In the packaging industry, product integrity is critical. Even a minor leak can cause contamination, shorten shelf life, and lead to expensive recalls. This is why many companies now invest in a package leak tester to ensure their packaging meets the highest quality standards.

What Is a Package Leak Tester?

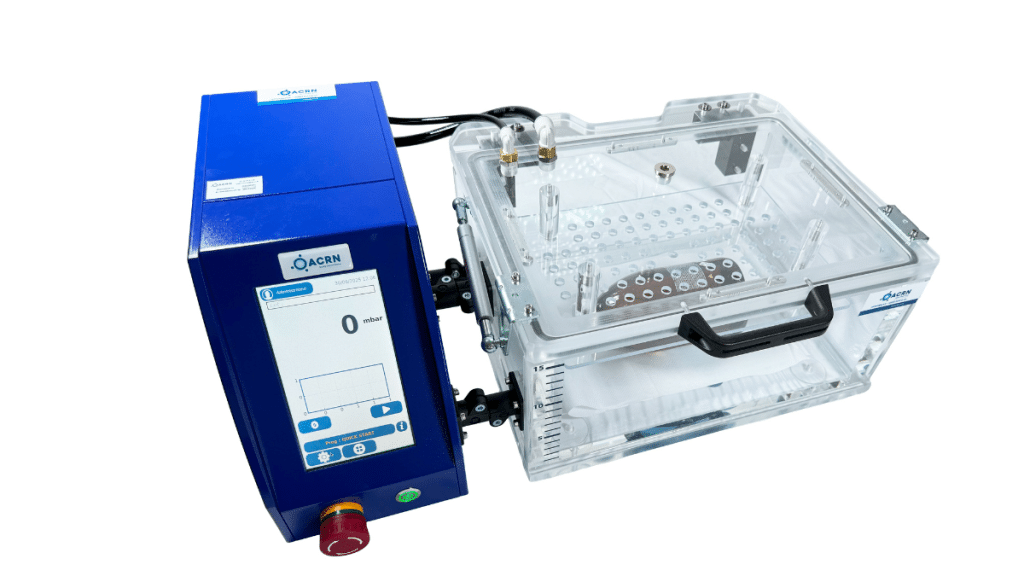

A package leak tester is a device designed to detect leaks in flexible or rigid packaging. The package is placed in a sealed vacuum chamber, and air is evacuated to create a vacuum.

If the package has a leak, the pressure change or visible bubbles will reveal it instantly.

This method is:

- Accurate – detects even micro-leaks

- Fast – ideal for production line spot checks

- Non-destructive for most flexible packaging

Why Use One in Your Packaging Process?

Implementing a package leak tester brings several benefits:

- Improved quality control – identify sealing defects before products leave your facility

- Waste reduction – fewer defective products reaching the market

- Regulatory compliance – align with industry guidelines like theExample of the D6653 standard

- Brand protection – avoid customer complaints and recalls

Choosing the Right Package Leak Tester

Not all leak testers are the same. Factors to consider include chamber size, automation level, and whether you need data recording for compliance purposes.

We offer a wide range of models to suit different industries, from food and beverages to pharmaceuticals and cosmetics.

Discover our full selection here: Discover our package leak tester.

Final Thoughts

In today’s competitive market, a package leak tester is not a luxury – it’s a necessity for ensuring packaging integrity, customer satisfaction, and long-term profitability.