Picture a factory floor—all of the thousands of sensors, robotic arms, and control units. A loss of a single packet of data would result in a safety failure.

Office networks differ from industrial networks. Your office network requires high-speed email and web browsing.

What industrial networks require is something more essential: determinism. Information needs to be timely. Lives depend on it. These systems are subjected to extreme temperatures, electromagnetic interference, and constant vibrations. Common hardware would fail instantly. Everything is kept going by reliability, security, and scalability.

This article examines five key components commonly used in industrial environments. These components ensure that modern factories remain efficient and safe.

1. Industrial Ethernet Switches

The Ethernet switch powers each wired industrial network. Industrial switches control the flow of data with precision, ensuring that critical control signals take precedence over less important data.

Industrial switches are robust. They work in challenging environments, such as dusty cement plants and cold storage facilities. Metal casings are shock and vibration-resistant.

Ring Redundancy protocols restore your network in milliseconds in the event of a cable break. They work under extreme temperatures, ranging from -40 °C to +75 °C.

There is a significant shift in market analysis toward managed switches that support Time-Sensitive Networking (TSN). This is a technology that facilitates real-time communication in Industry 4.0.

When upgrading your facility, you need to select the correct industrial switch. It enables your older devices to easily connect with the new IIoT without losing your data.

2. Industrial Gateways and Routers

Whereas switches are used to connect devices within a local network, routers and gateways serve as the bridges that connect the local network to the outside world.

They act as the intermediary between the factory floor and the corporate office (or cloud), bridging the gap between Operational Technology (OT) and Information Technology (IT).

These devices are also becoming increasingly burdened with edge computing, which involves computing the data on-site and then transmitting it to the cloud to minimize latency.

- Remote Access: The secure provision of access to engineers to better diagnose a PLC in Tokyo from a desk in Berlin through VPN.

- Protocol Conversion: Converting old serial data (RS-232) to new IP packets.

5G is becoming a functional requirement of an industrial gateway that could enable the ultra-low latency required with autonomous mobile robots (AMRs).

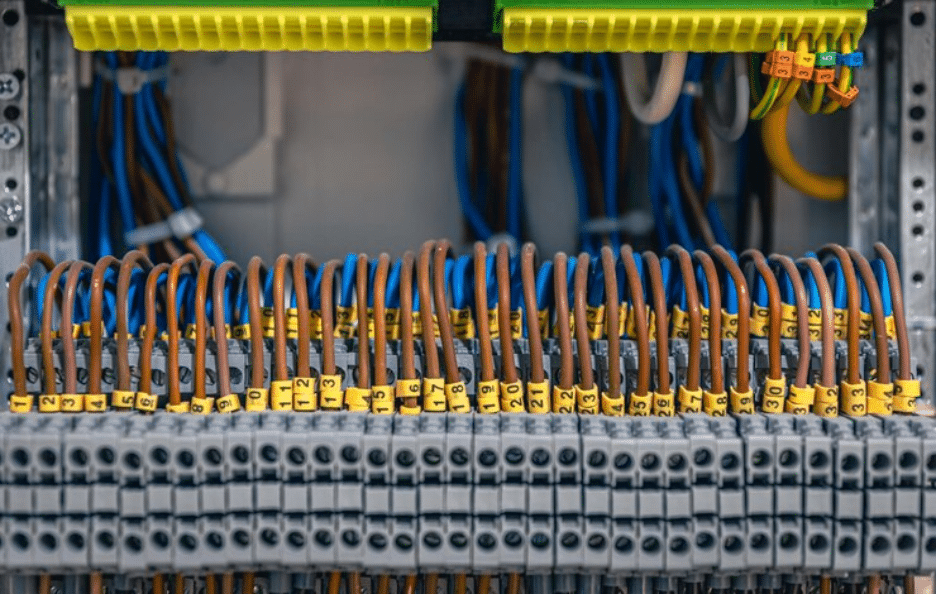

3. Programmable Logic Controllers (PLCs) and Network Interfaces

PLC is the brain of industrial automation. It acquires data through sensors, processes this data according to programmed logic, and transmits instructions to actuators.

PLCs utilize built-in network interface modules to communicate using various industrial protocols and dialects.

- PROFINET & EtherNet/IP: The most common standards of real-time data exchange inside Ethernet.

- Modbus TCP: This is a simple protocol that is reliable and frequently applied to monitor non-critical systems such as temperature gauges.

For example, a PLC used in an automotive assembly line should instruct a robotic arm to weld a chassis at the precise point where the conveyor belt places it.

Any slight delay created by the network interface would cause misalignment of the weld, which would lead to a flawed product.

4. Industrial Wireless Access Points

Gone are the days when all was wired. Industrial wireless access points (WAPs) are opening up new horizons of movement and freedom, allowing assets such as forklifts and handheld scanners to remain connected as they move across a facility.

Wireless technology can be used to monitor rotating equipment, such as turbines, where it is impractical to run a physical cable. The factory floor, however, is not a suitable environment for radio waves due to the presence of metal structures that act as Faraday cages.

Challenges and Solutions

- Mitigation of Interference: In current industrial WAPs, advanced technologies such as beamforming are employed to target the device with the signal, thereby reducing the electronic noise generated by variable frequency drives (VFDs).

- Wi-Fi 6/6E Adoption: The primary driver behind Wi-Fi 6 is its capacity to support hundreds of simultaneous connections, which is essential in warehouses with large numbers of IoT sensors.

5. Network Security and Monitoring Devices

As OT and IT converge, the physical isolation of air-gapped protection, which was prevalent in the past (where industrial networks were not physically connected to the internet), is virtually nonexistent. This connectedness is efficient, yet cyber threats are introduced.

Physical safety is a subject of security in industrial settings. An infiltrated cooling system may cause a chemical blast.

- Industrial Firewalls: DNP3 or BACnet-aware networks. Special types of firewalls can recognize industrial protocols (such as DNP3 or BACnet) and filter out malicious commands, while allowing legitimate read requests to pass through.

- Intrusion Detection Systems (IDS): These are passive listeners that inspect network traffic for abnormalities, such as a PLC being reprogrammed at 2 AM.

Zero-trust architectures are gaining attention in OT environments. AI is now being integrated into tools to predict threats before they are executed.

For example, when a water treatment pump typically receives 50 commands per hour, an AI sensor will detect an immediate surge in 5,000 commands as a potential Denial-of-Service (DoS) attack.

Conclusion

To have a powerful industrial network, you must possess the appropriate special elements. Every part counts, including everything from rugged Industrial Ethernet switches to intelligent security equipment.

Now we are witnessing the real changes. 5G, AI surveillance, and improved wireless standards are changing factory floors. Knowing these five vital elements will equip you for your future activities.