The explosive growth of online shopping and global supply chains has reshaped the logistics industry. As customer expectations shift toward same-day or next-day delivery, businesses must adapt by improving operational efficiency—especially in package sorting. A slow or error-prone parcel sorting system can become a major bottleneck, leading to delivery delays, lost packages, and customer churn.

Whether you’re running a small warehouse or managing a large logistics hub, investing in the right parcel sorter can streamline workflows, reduce labor costs, and scale your capabilities. But which system fits your business best? Below, we explore seven common parcel sorting systems in depth.

Option 1: Manual Sorting Systems

Manual parcel sorting is the most basic method, involving human workers physically sorting packages by hand or using basic tools like carts, totes, and sorting bins. While it lacks technological sophistication, it offers flexibility and simplicity for small operations.

Advatages:

- Low Capital Requirement: Initial investment is minimal, often limited to racking, labels, and manual labor. For businesses with uncertain or fluctuating volumes, this makes manual sorting appealing.

- Adaptability: Workers can quickly adapt to unique packages or unusual sorting scenarios, which automated systems may struggle with.

- Training Time: Onboarding staff for manual sorting is quicker and doesn’t require technical expertise.

Limitations:

- Error Rate: Fatigue and repetitive tasks increase human error, especially during peak seasons.

- Labor Costs: As volume grows, labor costs scale linearly. More orders mean more workers, which is not sustainable long-term.

- Throughput Ceiling: There’s a hard limit to how fast humans can sort, which restricts scalability.

Use Case: Startups, local couriers, or warehouses handling fewer than 500 parcels per day.

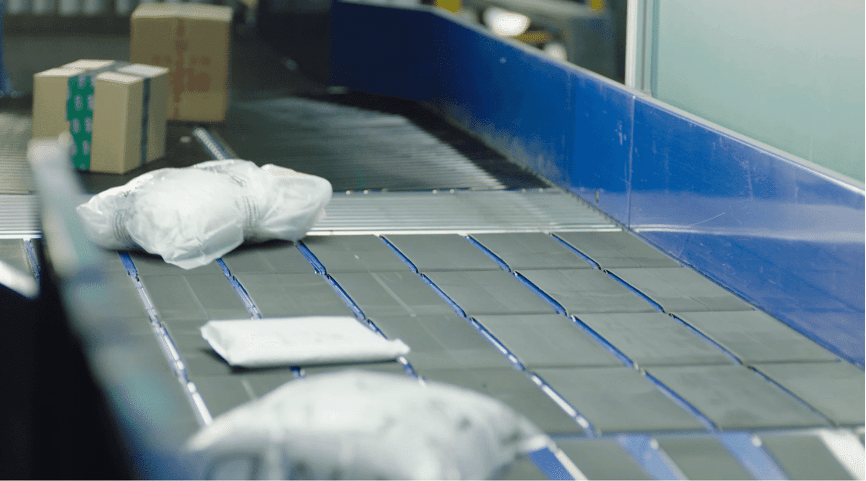

Option 2: Conveyor Belt Sorting

Conveyor belt systems are a mechanical method of transporting packages across different zones in a warehouse. They often work in conjunction with barcode scanners and manual scanning stations.

Advantages:

- Efficiency Boost: Conveyors can move hundreds or thousands of packages per hour, reducing the need for manual transportation.

- Reduced Travel Time: Workers spend less time walking and more time doing value-added tasks, improving overall productivity.

- Custom Configurations: Systems can be tailored to route packages based on destination, weight, size, or shipping method.

Challenges:

- High Upfront Cost: Installing conveyors with smart routing can cost hundreds of thousands of dollars depending on length and complexity.

- Inflexibility: Once installed, rerouting conveyors or redesigning the layout is costly and time-consuming.

- Maintenance Dependency: Downtime due to motor failures or misalignment can halt the entire process.

Use Case: Medium-sized fulfillment centers shipping between 1,000–10,000 parcels per day, where automation is needed but full robotics may be excessive.

Option 3: Tilt Tray Sorter

Tilt tray sorters use trays that carry parcels and gently tilt to discharge items into designated chutes or bins. They’re known for reliability and speed in high-volume operations.

Advantages:

- Consistent High Throughput: Capable of processing up to 20,000 items per hour, making it ideal for enterprise-level logistics.

- Parcel Versatility: Can handle irregular shapes, soft packages, and hard goods with minimal issues.

- Integration Friendly: Often combined with scanning systems and WMS (Warehouse Management Software) for real-time parcel tracking.

Challenges:

- Space-Intensive: These systems require a large footprint and ceiling height, limiting their suitability for smaller facilities.

- Complex Maintenance: The mechanical components, sensors, and trays need routine inspection and cleaning to avoid jams or mis-sorts.

- Implementation Time: Full deployment can take months from design to go-live.

Use Case: National distribution hubs, third-party logistics providers (3PLs), or enterprises with high daily parcel volumes and standardized packaging.

Option 4: Cross-Belt Sorter

The cross-belt sorter uses motorized belts mounted perpendicular to a main conveyor line. It allows for independent movement and precise discharge of each package into bins or chutes.

Advantages:

- Exceptional Accuracy: Designed for high-precision sorting of small or fragile items, often with error rates under 0.01%.

- Compact and Modular: Offers a tighter layout than tilt tray systems, ideal for operations with limited space but high volume.

- Ideal for E-commerce: Handles thousands of SKUs efficiently, making it a favorite for online retailers.

Challenges:

- Cost Barrier: Advanced automation and software integration come with a high price tag.

- System Complexity: Requires skilled operators and a robust IT backbone for integration with inventory and shipping systems.

- Maintenance Downtime: Sophisticated mechanics mean more potential failure points if not managed properly.

Use Case: E-commerce fulfillment centers, fashion warehouses, or electronics distributors needing accuracy and speed.

Option 5: Automated Guided Vehicles (AGVs)

AGVs are mobile robots that navigate warehouse floors, transporting packages autonomously. Their intelligence comes from sensors, maps, and software systems that allow them to avoid obstacles and follow optimized routes.

Advantages:

- Modular and Scalable: You can start with a few AGVs and add more as volume increases. No need for full facility reconfiguration.

- Flexible Layouts: Unlike fixed conveyors, AGVs adapt to changing layouts and can be redeployed to new workflows quickly.

- 24/7 Operation: AGVs can work overnight, recharge themselves, and reduce the need for round-the-clock staff.

Challenges:

- Navigation Accuracy: Environments with poor lighting or reflective floors can affect AGV sensors.

- Traffic Management: In high-density environments, AGVs can cause bottlenecks if routing is not optimized.

- Software Costs: Requires investment in fleet management systems and wireless communication infrastructure.

Use Case: Growing warehouses that want to test automation or facilities that frequently change their layout.

Option 6: Robotic Arm Sorting

Robotic arms with computer vision and AI capabilities are transforming package sorting by mimicking human dexterity and judgment.

Advantages:

- Handles Complex Items: Can sort items of varying sizes, weights, and shapes, even when mixed together.

- Vision Recognition: Uses image processing to identify barcodes, labels, or package type—ideal for operations with poor labeling consistency.

- Labor Substitution: One robotic arm can replace several workers in repetitive sorting tasks, especially in environments with high labor costs.

Challenges:

- High Investment in AI & Sensors: Needs robust vision systems and machine learning algorithms.

- Not Ideal for Heavy Parcels: Most arms have limited payloads, typically under 10kg.

- Requires Clean, Stable Environment: Dust, debris, or inconsistent lighting can interfere with sensors and cameras.

Use Case: High-tech warehouses and sorting centers with a focus on automation, especially where labor availability is limited or inconsistent.

Option 7: Hybrid Sorting Systems

Hybrid parcel sorting systems combine multiple automation technologies—such as cross-belt sorters, AGVs, robotic arms, and conveyors—into one unified, intelligent solution. Unlike traditional systems built around a single mechanism, hybrid systems offer a modular and adaptive approach to complex sorting needs.

Advantages:

- Tailored Workflows: Different parcel types can be routed through specialized subsystems—for example, small e-commerce items through robotic sorters, and heavier packages via tilt tray lines.

- System Coordination: Central software orchestrates all components, directing parcels in real time based on volume, urgency, or operational status.

- Scalable and Future-Proof: New technologies can be integrated over time, making hybrid systems ideal for businesses anticipating growth or change.

Challenges:

- Integration Complexity: Combining diverse equipment and software requires careful planning and technical expertise.

- Higher Setup Cost: Initial investment is greater, though long-term ROI can be significant.

- Operational Demands: Running a hybrid system requires teams skilled in both automation and data systems.

Use Case: Large-scale logistics hubs or fast-growing businesses needing flexibility, speed, and the ability to handle diverse parcel profiles across multiple workflows.

How to Choose the Right Parcel Sorting System?

To choose the right package sorter, businesses should analyze:

- Volume & Growth Forecast: Current daily volume and projected growth over the next 3–5 years.

- Budget Allocation: Don’t just factor in capital costs—consider maintenance, training, and software.

- Technical Readiness: Evaluate your IT infrastructure and staff readiness to support automation.

- Facility Layout: Some systems need significant space and ceiling height; others are more compact.

Siwun’s Intelligent Sorting System

Siwun’s intelligent parcel sorting system combines AI, robotics, and modular hardware to deliver cutting-edge performance for modern warehouses. With real-time decision-making, predictive maintenance alerts, and seamless integration with WMS/ERP systems, Siwun empowers businesses to sort faster, smarter, and with fewer errors.

Whether you need to optimize existing flows or fully transform your package sorting capabilities, Siwun offers the flexibility and technology edge to help you stay ahead.

Conclusion

There’s no one-size-fits-all parcel sorting system. Each technology has its strengths, costs, and ideal use case. As logistics becomes more complex, the smartest move is to match your sorting solution with your operational strategy.

From manual systems to AI-driven robots, the future of package sorting is both exciting and essential. Make your investment count by choosing the right system for today—and tomorrow.