When it comes to ensuring reliable power supply, diesel generator sets (DG sets) play a critical role across industries. Whether you’re in construction, manufacturing, or energy, understanding how these machines work and how to maintain them efficiently can make a significant difference in performance and longevity. Below are 10 essential facts about diesel generator sets that every industry professional should know.

1. Impact of Different Climatic Environments on Diesel Generator Set Operation

Various climatic conditions can affect the operation of diesel generator sets. For example, rain, dust, and sand can damage machine components, while saltwater and mist from coastal areas can accelerate corrosion of metal parts. Additionally, corrosive gases in the air, such as sulfur dioxide, can harm internal components of the generator set.

2. Components of Diesel Generator Sets

A complete diesel generator set primarily consists of three parts: the diesel engine, generator, and controller. In addition, other components include the base, base fuel tank, radiator, water tank, anti-vibration pads, soundproof box, muffler, and silent box, all of which work together to ensure the proper functioning and environmental adaptability of the generator set.

3. Noise Level Introduction

The impact of noise on human health cannot be ignored. An ideal quiet environment should have a noise level of 30-40 decibels. When the noise exceeds 50 decibels, it can affect sleep and rest; over 70 decibels will interfere with normal conversations and reduce work efficiency. Prolonged exposure to noise levels above 90 decibels may lead to hearing impairment, nervous exhaustion, headaches, and increased blood pressure. A sudden exposure to noise levels as high as 150 decibels can cause severe damage to hearing organs, such as ruptured eardrums and complete hearing loss. Therefore, it is recommended to control noise levels as follows:

- 90 decibels: Protect hearing

- 70 decibels: Ensure normal work and study

- 50 decibels: Ensure quality rest and sleep

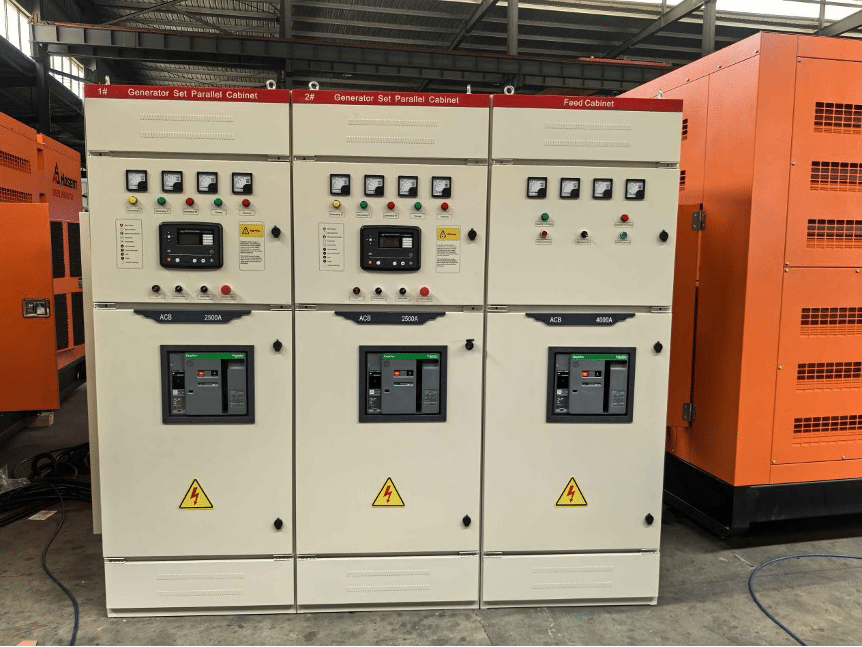

4. Purpose of Parallel Operation of Diesel Generator Sets

Parallel operation allows for increased power capacity, enhances supply reliability, and ensures uninterrupted power supply, especially when there is a high load demand. Running multiple generator sets in parallel can provide more stable and efficient power.

5. Fuel Consumption Calculation

Fuel consumption (L/h) can be calculated using the following formula:

Fuel Consumption (L/h)=Rated Power of Diesel Engine (kW)×Fuel Consumption Rate (g/kWh)/ 1000×0.84

Where the density of diesel is 0.84kg/L.

6. Consequences of Long-Term Overload on Diesel Generator Sets

While diesel generator sets can tolerate short-term overloads, prolonged overloading can cause adverse effects. Overloading may lead to overheating of the cooling system, overheating of the generator windings, breakdown of lubricating oil causing low oil pressure, and reduced lifespan of the generator set. Therefore, it is essential to avoid running the generator under excessive load for extended periods.

7. Cooling System of Diesel Generator Sets

The cooling system of a diesel generator set is crucial to its proper operation. There are two main types: water cooling and air cooling. Water cooling systems circulate water to absorb heat from the engine, suitable for high-power units; air cooling systems use fans to dissipate heat, suitable for smaller units. In hot environments, maintaining the cooling system is essential, as overheating can damage critical components.

8. Maintenance Cycle of Diesel Generator Sets

Regular maintenance is vital for the long-term stability and performance of diesel generator sets. Common maintenance tasks include changing engine oil, checking the coolant, cleaning the fuel system, and replacing air filters. Typically, routine maintenance should be done every 250-500 hours of operation, with adjustments based on the manufacturer’s guidelines. Regular servicing significantly extends the lifespan of the generator set and ensures its efficiency.

9. Emission Control of Diesel Generator Sets

With increasingly strict environmental regulations, emission control has become a key focus for diesel generator sets. To reduce environmental impact, modern diesel generator sets are equipped with advanced emission control systems, such as catalysts and particulate matter filters. Ensuring the generator set’s emissions comply with relevant standards not only helps reduce pollution but also prevents legal penalties.

10. Automation Control System of Diesel Generator Sets

Modern diesel generator sets rely heavily on automation control systems to achieve remote monitoring and automatic start/stop. These systems improve operational efficiency and can trigger alerts if the generator experiences a malfunction, automatically switching to a backup unit to ensure continuous power supply. The automation system can also provide real-time monitoring of the generator’s operational status, allowing users to track its health at all times.

Why Understanding Diesel Generator Sets Is Crucial for Your Operations

Whether you’re looking to reduce downtime, optimize fuel efficiency, or ensure compliance with environmental standards, a clear understanding of diesel generator sets is vital. Proper maintenance, the right setup, and an awareness of the environmental impact can significantly affect your bottom line.

If you’re looking for reliable and high-performance Chinese diesel generator, consider exploring options that meet the specific needs of your industry. With over 20 years of experience in manufacturing high-quality diesel generators, we are committed to providing power solutions that keep your operations running smoothly.