When people think about the strong parts of a building, they usually picture the walls or the roof. Maybe big beams, steel frames, or fire doors. But one of the most important—and toughest—parts is actually the floor. Not just the surface you walk on, but what’s hidden underneath it.

There’s a whole layer of stuff down there: pipes, wiring, drainage systems, even HVAC equipment in some buildings. And the only way to reach all that safely? Floor access points. More specifically, the kind built to take a beating—day after day.

What Makes Floor Access So Important?

In buildings like data centers, airports, factories, or large offices, the space under the floor isn’t empty. It’s packed with stuff that makes the whole place work. Think power cables, water lines, communication wiring—things you don’t want just lying out in the open.

Eventually, someone needs to get under there. For repairs, upgrades, inspections—you name it. And when that happens, they need to do it quickly and safely, without tearing up the floor or stopping everything else going on.

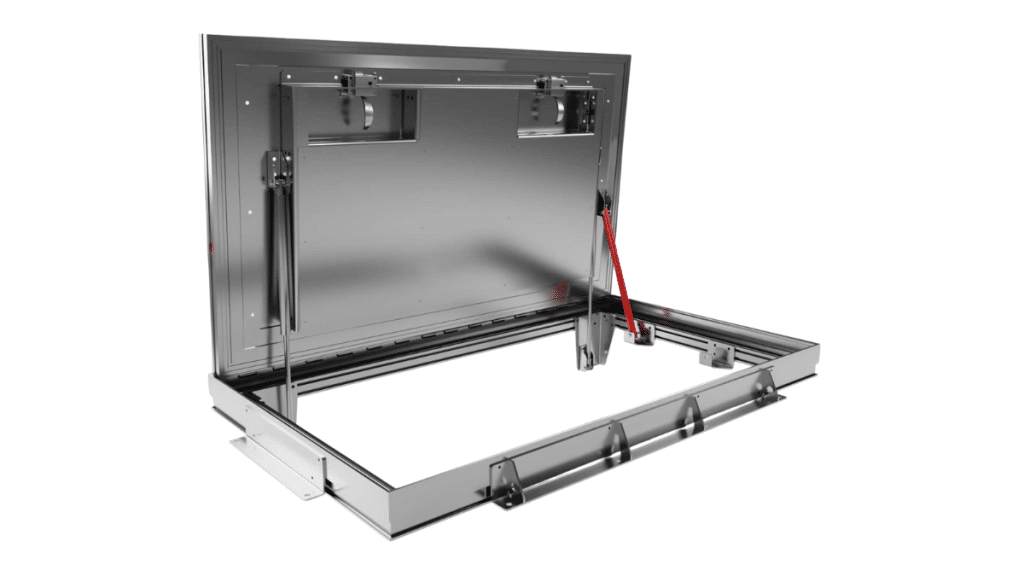

That’s where heavy-duty floor access comes in. These aren’t flimsy panels you pry up with a screwdriver. They’re built to handle real loads—equipment, foot traffic, even forklifts—without cracking, shifting, or getting in the way.

The Wrong Type of Hatch Can Cause Big Problems

If the access cover isn’t strong enough, it doesn’t just wear out fast. It can actually get dangerous.

Imagine a worker rolling a heavy cart across a hatch that wasn’t made for it. If the panel shifts or bends, they could fall. Or worse, the gear they’re moving could tip over. Now you’ve got injuries, broken equipment, and downtime. All because the access system couldn’t handle normal use.

Even in places with less weight, a cheap or badly-fitted hatch might not seal properly. That can let in dust, moisture, or even pests—stuff that really shouldn’t be near wiring or data systems. In some cases, it can also mess with a building’s fire safety or airflow controls.

What Makes a Floor Hatch “Heavy-Duty”?

It’s more than just being thick or heavy. A real heavy-duty access cover is designed for specific loads. That could mean constant foot traffic, rolling carts, heavy tools, or even industrial vehicles like forklifts.

They’re often reinforced with steel or aluminum and designed to stay level with the floor, so nothing gets caught or damaged as people move around. They usually have secure locking mechanisms and proper seals to keep things clean, dry, and safe.

In places like food production or chemical storage, some covers also need to resist corrosion or follow hygiene rules. And in tech-heavy spaces, like server rooms, they might even need grounding points or anti-static coatings.

These Access Points Don’t Get Noticed—Until Something Goes Wrong

Here’s the thing: when floor access works well, no one thinks about it. It blends in. It doesn’t squeak, shift, or stand out. But the minute it starts to fail—if a panel sticks, cracks, or doesn’t line up—it becomes a real issue.

If you’ve ever seen someone struggling to lift a warped floor panel or trying to clean around one that doesn’t shut right, you get it. It’s annoying, it slows things down, and it creates a weak point in a space that’s supposed to stay safe and smooth.

That’s why getting it right the first time is so important. A solid, durable hatch might cost more upfront, but it saves a lot of time, repairs, and stress later on.

Why Planning Ahead Matters

Adding or replacing floor access after a building is done is tough. You’re cutting into a finished floor, which means more mess, more downtime, and usually more money. But when it’s built in from the start—and sized for the real weight and use of the space—it just works.

Good planning also means putting hatches where they’re actually needed. That means close to major systems, not stuck in a random corner. It also means making sure they match the floor finish, so nothing looks out of place or gets in the way.

Built to Handle the Real World

Heavy-duty floor access points aren’t fancy. But they’re reliable. And in places where people work hard, move fast, or need to get under the floor often, that reliability matters.

It’s not just about strength. It’s about safety. About saving time. About making sure the parts of a building people don’t see are just as solid as the ones they do.

So yeah, the toughest parts of the building might not be the ones up high. They might be right under your feet—and they’re doing a lot more than most people ever realize.