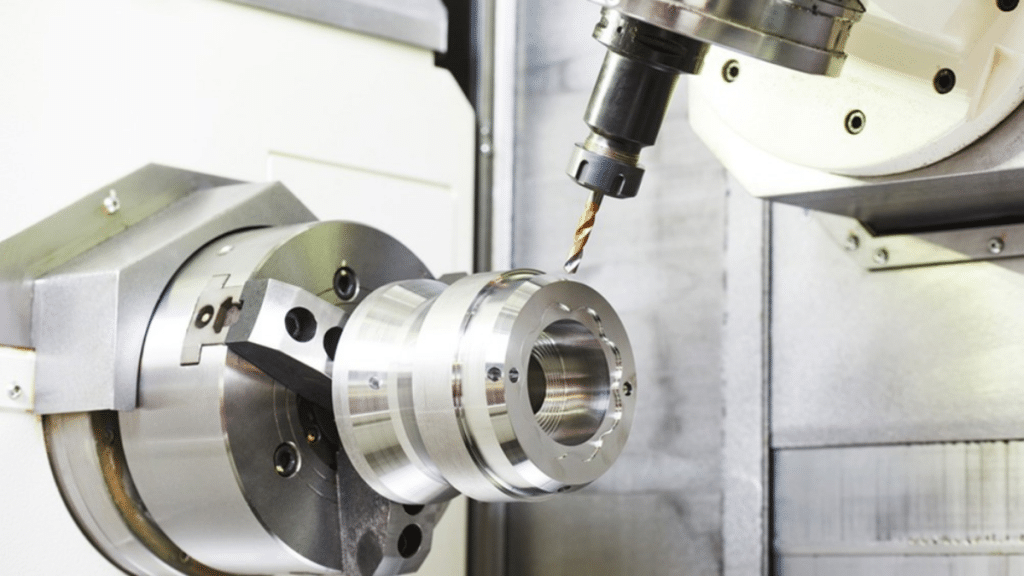

Computer numerical control CNC machining is an accurate process used to make various components, such as automotive and aerospace parts.

CNC machining encompasses processes such as milling, turning, drilling, and plasma cutting. The cost of CNC machining can vary depending on the process implemented and various factors such as material, equipment, and cutting tools.

CNC machined parts manufacturers adopt various methods to minimize machining costs for their consumers without compromising any quality.

This article covers ten effective ways to optimize CNC costs without compromising quality.

1. Improvise Design To Simplify Manufacturing

DFM, or design for manufacturability, is a helpful principle when designing a part or product. Tight corners and undercuts are often a leading factor in rising manufacturing costs because they can increase machining time and demand tools.

Improving these design elements and simplifying complicated shapes can effectively reduce machining time and cost. For example, rounded and larger radi corners are easier to machine than small, tight corners.

DFM is an effective principle that prominent CNC machining companies use to reduce costs and optimize the machining process by reducing steps and processing periods. This can improve turnaround time when prototyping for tight deadlines.

2. Cost-Efficient Material Selection

Different materials have differing properties, such as hardness and machinability. Materials with high hardness, such as titanium, are difficult to machine and require special tools, which can affect the cost of CNC machining.

Selecting a commonly used material such as aluminum or your project results instead of titanium will result in more optimal pricing since harder materials are difficult to process due to increased tool wear and more extended machining periods.

Buying materials in large quantities yields a lower buying rate that can improve cost efficiency, eliminate problems such as market availability, and further improve the process and cost.

3. Minimise preparation time

Installing and setting up equipment is a repetitive process that requires time, increasing the cost of the workpiece since each setup and machine startup has a fixed cost.

A component that requires machining on multiple faces must go through multiple setups and fixturing processes on a 3-axis machine, increasing the cost per piece in low-volume batches.

Combining features and using a 5-axis machine to process your part is a helpful way to reduce your production costs without compromising quality.

Additionally, a high volume production will always result in a more economical rate than a small batch that requires multi-surface machining.

4. Reduce Machining Time

Machining time is the driving factor for CNC costs. Longer operation time means more labour and energy consumption. Computer-aided manufacturing (CAM) is efficient software that reduces cycle time and minimises movements, reducing manufacturing costs.

CAM software can analyse and determine optimal cutting patterns and parameters to reduce the machining time. This is especially useful in large volume production where each stroke can exponentially affect pricing.

Implementing the right technique, cutting speed, and feed rate can simplify the process, reducing time and increasing efficiency, ultimately saving money.

5. Prioritise Automation And Advanced Techniques

An automated machine with limited manual requirements can function continuously to improve machining time and efficiency. This is done by implementing automatic tool changers and handling systems.

Modern machines are AI-powered and integrated with machine learning to determine the best tool path, accounting for tool wear, and improving costs.

The machine can adjust material feed rates and cutting speed in real time to lower energy consumption and labour costs.

Advanced technology is more economical and beneficial in the long run, although it may initially seem costly.

6. Use Standard Tooling and Features

Most materials and tools are cheaper in standardised forms available in the market because custom drills and material sizes are made to demand, which requires special tools to produce.

Using standard tooling, thread types, and materials available can reduce expenses by cutting out any special requirements.

To reduce costs, it is better to avoid thin walls and complex shapes, which demand custom tooling and materials sizes. Personalised features often demand more time and energy in addition to expenses.

Standardised equipment and tools allow manufacturers to reuse equipment and setups to improve costs, making the process economical.

7. Virtual Simulation And Calculations

Modern-day CNC manufacturers use software to simulate the machining process virtually to predict the cost and machining. This simplifies and highlights unnecessary steps in the production to reduce time and cost.

Digital twin technology paired with simulation software reduces waste and mechanical errors in the machining process.

Simulations enable manufacturers to study and improve sustainable practices such as energy-efficient tooling paths, ultimately reducing expenses.

8. Sustainable Practices

Time and energy can be saved by using sustainable practices such as optimized cutting parameters. This helps to lower costs and improve energy consumption and material waste produced during machining.

Sustainable and efficient manufacturers use CNC machines that utilize recyclable coolants and metal scraps to improve production costs and conform to environmental regulations by reducing waste.

9. Relocation Of Manufacturing

Overseas production can have high labor and energy costs, resulting in high manufacturing costs for CNC machined parts.

Relocating your production to domestic facilities or affordable areas can significantly lower machining costs and eliminate variables such as shipping delays. This simplifies the supply chain, which contributes to overall cost reduction.

10. Improve Production Efficiency

A higher volume of production will always result in a lower cost per piece. Setup and fixturing costs remain the same for both scales, but they can be spread across more units in a large-scale production compared to a small batch.

The cost can be reduced by optimized design and reducing production time by using multi-axis tooling and consolidation features.

Conclusion

CNC machining costs can be lowered and made more economical by efficiently implementing CAM and DFM strategies to predict and improve tooling pathways and machining time, which ultimately leads to reducing expenses.

CNC manufacturers are able to improve cost and efficiency by following the above-mentioned methods and strategies to eliminate variables such as logistics and material availability.

This enables manufacturers to excel in a competitive and demanding market.