As global plastic pollution worsens, scientists are trying to discover sustainable alternatives. A team of researchers at the University of Houston and Rice University in the United States has made a breakthrough and successfully transformed biodegradable bacterial cellulose into a multifunctional super material that can replace traditional plastics.

Research Process and Findings

The new material is based on bacterial cellulose (BC), a naturally occurring and totally degradable biopolymer. By new biosynthesis techniques, the researchers used fluid shear forces in a rotating culture device for synthesizing tough bacterial cellulose sheets with aligned nanofibers. The material exhibits superior mechanical properties of high tensile strength, flexibility, foldability, and optical transparency, as well as long-term stability.

For enhancing performance, the team also incorporated boron nitride nanosheets (BNNS) into the culture medium to form hybrid bacterial cellulose-boron nitride nanofilms. Tests revealed tensile strength of approximately 553 MPa and a three times faster heat dissipation rate than conventional samples, once again expanding its utility for high-stress or high-temperature applications.

The material has broad application prospects, for example, green packaging, water bottles, medical dressings, and even green electronics and energy storage devices. The researchers emphasized that the one-step, scalable fabrication process offers the foundation of industrial applications. It will potentially replace plastics in many fields in the future and alleviate environmental pollution.

Two Key Materials

What Are Boron Nitride Nanosheets (BNNS)?

Boron nitride nanosheets are a 2D nanomaterial with a graphene-like structure, composed of alternating boron (B) and nitrogen (N) atoms in a hexagonal honeycomb lattice. According to bonding arrangements, boron nitride exists primarily as two crystalline forms:

l Hexagonal Boron Nitride (h-BN): Most stable allotrope, structurally similar to graphite and often termed “white graphene.” It possesses high thermal conductivity, electrical insulation, chemical inertness, and decent mechanical properties.

l Cubic Boron Nitride (c-BN): With diamond-like hardness, it is used for ultra-hard coatings.

Properties of Boron Nitride Nanosheets:

l High thermal conductivity: ~600 W/m·K, superior to most materials

l Electrical insulation: bandgap ~5-6 eV, suitable for use as insulating layers in electronic devices

l Chemical stability: resistant to high temperature, oxidation, and corrosion

l Mechanical strength: high

l Lubricity: low friction coefficient due to interlayer easy shear

What Is Bacterial Cellulose (BC)?

Bacterial cellulose is a natural nanofiber polymer synthesized by certain microorganisms (e.g., Komagataeibacter xylinus). It has the same chemical structure as plant cellulose (β-1,4-glucan) but a unique ultrafine 3D network structure.

Key Properties:

l Ultrafine fiber network: 3–100 nm fiber diameter—1,000 times thinner than plant cellulose (10–50 μm)—as a highly porous (>90%) gel membrane.

l High purity: Free from impurities present in plants like lignin and hemicellulose, with good biocompatibility.

l High strength and water absorption: 200–300 MPa wet-state tensile strength, 100–200 times own weight water absorption capacity.

l Tunability: Fiber thickness, porosity, etc., can be regulated by culture conditions (e.g., medium, temperature).

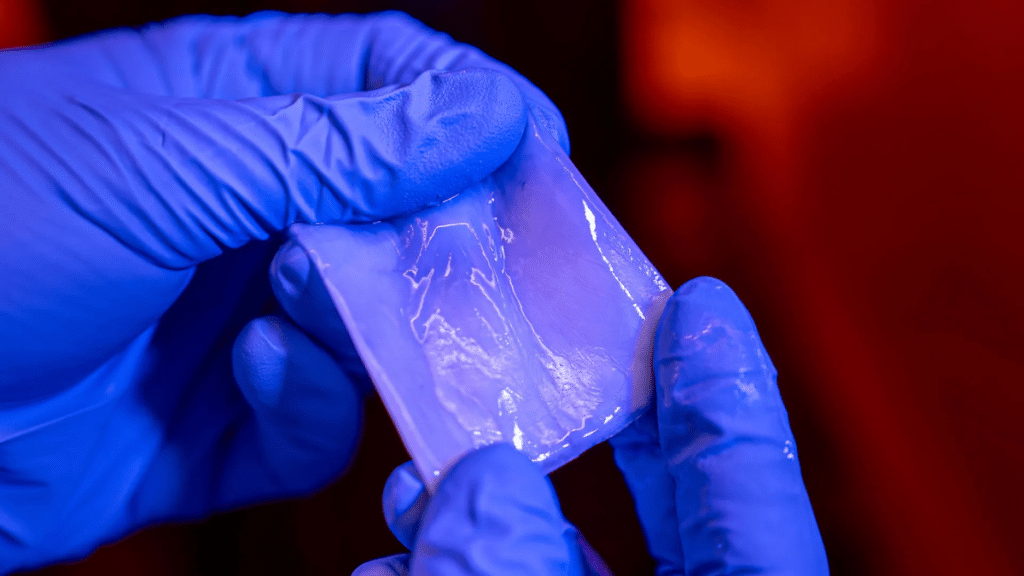

A wet microbial cellulose pellicle being removed from a culture, from Wikipedia

Conclusion

This research combines the multidisciplinary strengths of materials science, biology, and nanoengineering, illustrating a novel pathway for sustainable materials innovation. As the technology continues to evolve, this super material may be one of the final answers to plastic pollution. Stanford Advanced Materials (SAM), as a supplier of advanced materials, is always tracking the latest scientific developments. SAM provides high-purity materials to help researchers push the boundaries of science.