The L5P Delete Kit has become a focal point in automotive performance discussions, particularly for owners of vehicles equipped with GM’s L5P Duramax diesel engines. This modification suite, designed to bypass or remove factory-installed emissions control systems, offers both technical advantages and significant considerations. Below, we explore its core benefits, operational implications, and critical factors users must evaluate before implementation.

Understanding the L5P Delete Kit

The L5P Delete Kit targets emissions-related components in diesel engines, such as the Diesel Particulate Filter (DPF), Exhaust Gas Recirculation (EGR) system, and Selective Catalytic Reduction (SCR). These systems, mandated by environmental regulations, often restrict engine performance and fuel efficiency. By removing or reprogramming these components, the kit aims to restore the engine’s inherent capabilities while addressing common reliability issues associated with emissions hardware.

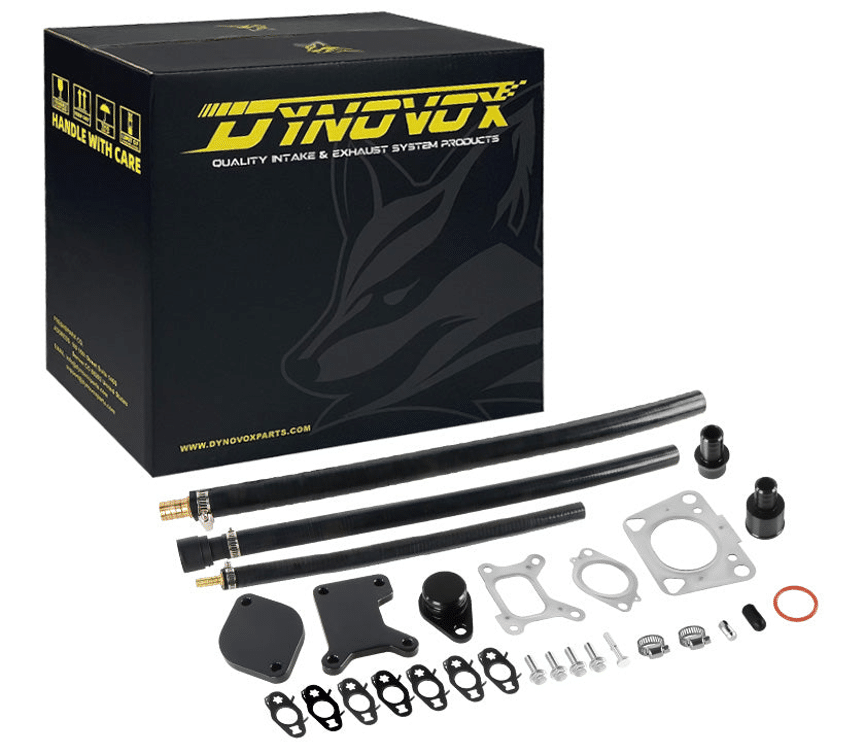

DynoVox’s L5P Delete Kit provides an ideal solution for those looking to optimize their L5P Duramax engine. Known for precision and performance, DynoVox’s kit eliminates factory restrictions, enabling significant power gains and improved fuel efficiency.

Key Benefits of the L5P Delete Kit

1. Enhanced Engine Performance

Factory emissions systems impose limitations on airflow, fuel mapping, and exhaust flow to meet regulatory standards. The L5P Delete Kit eliminates these constraints, enabling optimized combustion and turbocharger efficiency. Users often report noticeable improvements in horsepower (up to 20–30% gains) and torque, particularly in towing and high-load scenarios.

2. Improved Fuel Economy

Emissions control systems, especially DPFs, force engines into frequent regeneration cycles to burn off accumulated soot. These cycles consume additional fuel and reduce mileage. Deleting these systems can improve fuel efficiency by 10–15%, depending on driving conditions.

3. Reduced Maintenance Costs

Emissions components are prone to failure. For instance, DPF replacements can cost upwards of $3,000, while EGR valve malfunctions often lead to coolant contamination. By removing these parts, users avoid costly repairs and extend the engine’s service life.

4. Elimination of Regeneration Cycles

DPF regeneration cycles not only waste fuel but also introduce heat stress to the engine. The delete kit prevents these cycles, reducing thermal wear on critical components like pistons and cylinder heads.

5. Customizable Tuning Options

Modern delete kits integrate with engine control units (ECUs) to recalibrate parameters such as injection timing and boost pressure. Advanced users can fine-tune these settings to align with specific performance goals, leveraging tools akin to firmware-mod-kit utilities for granular control.

DynoVox offers a comprehensive performance upgrade solution for 2017–2023 6.6L Duramax engines with its L5P Delete Kit series. The L5P EGR Valve & Cooler Delete Kit eliminates problematic EGR components, preventing carbon buildup and coolant contamination while improving engine longevity. For enhanced exhaust flow and power gains, the 5″ Downpipe Back Delete Race Pipe features a high-diameter design with mandrel-bent tubing, optimized for reduced backpressure and turbo responsiveness. Additionally, the DPF Delete Pipe removes restrictive diesel particulate filters, eliminating regeneration cycles and improving fuel efficiency. Engineered with precision-fit OEM-grade materials, this trio ensures compatibility with Sierra/Silverado L5P platforms, delivering optimized airflow, reduced maintenance, and sustained performance for off-road or racing applications.

Considerations Before Deleting an L5P Duramax

Legal and Compliance Factors

In many regions, modifying or removing emissions systems is illegal for on-road use. While delete kits offer numerous benefits, they are intended for off-road or competition use only. Truck owners should check local emissions regulations to ensure compliance before proceeding.

Warranty Considerations

Removing emissions components can void the manufacturer’s warranty, making it a crucial factor to consider before performing a delete. To minimize potential risks, truck owners may choose to wait until the factory warranty has expired before making any modifications.

Proper Tuning is Essential

A custom ECU tune is necessary to ensure the truck operates correctly after emissions components are removed. Professional tuning software plays a key role in optimizing fuel injection, boost levels, and sensor settings. Proper tuning helps prevent check engine lights or diagnostic trouble codes from appearing while also improving fuel economy for more consistent performance.

L5P Delete Kit Installation Procedure

1. Preparation & Safety

Disconnect the vehicle battery to prevent electrical hazards.

Gather tools: torque wrench, socket set, exhaust removal tools, and ECU programming interface.

2. Removal of OEM Components

a. Exhaust System Dismantling

Detach the diesel particulate filter (DPF) and selective catalytic reduction (SCR) assembly using appropriate lifting equipment.

Carefully remove exhaust sensors and wiring harnesses to avoid damage.

b. EGR System Removal

Unbolt the exhaust gas recirculation (EGR) valve and cooler.

Seal open ports with heat-resistant caps to prevent debris ingress.

3. Installation of Delete Kit Components

a. Hardware Integration

Install the provided straight-pipe exhaust system, ensuring proper alignment and torque specifications.

Replace the EGR system with block-off plates, applying high-temperature sealant for gaskets.

b. Sensor & Wiring Adjustments

Bypass or reprogram oxygen/NOx sensors using kit-specific adapters.

Secure all electrical connections with waterproof loom tubing.

4. ECU Software Configuration

Connect a compatible tuning tool (e.g., EFI Live or HPTuners) to the OBD-II port.

Upload the preconfigured delete tune file to disable emission-related fault codes.

Validate the calibration by checking for active diagnostic trouble codes (DTCs).

5. Post-Installation Verification

Reconnect the battery and perform a system reboot.

Conduct a road test to monitor engine parameters (boost pressure, exhaust temps) using diagnostic software.

Inspect for exhaust leaks or mechanical interference points.

Maintenance Recommendations: Schedule periodic inspections of turbocharger and exhaust joints, as removal of emission systems may alter backpressure dynamics.

Alternative Solutions to L5P Delete Kit

While the L5P Delete Kit traditionally involves removing or bypassing the L5P engine’s emissions components, several alternative approaches exist for compliance and performance optimization without full deletion. Below are the primary alternatives:

1. ECU Reprogramming

Optimize engine performance through Electronic Control Unit (ECU) remapping. This method adjusts fuel injection timing, turbo boost pressure, and emissions parameters to enhance efficiency while retaining factory hardware. Reprogramming ensures compliance with emission standards and avoids legal risks associated with deletion.

2. Aftermarket Emissions Control Systems

Install upgraded emissions components, such as high-efficiency Diesel Particulate Filters (DPF) or Selective Catalytic Reduction (SCR) systems. These solutions reduce particulate matter and NOx emissions without requiring hardware removal, aligning with regulatory requirements.

3. Maintenance and Component Upgrades

Regular maintenance (e.g., DPF cleaning, EGR valve inspections) and replacing worn parts can restore engine performance. For instance, upgrading to corrosion-resistant EGR coolers or reinforced turbochargers extends component lifespan and reduces failure risks.

4. Hybrid Software-Hardware Solutions

Use diagnostic tools to reset fault codes and implement partial software overrides. For example, disable specific sensor alerts while retaining critical emissions functions. This balances performance gains with minimal system alteration.

Conclusion

The L5P Delete Kit represents a technical solution for users prioritizing mechanical integrity and performance over emissions compliance. When implemented correctly with professional-grade components and tuning, it transforms the L5P Duramax into a more durable and responsive powerplant. However, users must carefully weigh legal responsibilities and environmental considerations against the documented performance advantages.

For those seeking a reliable and efficient solution, the DynoVox L5P Delete Kit stands out as a top-tier choice. Engineered to optimize engine performance, this kit enhances horsepower and fuel efficiency while addressing emission-related restrictions common in stock configurations. Its precision-crafted components ensure seamless compatibility with L5P systems, and the installation process is streamlined for both professionals and DIY enthusiasts. Backed by rigorous testing and industry certifications, DynoVox offers a robust warranty and technical support, prioritizing long-term reliability.