This can result in more heat generation and energy loss. On the other hand, rolling bearings have lower friction since the rolling elements reduce the contact area and allow smoother rotation. This leads to improved efficiency and reduced power consumption.

Load Capacity and Durability

When it comes to load capacity, rolling bearings generally outperform plain bearings. Rolling bearings can handle heavier loads and distribute them more evenly across the rolling elements. They are also more durable and resistant to wear and fatigue, making them suitable for demanding applications.

Speed and Performance

Rolling bearings excel in high-speed applications due to their lower friction and ability to accommodate rotational motion. They are designed to withstand high rotational speeds without compromising performance. Plain bearings, although capable of moderate speeds, may experience higher friction and heat generation at higher velocities.

Lubrication and Maintenance

Plain bearings rely on a lubricating film formed between the shaft and the bearing surface to reduce friction and wear. This requires periodic lubrication to ensure proper functioning. In contrast, rolling bearings typically require less frequent lubrication due to the rolling action of the elements. However, proper lubrication is still essential for their longevity and performance.

Both plain bearings and rolling bearings play significant roles in various mechanical systems, each with its own advantages and applications. Choosing the right type of bearing depends on factors such as load capacity, speed requirements, cost considerations, and maintenance preferences. By understanding the characteristics and differences between plain bearings and rolling bearings, you can make informed decisions to optimize the performance and longevity of your machinery and equipment.

HVH Industrial Solutions offers a wide range of bearings. If you are interested in exploring our extensive range of bearings, please feel free to visit our website at [hvhindustrial.com]. On our website, you will find detailed information about the various types of bearings we offer, their specifications, and their applications.