Introduction

A past visit to manufacturing facilities clearly revealed the limitations of traditional rigid grippers. While efficient for repetitive tasks with standardized objects, they struggle to handle delicate or irregularly shaped items. For instance, in food processing and 3C electronics manufacturing assembly, they often cause damage. In 3C assembly, the rigid jaws of traditional grippers may apply uneven pressure, easily cracking fragile circuit boards or misplacing tiny components, highlighting the need for more versatile gripping solutions.

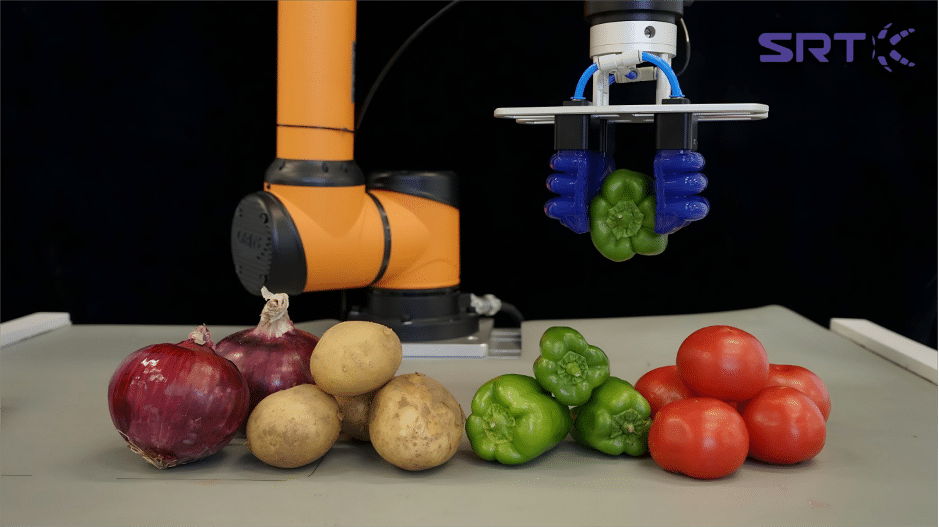

Soft grippers answer this need. Inspired by human hand dexterity, they conform to various object geometries, enabling precise handling of fragile items. Widely used in high – tech production and research, these grippers are revolutionizing automation, and this article delves into their capabilities.

How Do Soft Grippers Work

Soft grippers owe their functionality to carefully selected materials and intelligent design. Silicone, with its high elasticity, can stretch and deform to fit diverse object shapes, while also resisting chemicals and extreme temperatures. Its molecular structure allows for repeated stretching without permanent deformation, similar to a high – quality elastic. In contrast to rubber, silicone maintains its flexibility even in low – temperature environments, making it suitable for cold – storage applications, like handling frozen food products. This makes it ideal for applications like pharmaceutical manufacturing, where handling glass vials with medications requires both flexibility and chemical stability. Rubber, on the other hand, offers excellent grip due to its unique surface texture and elasticity. In the automotive industry, nitrile rubber – based soft grippers can securely grasp oily engine parts, preventing slippage during handling.

For actuation, soft grippers mainly rely on pneumatic or hydraulic systems. Pneumatic actuators, using compressed air, provide quick response times, making them perfect for high – speed operations like a bottling line, where they can rapidly pick and place bottles. Hydraulic actuators, leveraging fluid pressure, generate higher forces, enabling the handling of heavy objects, such as concrete blocks in construction. Some advanced models combine both systems for enhanced versatility, allowing for precise control in a wide range of tasks. For example, in precision assembly tasks, the pneumatic system can be used for the initial gentle approach and grip, while the hydraulic system steps in to provide additional force for more secure holding during subsequent operations.

Soft Grippers VS Traditional Grippers: Unveiling the Superior Advantages

Adaptability

Traditional grippers, designed for specific tasks, struggle when faced with diverse object shapes. In a furniture plant, a gripper for rectangular chair frames fails to handle curved armrests, requiring manual replacement that can take up to an hour and halt production. Soft grippers, however, adapt to various shapes. In smartphone manufacturing, a single soft gripper can handle components of different models, streamlining production and reducing costs by up to 30% according to industry reports. This adaptability allows for faster product turnaround and greater production flexibility. Take the example of a consumer electronics factory that frequently updates its product designs. With soft grippers, they can quickly switch from manufacturing one model with a sleek, rounded design to another with sharp, angular edges, without significant production interruptions.

Safety

Rigid, metal – constructed traditional grippers pose risks during malfunctions. A software glitch can cause excessive force, damaging delicate items or injuring workers. In fact, studies show that traditional gripper – related accidents account for 15% of industrial robotic incidents. Soft grippers, with their compliant design, act as shock absorbers. In a warehouse’s collaborative robot setup, they minimize harm if a robot collides with a human. In surgery, they reduce tissue damage during robotic – assisted procedures, improving patient outcomes. In a recent clinical trial, the use of soft gripper – enabled surgical robots reduced post – operative tissue inflammation by 20% compared to traditional robotic surgical tools, demonstrating their potential to enhance surgical precision and patient recovery.

Precision

Traditional grippers’ rigid jaws apply uneven pressure, endangering delicate microelectronics components. A miscalculation can crack an integrated circuit during placement, resulting in costly production losses. Soft grippers conform to objects, distributing force evenly. In watchmaking, they handle tiny gears without deformation, and in semiconductor manufacturing, they place silicon wafers with sub – micrometer precision. This precision reduces component damage rates by over 80% in some high – tech production lines. In the production of advanced microchips, where the margin for error is minuscule, soft grippers have enabled manufacturers to increase their yield rates significantly. By ensuring that each component is handled with the utmost care, they have contributed to the production of more reliable and high – performance electronic devices.

Applications of Soft Grippers

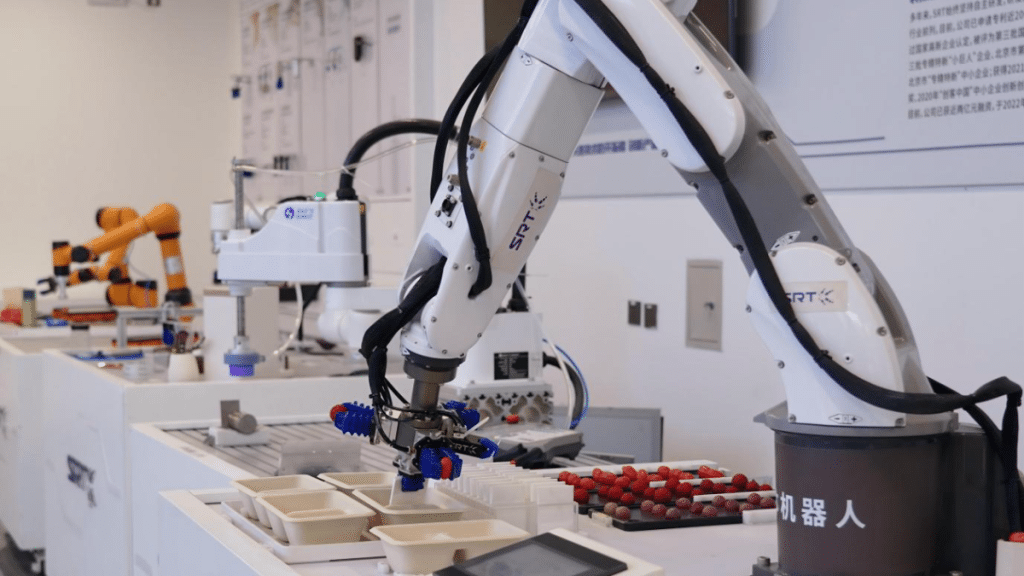

In the food industry, soft grippers handle fresh produce and pastries without damage. In 3C manufacturing, they assemble delicate electronics components with precision. In healthcare, they assist in surgeries and patient rehabilitation. For example, in heart bypass surgery, they hold blood vessels during grafting, and robotic hands with soft grippers aid stroke patients in regaining motor skills.

These grippers also benefit the injection molding, aerospace, and jewelry industries. They remove molded parts without deformation, handle carbon fiber composites in aircraft assembly, and pick up precious gemstones for jewelry setting. Additionally, soft grippers are increasingly used in underwater exploration to handle delicate marine specimens, and in disaster relief efforts to carefully retrieve damaged items, showcasing their expanding range of applications. In underwater archaeological excavations, soft grippers have been used to carefully lift ancient artifacts from the ocean floor, preserving their integrity. In disaster – stricken areas, robots equipped with soft grippers can sift through rubble to find survivors’ belongings or important documents, minimizing damage during the retrieval process. In education and research, soft grippers serve as teaching tools and are used to develop new robotic technologies.

Market Outlook

The market for soft grippers is growing rapidly, driven by the need for manufacturing flexibility, safer human – robot collaboration, and technological advancements. As companies seek to produce customized products efficiently, the demand for soft grippers that can handle diverse objects without retooling will continue to rise. The global soft robotics market, including soft grippers, is projected to reach 2938.53 million by 2033, growing at a CAGR of 26.6% from 2025 to 2033. Emerging trends, such as the integration of artificial intelligence and sensor technologies with soft grippers, are expected to further expand their capabilities and market reach, opening up new opportunities in sectors like smart home automation and personalized healthcare devices.

Conclusion

Soft grippers mark a significant advancement in robotics, enhancing flexibility, adaptability, safety, and precision across multiple industries. As automation progresses, they will play an increasingly vital role in shaping future manufacturing and other sectors, driving innovation and transforming task execution.