Introduction

Over 60% of industrial PLCs remain disconnected from cloud systems, creating costly data siloes that hamper real-time visibility and predictive maintenance. Traditional PLCs excel at local control but fall short when it comes to remote monitoring, advanced analytics, and seamless IT/OT convergence. Modern IoT industrial control systems bridge this gap by enabling PLC to cloud migration, delivering continuous data streams for smarter operations. In this article, we’ll explore how industrial control modernization leverages IoT retrofit solutions to unlock actionable insights and drive operational excellence.

Retrofitting Legacy PLCs: Hardware Interface Strategies

To embark on an industrial IoT transformation, compatibility with legacy equipment is paramount. Retrofitting legacy PLCs involves converting traditional industrial communication protocols (Modbus RTU/TCP, Profibus, or Ethernet/IP) into IoT-friendly formats like MQTT or OPC UA.

. Industrial IoT Gateways

Multi-protocol gateways—powered by SoCs such as NXP i.MX 8—serve as protocol translators, aggregating sensor data and securely forwarding it to the cloud. They provide serial and Ethernet ports, plus optional cellular connectivity for remote sites.

Multi-protocol industrial IoT gateways act as bridges between legacy PLCs and modern cloud infrastructures. Paired with modular PLC components for industrial control upgrades, they simplify retrofitting without costly system overhauls.

. Signal Conditioning Modules

Converting analog signals (4–20 mA, 0–10 V) into digital values ensures that every analog transmitter and actuator integrates seamlessly into an IIoT architecture.

. Non-Intrusive Retrofits

For environments where PLC downtime isn’t an option, non-invasive current clamps, acoustic sensors, and edge compute units can capture machine status—no rewiring required.

By focusing on PLC communication protocols, industrial IoT gateway selection, and Modbus to MQTT conversion strategies, you can retrofit existing control systems with minimal disruption and cost.

Intelligent Edge Computing: Filtering Critical Data

Edge data processing reduces bandwidth consumption and ensures real-time responsiveness—critical for industrial operations. Rather than sending every data point to the cloud, intelligent edge computing filters and preprocesses information at or near the source.

| Data Processing Mode | Latency | Bandwidth Demand | Ideal Use Case |

| Raw Data Streaming | < 50 ms | High | Precision motion control |

| Edge Pre-processing | 100–500 ms | Medium | Predictive maintenance |

- Edge Hardware Requirements

MCUs from the ARM Cortex-R series deliver deterministic performance for safety-critical tasks, while TSN-enabled switches (e.g., Marvell Prestera CX) guarantee synchronized, low-latency communication across the shop floor.

Devices like the NVIDIA Jetson Nano or ARM-based MCUs offer powerful edge inference capabilities. Engineers can find reliable industrial IoT modules and IC chips to build low-latency, real-time edge analytics systems.

- Data Optimization Techniques

- Deadbanding: Eliminates redundant value transmissions within a defined threshold, reducing network chatter.

- Edge AI Inference: Devices like the NVIDIA Jetson Nano can perform local anomaly detection and fault diagnostics, surfacing only critical alerts to the cloud.

By deploying industrial edge computing and PLC data filtering at the gateway layer, manufacturers can cut cloud ingress costs and accelerate decision-making.

Building Cloud-Ready Industrial Systems

A robust cloud integration architecture connects PLCs and sensors to scalable IoT platforms—AWS IoT, Azure IoT, or private cloud solutions—while maintaining security and reliability.

1. Layered Architecture

- Field Layer: PLCs, sensors, and actuators collect raw data.

- Edge Layer: Gateways and edge compute modules aggregate, filter, and secure data.

- Cloud Layer: Hosts data lakes, analytics engines, and applications (MES/ERP integration via REST APIs).

2. Secure Transmission Components

- Hardware Security Modules: ATECC608A chips enable device authentication and end-to-end encryption.

- Rugged Industrial Routers: IP67-rated appliances (e.g., Phoenix Contact FL mGuard) protect against dust, moisture, and cyber threats.

3. Cloud Platform Capabilities

- Digital Twins: Real-time replicas of machines facilitate performance monitoring and what-if simulations.

- API-First Design: RESTful endpoints tie IIoT data with enterprise systems, automating workflows and triggering work orders.

Adopting industrial cloud integration and IIoT security hardware ensures data integrity, regulatory compliance, and open connectivity for future-proof scalability.

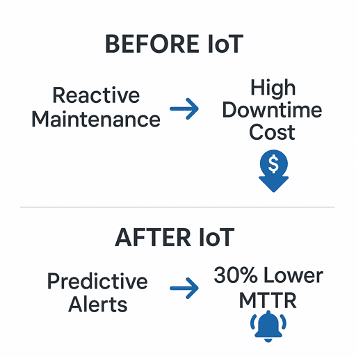

ROI-Driven Transformation: Cost vs. Value Metrics

Investing in industrial control modernization should deliver clear, quantifiable benefits. Successful digital retrofit projects typically demonstrate:

- Reduced Maintenance Costs: ABB reported a 45% decrease in unplanned downtime after deploying predictive maintenance algorithms on its PLC fleet.

- Improved Energy Efficiency: Schneider Electric customers achieved 12–18% average energy savings by monitoring power consumption at the edge and optimizing load schedules.

- Enhanced Overall Equipment Effectiveness (OEE): Real-time production analysis enabled by cloud analytics closes the loop on process optimization, driving throughput gains of up to 20%.

By embedding ROI analysis into project planning, you can justify retrofit budgets and prioritize high-impact assets for migration.

Phased Migration: Minimizing Operational Disruption

A structured implementation roadmap minimizes risk and ensures stakeholder buy-in:

1. Audit Phase (2–4 Weeks):

- Inventory PLC models, network topologies, and communication protocols.

- Use industrial packet sniffers (e.g., Wireshark Industrial Edition) to map existing traffic.

2. Pilot Phase (4–8 Weeks):

- Select a single production line or critical asset for gateway deployment (e.g., Siemens IOT2050).

- Validate data flow from PLC to cloud dashboards; refine data models.

3. Scale Phase (3–6 Months):

- Roll out gateway hardware across multiple lines; configure cloud rule engines for alerts and workflows.

4. Optimize Phase (Ongoing):

- Continuously update AI models based on historical data.

- Perform firmware compatibility checks before major PLC software revisions.

Risk Mitigation Tips:

- Segment OT and IT networks with VLANs to prevent broadcast storms.

- Maintain a firmware compatibility checklist to avoid version mismatches that could disrupt control loops.

Conclusion

Transforming legacy PLCs into cloud-connected assets isn’t about rip-and-replace—it’s about strategic enablement of your existing industrial backbone. By following a phased, ROI-driven approach—leveraging industrial IoT migration services and PLC cloud integration partners—you can modernize equipment cost-effectively, reduce downtime, and unlock the full potential of your operational data.