What Is CNC Turning?

CNC turning is a machining process that uses computer numerical control to create parts from metal or other materials. It offers many benefits over traditional machining processes, including improved accuracy and greater flexibility. Additionally, CNC turning can be used to create a wide variety of parts, making it a versatile manufacturing option.

How Does CNC Turning Work?

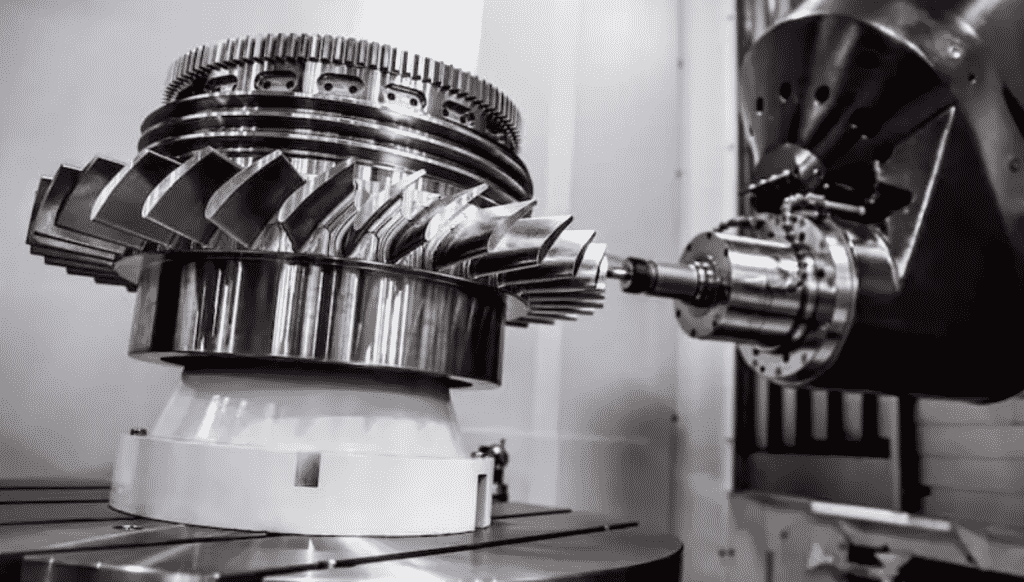

CNC turning works by rotating a workpiece while a cutting tool is applied to it. The cutting tool is controlled by a computer, which allows for very precise cuts. This machining process can be used to create parts from a variety of materials, including metals, plastics, and composites.

What Materials Can Be Used With It?

CNC turning can be used to create parts from a variety of materials, including metals, plastics, and composites. It is particularly well-suited for creating metal parts, as it offers superior accuracy and flexibility when compared to traditional machining processes.

Key Benefits

There are many benefits to using CNC turning, including:

Improved accuracy: CNC turning offers improved accuracy over traditional machining processes. This is due to the fact that the cutting tool is controlled by a computer, which allows for very precise cuts.

Greater flexibility: CNC turning can be used to create a wide variety of parts, making it a versatile manufacturing option. This flexibility can be particularly useful for businesses that need to create a variety of parts quickly and efficiently.

Reduced setup time: Unlike traditional machining processes, which require extensive setup time, CNC turning can be up and running very quickly. This can be particularly beneficial for businesses that need to produce a large number of parts in a short amount of time.

What Industries Commonly Use CNC Turning?

CNC turning is commonly used in industries such as aerospace, automotive, and medical. This is due to the fact that it offers superior accuracy and flexibility when compared to traditional machining processes. Additionally, CNC turning can be used to create a wide variety of parts, making it a versatile manufacturing option.

If you’re looking for a reliable, flexible machining process that can produce a wide variety of parts, CNC turning may be the best option for you. Contact a machining specialist to learn more about this process and how it can benefit your business.

What Are Some Products That are Produced Using This Technology?

Some of the products that can be produced using CNC turning include:

-Aerospace parts

-Automotive parts

-Medical devices

-Dental implants

-Artificial limbs

How Does CNC Turning Compare to Other Types of Machining?

CNC turning offers many benefits over traditional machining processes, including improved accuracy and greater flexibility. Additionally, CNC turning can be used to create a wide variety of parts, making it a versatile manufacturing option.

How Can You Ensure You Get the Best Value for Your Money?

When looking for a machining process that offers the best value for your money, it is important to consider both accuracy and flexibility. CNC turning offers both of these benefits, making it a good option for businesses that need to create a variety of parts quickly and efficiently. Additionally, CNC turning can be used to create parts from a variety of materials, making it a versatile manufacturing option.

How Do You Set Up a CNC Turning Machine?

First, select the appropriate CNC machine for the job. There are a variety of machines available on the market, so it is important to select one that is well-suited for the task at hand. Next, the cutting tool must be selected and installed. Once the tool is in place, the workpiece can be set up and the machining process can begin. Finally, the finished part can be removed and inspected.

What Kind of Maintenance Is Required to Keep it Running Smoothly?

CNC turning machines require very little maintenance. However, it is important to keep the cutting tools sharp and in good condition. The machine should be kept clean and free of debris to ensure optimal performance. Additionally, the machine should be regularly calibrated to ensure accuracy.

What Safety Precautions Should Be Taken When Using This Technology?

When using any type of machinery, it is important to take proper safety precautions. CNC turning machines are no exception. Some of the safety precautions that should be taken when using this technology include:

-Wearing proper Personal Protective Equipment (PPE)

-Making sure the work area is clean and free of debris

-Ensuring that all safety guards are in place and functioning properly

-Never touching the moving parts of the machine

-Being aware of the hazards associated with machining processes

Conclusion

CNC turning is a versatile, accurate, and flexible manufacturing process that can be used to create a wide variety of parts. This technology offers many benefits over traditional machining processes, making it a good option for businesses that need to produce high-quality parts quickly and efficiently. Contact a machining specialist to learn more about this process and how it can benefit your business.