In the earlier days of vehicle engineering, engine remapping was part skill and part science. Engineers had to use carburettors (a device used by a gasoline internal combustion engine to control and mix air and fuel entering the engine) to mix air and fuel and then the mechanical breaker points to control ignition timing. Although for the time they were rather effective, they were limited things like wear and tear, changes in temperature and differences in air pressure as they could all affect how well the engine ran.

Today, the engines in our vehicles are much more advanced. They use computer-controlled systems to manage the air, fuel, and ignition with much greater accuracy. This modern technology allows engine’s to be remapped more specifically for better performance, fuel efficiency, and reliability. This is achieving things that were impossible decades ago.

The Limitations of Carburettors and Points

Carburettors worked by creating a vacuum, called the venturi effect, which pulled fuel into the airflow going into the engine. Small parts including jets and screws were used to adjust how much fuel mixed with air. When the process was like this, tuning a carburettor was physically changing these parts or tuning screws. This took a lot of skill and time as the engineer had to listen extremely carefully and rely on their experience to complete it correctly.

Changes in temperature, humidity, altitude could affect how the engine ran, meaning it would likely need to be re-tuned by hand.

Overall, the precision of these systems was very low. Carburettors could only get the air-fuel mix close to what was ideal, and the ignition timing could become even less accurate as the different parts wore down. The lack of precision meant engines couldn’t run as efficiently as they could, leading to lower performance and higher emissions.

Electronic Fuel Injection and Ignition Systems

Modern-day engines use electronic fuel injection and computer-controlled ignition systems as opposed to older mechanical parts. The newer systems rely on sensors that monitor important factors such as engine temperature, throttle position, oxygen levels in the exhaust, and air pressure. When the sensors pick up these stats, they are all sent to the Engine Control Unit (ECU) which is essentially the brain of the engine.

The ECU uses the data to constantly adjust how much fuel goes into the engine and when the spark plugs fire, making sure everything runs smoothly. Modern ignition systems, like coil-on-plug setups, have replaced the old mechanical points. The ECU controls the timing of the spark electronically, adjusting in real-time based on how the car is being driven at that time. this will result in better performance, improved fuel economy and lower emissions.

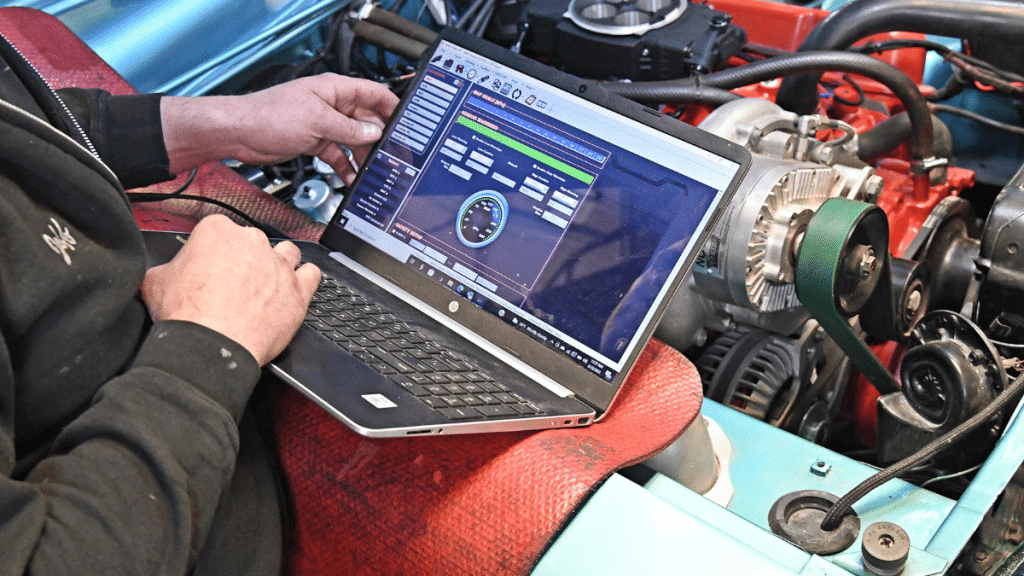

More Precise Tuning with Modern Tools

In today’s world, remapping an engine is much more about software than it is screwdrivers. Specialist engineers can do many things for your vehicle such as more horsepower, more torque, removing flat spots and improve fuel economy. This is all done by software and computer work which is far more precise and much easier for the engineer to perfect.

In conclusion

It is clear to see that the evolution from carburettors and mechanical points to electronic control systems has massively transformed engine remapping. Thanks to these huge advances, modern-day vehicles are more powerful, efficient, and environmentally friendly. These changes have definitely set a new standard for automotive performance.