As pool maintenance professionals face increasing demands for energy efficiency and reliability, the challenge of maintaining optimal pump performance becomes ever more critical. Aging pool pumps often struggle to balance power output with long-term durability, leading to increased maintenance costs and reduced efficiency. Modern electric pool pumps equipped with advanced motors offer a compelling solution to these challenges. This comprehensive guide explores essential motor specifications, proven strategies for extending equipment lifespan, and critical warranty considerations that every pool maintenance professional needs to understand. Whether you’re troubleshooting performance issues or selecting new equipment for clients, mastering these fundamental aspects will help you deliver superior results and maintain your competitive edge in the pool service industry.

The Critical Role of Powerful Motors in Electric Pool Pumps

Electric pool pump motors serve as the heart of efficient water circulation systems, with their performance directly impacting both operational costs and water quality. The relationship between torque and RPM is crucial – higher torque enables consistent water flow even under demanding conditions, while optimal RPM settings ensure proper filtration cycles. Variable-speed motors have revolutionized pool maintenance by offering dynamic performance adjustments, unlike traditional single-speed units that operate at full capacity regardless of need. For residential pools under 20,000 gallons, a 1-1.5 HP motor typically suffices, while larger pools up to 40,000 gallons require 2-2.5 HP for effective circulation. The impact on energy efficiency is substantial – variable-speed motors can reduce energy consumption by up to 80% compared to single-speed alternatives by matching power output to actual filtering requirements. Modern motors also incorporate advanced features like built-in diagnostics and thermal protection, ensuring sustained performance while preventing burnout during peak operation periods. Understanding these motor characteristics enables maintenance professionals to optimize pump operations, resulting in cleaner pools and significantly lower operating costs for their clients.

Decoding Pump Performance Specifications

Key Metrics for Maintenance Professionals

Understanding flow rate specifications is essential for optimal pump selection and operation. For residential pools, target flow rates typically range between 30-50 gallons per minute (GPM) per 10,000 gallons of pool volume. Head pressure, measured in feet of head, should maintain between 40-60 feet for most installations, with higher values indicating potential circulation issues. Energy Star certification requires a minimum energy factor of 3.8 for variable-speed models, making this rating crucial for efficiency assessments. Noise levels should remain below 60 decibels at three feet distance for residential installations.

Real-World Performance Testing Methods

Effective performance monitoring requires systematic testing protocols. Install pressure gauges on both suction and discharge sides of the pump, with readings taken at consistent times during operation. Flow meters should be positioned on straight pipe sections at least five pipe diameters from any fittings, ensuring accurate measurements. Track energy consumption through dedicated submeters or smart monitoring systems, recording baseline readings during peak and off-peak hours. Compare actual performance against manufacturer specifications monthly, noting any deviations greater than 10% for immediate investigation. Regular testing helps identify efficiency losses before they impact water quality or operating costs significantly.

Extending Electric Pool Pump Lifespan: Pro Maintenance Strategies

Implementing comprehensive maintenance strategies significantly extends electric pool pump longevity while maintaining peak performance. Leading manufacturers like iGarden recommend quarterly inspection of motor cooling systems, including ventilation ports and fan operation, with immediate cleaning of any debris accumulation to prevent overheating. Mechanical seals should undergo replacement every 3-4 seasons or upon signs of leakage, with careful attention to proper alignment during installation. Voltage stability plays a crucial role – install surge protectors rated for outdoor use and monitor supply voltage regularly, maintaining it within 10% of motor specifications. Corrosion prevention demands particular attention in coastal areas; apply marine-grade protective coating annually to exposed metal components and inspect monthly for signs of oxidation. The impeller and basket system needs weekly cleaning during peak season, with special focus on removing trapped debris that could cause cavitation. Establish a documented maintenance schedule that includes monthly amperage draw measurements to detect early signs of bearing wear or electrical issues. During winter months in seasonal locations, proper pump winterization prevents freeze damage through complete system drainage and motor protection. For year-round operation, maintain consistent chemical balance to prevent internal component degradation, and schedule professional inspections bi-annually to assess bearing condition and electrical connection integrity.

Replacement Policy and Warranty Analysis

Comparing Manufacturer Warranties

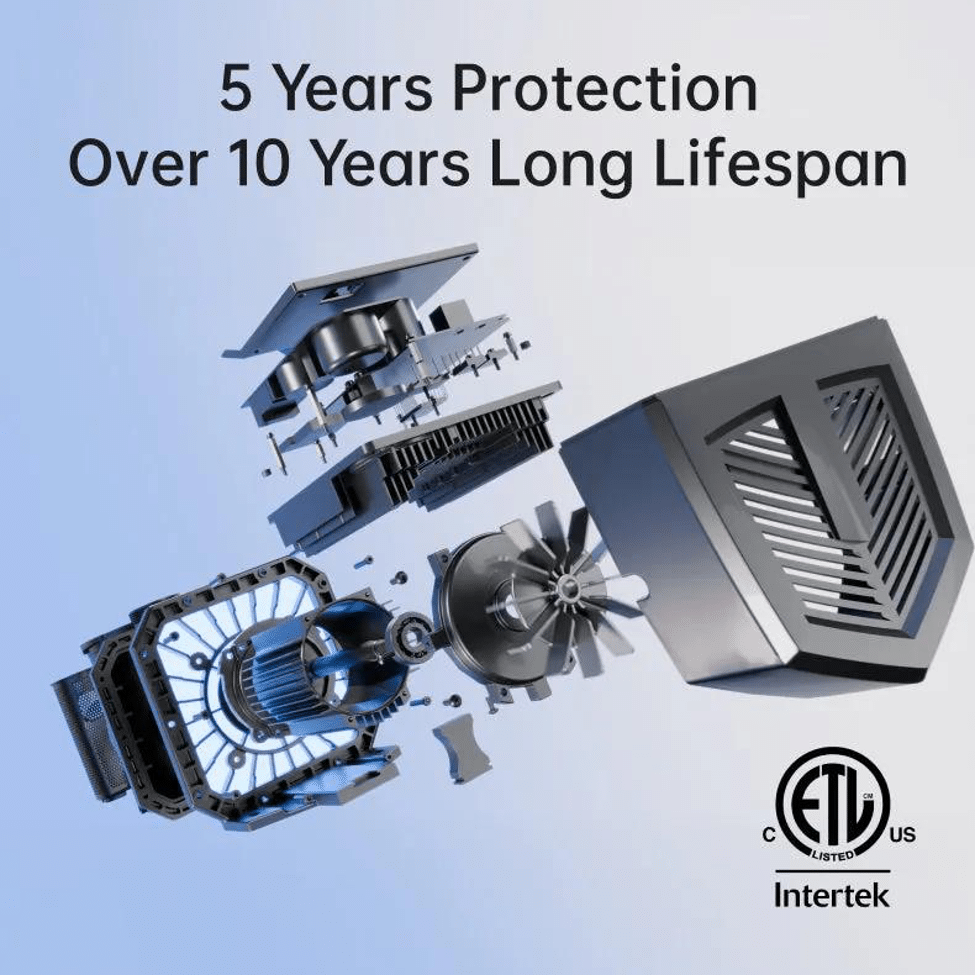

Pool pump warranty coverage varies significantly across manufacturers, with premium models typically offering 5-year protection compared to standard 3-year terms. Leading manufacturers include both parts and labor during the first year, transitioning to parts-only coverage thereafter. Key warranty exclusions often encompass damage from improper chemical balance, unauthorized repairs, and commercial usage. Additional exclusions include freeze damage in regions without proper winterization and failures due to voltage irregularities. Most warranties require professional installation documentation and proof of regular maintenance to remain valid.

Navigating Replacement Processes

Successful warranty claims require thorough documentation, including original purchase receipts, installation certificates from licensed professionals, and detailed maintenance logs showing regular service intervals. When filing a claim, submit photographs of the serial number, visible damage, and installation configuration. Most manufacturers require online claim registration within 30 days of discovering the issue, followed by professional diagnosis confirmation.

Professional Selection Guide: Balancing Power and Durability

Selecting the optimal electric pool pump requires a systematic approach focused on both immediate performance needs and long-term reliability. Begin by calculating pool volume requirements using the standard formula: length x width x average depth x 7.5 for rectangular pools. This baseline figure determines minimum flow rate requirements. When matching motor specifications to usage patterns, consider peak demand periods – summer months typically require 8-12 hours of operation versus 4-6 hours in cooler seasons. Carefully evaluate warranty terms beyond duration, focusing on coverage for environmental factors common in your region and manufacturer support infrastructure. Verify system compatibility by comparing pipe diameter specifications, voltage requirements, and mounting configurations with existing infrastructure. During installation, maintain proper clearances for ventilation (minimum 12 inches on all sides), install unions on both suction and discharge lines for easier maintenance, and ensure proper bonding to meet electrical codes. Position the pump below water level when possible to optimize priming efficiency, and install a check valve if elevation differences exceed 3 feet. These careful considerations during selection and installation establish the foundation for years of reliable operation.

Maximizing Pool Pump Performance: Key Takeaways

The relationship between motor power and durability remains fundamental to achieving optimal pool pump performance. Professional maintenance teams must carefully evaluate horsepower requirements, flow rates, and energy efficiency ratings when selecting equipment for their clients. Variable-speed motors with advanced protection features represent the gold standard for modern installations, offering superior energy savings and operational flexibility. Critical selection factors include accurate pool volume calculations, detailed analysis of usage patterns, and thorough evaluation of warranty coverage. Remember to verify system compatibility and follow proper installation protocols to ensure long-term reliability. Take action today by conducting comprehensive performance audits of your existing pool pump installations – identify opportunities for efficiency improvements, implement structured maintenance schedules, and document all service activities to protect warranty coverage. Your expertise in matching powerful, durable motors with specific pool requirements will continue to differentiate your service in an increasingly competitive market.