Co-extrusion refers to a process in which multiple plastic materials are pushed together from separate extruders to form a multi-layered product.

Each material retains its position due to differing viscosities, preventing them from mixing. This allows different properties to be combined (such as strength and flexibility) in a single product, making it functional and suitable for complex applications.

Difference between extrusion and co-extrusion

Extrusion and co extrusion are processes that are often confused, but each has its own unique features. In the first case, solid plastic pellets are gravity-fed into a forming mechanism, where compression screws melt the material. The molten plastic is then pushed through a die to create a continuous shape, typical of single-material products such as tubes, pipes, and sheets.

Co-extrusion, on the other hand, uses multiple extruders operating simultaneously with different materials, as previously mentioned. These materials are combined in a die to form a single multilayer product.

However, the process itself isn’t the only difference—other key distinctions include:

- Type of material used: traditional extrusion uses a single type of plastic material, typically in the form of uniform pellets. This makes the process simpler, with direct control over the final product’s properties—ideal for items that don’t require complex features. In contrast, co-extrusion simultaneously employs multiple materials (different types of polymers, functional adhesives, or barrier layers). This technology allows for the combination of physical and chemical properties from different materials into a single product, offering more advanced and high-performance solutions;

- Applications: extrusion is widely used in the production of uniform plastic items such as pipes, rigid profiles, sheets, and technical components where a single material composition is sufficient. Co-extrusion, however, is more suitable for contexts that require multifunctional products. Common examples include multilayer food packaging, which provides barriers to gas and moisture, medical tubing with special coatings, and automotive components that require differing properties between the surface and the core;

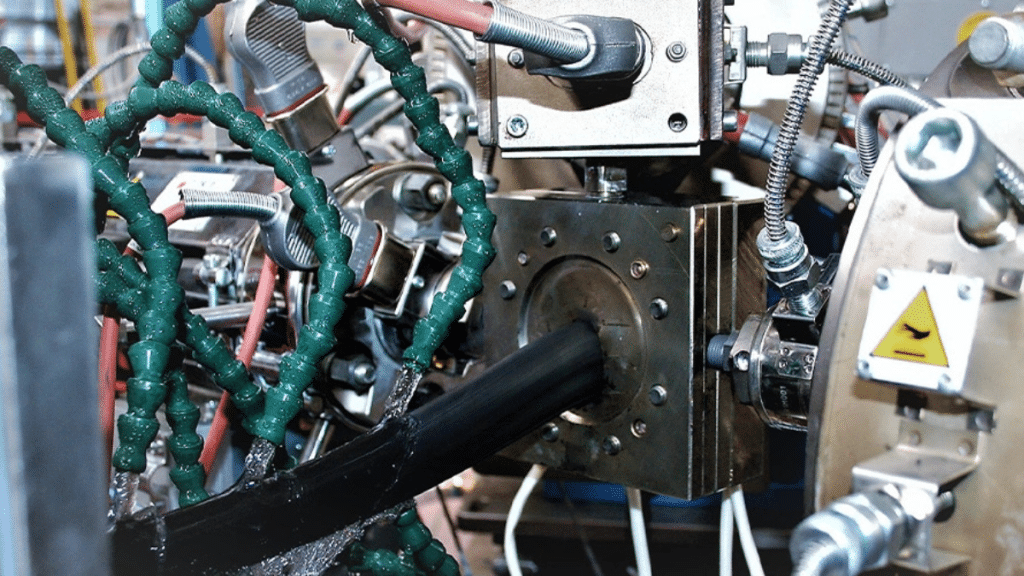

- Equipment and configuration: a standard extrusion line typically requires just one extruder, a die that defines the product’s shape, and a cooling system. The setup is relatively simple, easily scalable, and suitable for continuous high-volume production. Co-extrusion, on the other hand, involves multiple extruders—each dedicated to a different material—coordinated to feed a specialized die capable of combining the layers. This also requires advanced control systems to regulate temperatures, flow rates, and adhesion between the materials;

- Final quality and performance: products made through extrusion are generally uniform, but their quality is closely tied to the characteristics of the single material used. Co-extrusion, in contrast, enables the creation of items with customized properties, such as enhanced mechanical strength, flexibility, selective transparency, or insulation. The ability to integrate multiple functions into a single product makes co-extrusion a strategic choice for technical applications and industries that demand high and specific performance.

Why choose co-extrusion

Co-extrusion is a process that offers numerous advantages. For example, it allows different properties—such as strength and protection—to be combined, enhancing the overall quality of the final product. Additionally, by strategically distributing materials, more affordable ones can be used in the inner layers, while premium materials are reserved for the outer layers of finished products. This results in significant cost savings.

Co-extrusion also makes it possible to produce items with variable rigidity, making them adaptable to different requirements and a wide range of industrial sectors. This process is efficient, flexible, and enables the creation of durable components with high performance and precise control over technical specifications.