Choosing an injection molding supplier can feel deceptively simple—until it goes wrong.

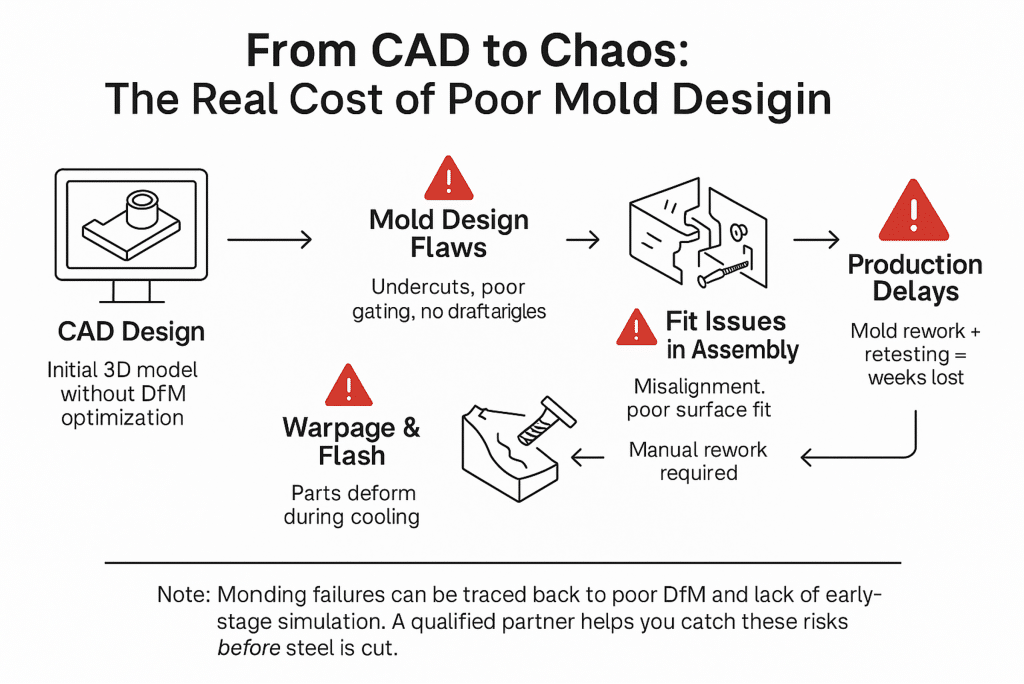

Maybe the first production batch doesn’t fit your mating parts. Maybe the mold flashes, or warps, or takes twice as long to cool as promised. Maybe you can’t get updates, or worse, you don’t even know where the mold was made.

That’s because injection molding isn’t just a service—it’s a process rooted in engineering discipline. And picking a custom injection molding service isn’t about finding someone who “can do plastic parts.” It’s about choosing a partner who can flag risks early, hold tolerances at scale, and communicate like a technical extension of your team.

So how do you filter signal from noise when evaluating vendors?

Use these five criteria. They’ll help you avoid surprises, align expectations, and select a molding partner who can support your product from first article to full production.

Standard 1: Engineering-Driven DfM that Prevents Rework

Design-for-Manufacturing (DfM) is where risk gets reduced—or embedded.

Before tooling begins, your molding partner should actively analyze your CAD for trouble spots: uneven wall thickness, unsupported ribs, zero-draft bosses, weld lines, and undercuts. If a vendor’s response to your files is simply “looks fine,” that’s not confidence—it’s avoidance.

The best suppliers provide visual feedback, such as mold flow simulations or annotated CAD callouts. They ask clarifying questions. They may even suggest geometry tweaks that reduce tooling complexity or prevent ejection issues. That’s the kind of support that saves weeks in rework later.

Ask yourself:

- Did they raise any issues—or just agree with everything?

- Are they willing to explain why certain features may not mold consistently?

- Can they offer alternative gate or parting line options?

Good DfM doesn’t slow you down. It’s how you avoid tooling a bad idea into steel.

Standard 2: CNC Precision Aluminum Parts + Molding – Integrated for Fit and Speed

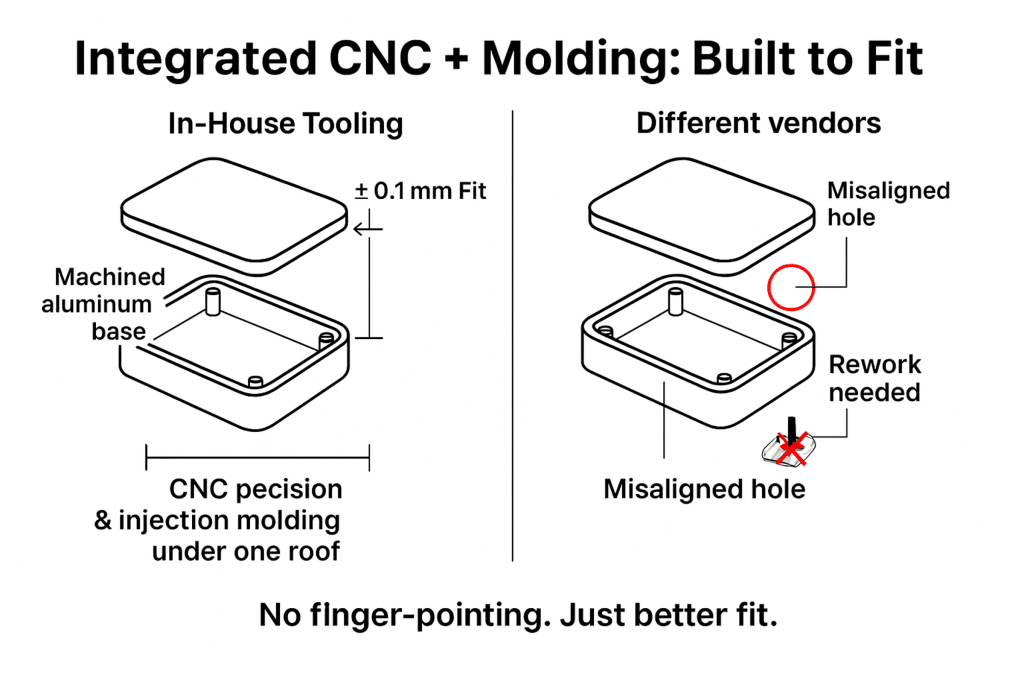

Plastic components don’t operate in isolation. Whether you’re designing a smart device, a handheld controller, or a sensor enclosure, chances are your injection-molded part needs to align precisely with a metal structure—like a CNC-machined aluminum bracket, heatsink, or internal frame.

That’s where integrated capabilities truly shine. A supplier who can provide both injection molding and CNC precision aluminum parts offers more than convenience—they offer engineering alignment.

When one team handles both materials, you get:

- Better tolerance control across plastic and metal fits

- Matched finishes that align cosmetically and functionally

- Fewer cross-vendor delays or “fitment blame games”

For startups, industrial designers, or lean product teams, this kind of integration means fewer emails, clearer accountability, and assemblies that come together as planned.

Instead of chasing two factories to fix a mismatched hole pattern or rework mounting bosses, you get coordinated manufacturing—and faster time to market.

Ask your supplier:

- Do they machine aluminum 6061 or 7075 in-house?

- Can they provide anodizing, tapping, or press-fit installation?

- Can they kit or pre-assemble your parts to simplify your workflow?

When molding and CNC live under one roof, fit isn’t just a goal—it’s part of the process.

Standard 3: Mastery of Materials and Complex Mold Techniques

Not all plastics behave the same—and not all factories can handle the tough ones.

If your design uses polycarbonate, nylon, POM, or TPEs, you’ll need a supplier that understands how these resins behave under pressure. That includes drying protocols, barrel temperature stability, shear sensitivity, and cooling curve management. These variables affect everything from surface finish to strength to dimensional accuracy.

Material expertise is only part of the challenge. What about the mold itself?

Insert molding, overmolding, side-action cores, lifters, and multi-shot designs all require experience—not just capability claims on a website. The supplier should be able to show physical parts or case studies involving these techniques.

Ask questions like:

- Can they walk you through their experience molding your chosen resin?

- Have they handled comparable mold complexity (e.g., moving cores, unscrewing threads)?

- How do they manage cooling for asymmetrical or thick-walled parts?

Choosing a supplier without this depth is like hiring a chef who says “Sure, I’ve cooked fish”—without asking what kind, or how you’d like it done.

Standard 4: Dimensional Accuracy Backed by Real Quality Data

A glossy sample means nothing if the 5,000th unit doesn’t fit.

That’s why your supplier’s QA system matters just as much as their machines. ISO 9001 certification is a good start, but it doesn’t guarantee repeatable accuracy. You need process-level controls and traceable results.

Look for:

- First Article Inspection (FAI) reports tied to your specific drawing

- CMM or digital caliper readings across multiple cavities

- Statistical process control (SPC) charts or capability studies

- Documentation of deviation handling, corrective actions, and batch quarantining

Don’t accept vague assurances like “we check everything.” Ask for examples. What does a typical QA report look like? How often are inspections performed? Are there defined limits for rework or rejection?

True quality is built into the process—not inspected in after the fact.

Standard CNC Precision Aluminum Parts + Molding – Integrated for Fit and Speed5: Optional CNC Capability That Adds Real Integration Value

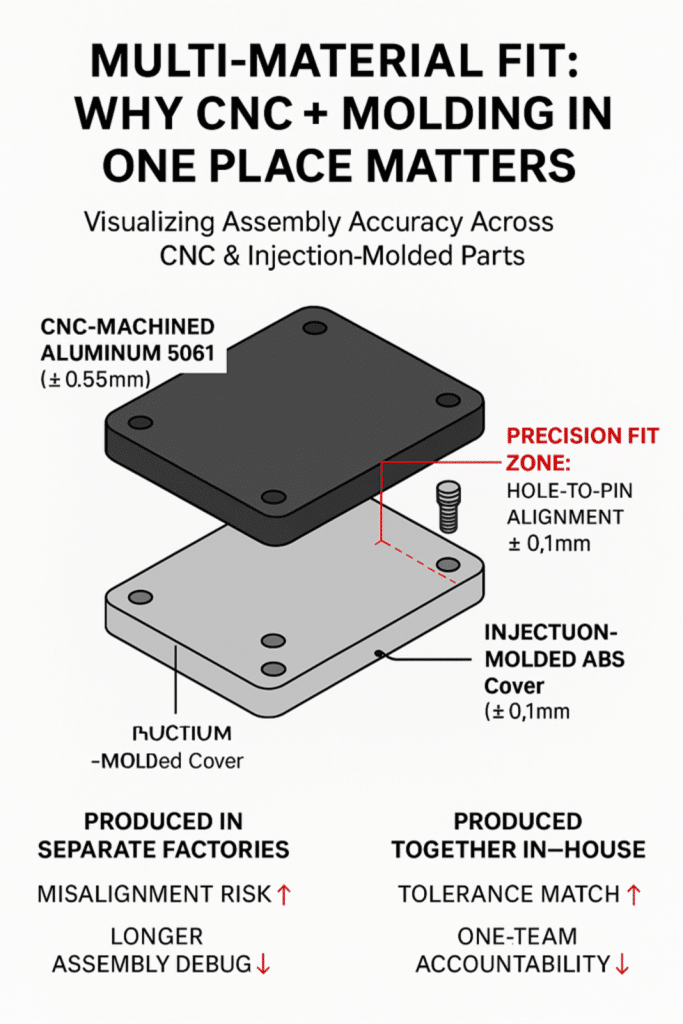

Here’s a bonus that’s often overlooked—until your plastic part has to align with a metal one.

If your project includes components like aluminum heatsinks, brackets, or structural frames, it’s worth finding a molding partner who also offers precision machining. Not because you need to consolidate suppliers, but because doing so often improves fit, communication, and lead time coordination.

When your supplier also produces CNC precision aluminum parts, tolerance alignment improves. Surface finish compatibility increases. And if something doesn’t fit, there’s no finger-pointing—just faster resolution.

Ideal when:

- Plastic and metal parts need to assemble with zero clearance

- You’re running lean and can’t manage two separate supply chains

- You want parts delivered kitted or pre-assembled

This isn’t a requirement for every project. But if your BOM spans multiple materials, CNC capability is a signal that the supplier isn’t just “injection-molding-only”—they think like a systems integrator.

Conclusion: Standards Protect Your Project—Use Them

Injection molding is deceptively complex. You don’t just need a quote—you need confidence.

By evaluating potential suppliers against these five standards, you’ll avoid the costly missteps that come from vague promises and surface-level capabilities. You’ll identify partners who think ahead, communicate clearly, and treat your product like an engineering responsibility—not a commodity job.

Quick Recap:

- DfM insights that prevent bad designs from becoming bad molds

- Tooling control that keeps schedules, specs, and ownership clear

- Materials + mold complexity expertise proven with real examples

- Dimensional accuracy backed by verifiable QA reports

- Integrated CNC for teams needing multi-material alignment

So before you send your next RFQ, pause and ask:

Are you choosing the fastest quote—or the most capable partner?

If you want your product to launch on time, perform reliably, and scale without surprises—choose based on standards, not assumptions.