Filling is a critical step in pharmaceutical packaging, as it determines the amount of medication in one unit. Its importance has called for the top pharmaceutical filling machine. They ensure that medications are dispensed accurately and consistently while minimizing contamination risks and optimizing production throughput.

Then. in 2024, what are the trends in these pharmaceutical filling machines? And what are the basics you should know to navigate this landscape? Which filling machines do you need among types, like pill filling machines? This article will provide a thorough guide; further, you can better understand how to choose the best packaging machinery manufacturer.

Basics about the Pharmaceutical Filling Machine- Types

There are three primary types of pharmaceutical filling equipment based on different drug forms.

1. Liquid Filling Machines

Liquid filling machines, also called liquid fillers, facilitate the accurate dispensing of liquid medications into vials, bottles, or other containers. They can utilize advanced technologies such as piston fillers, peristaltic pumps, or gravity filling systems to deliver precise dosages while minimizing foaming, splashing, or product loss. For your final choice, you may consider the features of the liquid to be handled, including viscosity, foaming ability, and hazardousness.

2. Powder Filling Machines

Powder-filling machines are designed to handle very fine particles, ensuring high-speed filling and dosage accuracy. Their secrets to effectively handling a wide range of powder consistencies lie in their innovative mechanisms, such as auger fillers, vacuum fillers, or vibratory feeders. Additionally, features like dust containment systems and anti-static coatings help maintain cleanliness and prevent cross-contamination.

3. Capsule/Tablet/Pill Filling Machines

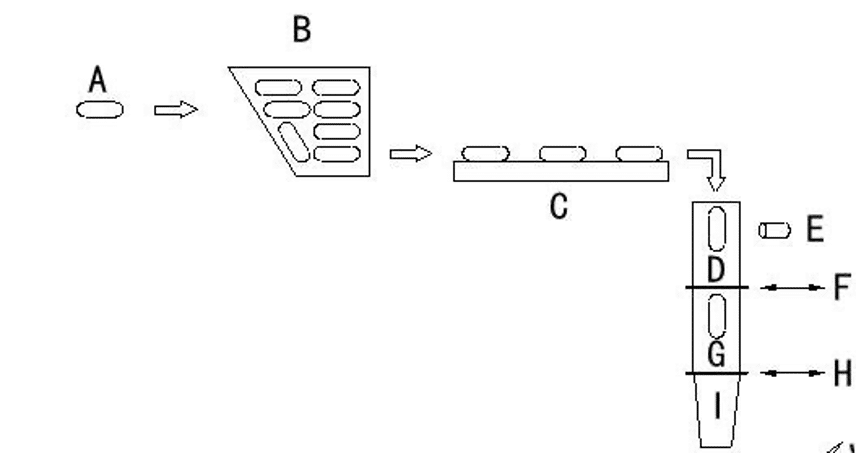

These pharmaceutical filling machines might have the broadest application scope due to the growing demand for solid dosage forms. Usually, they may be referred to as capsule/ tablet/ pill counting and filling machines or simply specific counting machines or counters, as their packaging accuracy relies heavily on precise counting.

They can employ advanced counting mechanisms such as electronic sensors, laser scanners, or weight-based systems to ensure accurate counting and filling of solid medications. Moreover, automation features such as bottle indexing and capping enhance productivity and minimize human error.

What are the Trends for the Pharmaceutical Filling Machine in 2024?

After learning the basic knowledge of different types, we can move on to the new trends for pharmaceutical filling machines. It is expected with the following 4 aspects.

1. Integration of Artificial Intelligence (AI) and Machine Learning

The utilization of AI and machine learning technologies is an unstoppable trend. It will help the pharmaceutical filling equipment to achieve upgraded automation and intelligence levels in aspects like:

- Adaptive Filling: These technologies empower machines to learn from data, respond to changing conditions, and optimize performance in real-time.

- Predictive Maintenance: AI algorithms can analyze vast datasets to identify patterns, predict equipment failures, and optimize filling parameters for maximum efficiency and accuracy.

- Quality Control: Machine learning algorithms can refine dosage delivery based on feedback loops, ensuring precise medication dispensement and minimizing errors. Furthermore, AI-powered vision systems can detect anomalies and contaminants during filling, enhancing product quality and regulatory compliance.

2. Sustainability and Environmental Impact

Another highlighted focus in pharmaceutical packaging will be the shift towards sustainable practices. Be it eco-friendly materials or processes, there is much potential in reducing the environmental footprint of packaging operations.

Regarding pharmaceutical filling machines, the advanced types will come with energy-efficient components and optimized workflows that help minimize resource usage while maintaining productivity.

Some features you can look for are high-efficiency motors, variable frequency control, and modular designs. They help reduce energy consumption or empower flexible production lines to adapt to production needs swiftly, thus reducing equipment idle time and resource wastage.

3. Customization and Flexibility

Modern filling machines in 2024 are also anticipated with greater customization and flexibility due to diverse product portfolios and evolving market demands. For example, those with modular configurations and adaptable features win their edges due to quick changeovers between different packaging formats and product specifications. You can also look for customizable interfaces and software solutions. They help optimize production efficiency and versatility by enabling operators to effortlessly adjust filling parameters and workflows.

4. Remote Monitoring and Maintenance

The last trend for pharmaceutical filling machines we will cover is remote monitoring and maintenance. Advancements, like IoT-enabled sensors & connectivity solutions and cloud-based platforms & predictive analytics tools, will help remotely monitor key parameters and provide actionable insights into equipment health and performance trends.

Moreover, remote diagnostics and troubleshooting functionalities enable prompt and efficient issue resolution, minimizing downtime and maximizing uptime for continuous production operations. Filling equipment that embraces this trend will help you enhance operational efficiency, reduce costs, and ensure uninterrupted supply chains.

Pharmaceutical Packaging Machinery Manufacturer Embracing Trends

After all these discussions, you may have a general overview of the filling equipment you need for your business. Then, what’s the next step to fill in the blank? Yes, you may consult a professional packaging machinery manufacturer who knows all about filling machines and industry innovation.

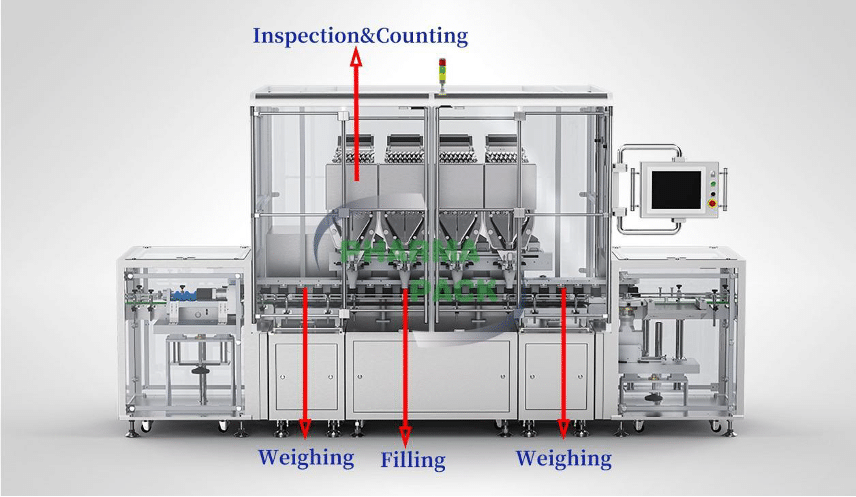

Here, Pharmapack comes with a rather impressive résumé. They master 400+ patented technologies and cutting-edge servo control technology, enabling them to independently develop equipment and software application systems. One of their pioneering packaging solutions is the world’s first counting packaging line with a productivity of 400 bpm, equipped with a track-and-trace system and debris camera detection capabilities.

With 20+ years of evolution, they have established an extensive catalog of pharmaceutical packaging machines. In addition to different pharmaceutical filling machines, they excel in the smart bottle packaging line. For now, they are proactively responding to and harnessing the advantages of IoT technology, striving to develop pharmaceutical packaging solutions with superior capabilities.

Conclusion

As the pharmaceutical industry continues to evolve, packaging machines for this sector are supposed to catch up with the trends for exceptional performance. In this article, we talk about pharmaceutical filling machines and the trends a top one should cater to.

Things can get more detailed when it comes to the specifics. It is highly recommended that you contact Pharmapack, a reliable and professional packaging machinery manufacturer. Drawing upon leading global technology, they are a trusted partner for renowned brands such as Abbott, Baxter, and Pfizer.