Introduction

Excavators are some of the most versatile machines in the construction and dredging industry. Their adaptability comes from the wide range of bucket types designed to handle different tasks, from digging and grading to material handling and dredging. Each bucket type is engineered with specific applications in mind, allowing operators to maximize efficiency and accuracy on site. Among these, Clamshell Buckets stand out as a highly specialized tool for material handling and dredging operations. These attachments are also part of broader excavator material handling attachments, offering industries reliable solutions for bulk movement and precision operations.

General-Purpose Buckets

General-purpose buckets are among the most widely used attachments for excavators. Designed for light to medium digging, loading, and material handling, they are ideal for projects such as roadwork, landscaping, and utility construction. Their durability and versatility make them a common choice in everyday excavation tasks.

Rock Buckets

When projects involve harsh conditions, such as quarrying or breaking through rocky terrain, rock buckets are the preferred choice. Built with reinforced structures and stronger teeth, they can handle abrasive material with ease. Their ability to withstand heavy impact makes them essential in mining, demolition, and large-scale construction projects.

Grading Buckets

Grading buckets are designed for smoothing and leveling surfaces rather than digging. Their wider and flatter shape provides precision in creating clean finishes on roads, foundations, and landscaping projects. They are particularly useful for contractors working on projects that require surface refinement and accuracy.

Trenching Buckets

Trenching buckets are narrower in design, enabling operators to dig precise trenches for utility lines, irrigation systems, and pipelines. They are efficient for projects that require uniform trench depths while minimizing excess material removal. Their design allows operators to save time and reduce material handling costs.

Clamshell Buckets In Material Handling and Dredging

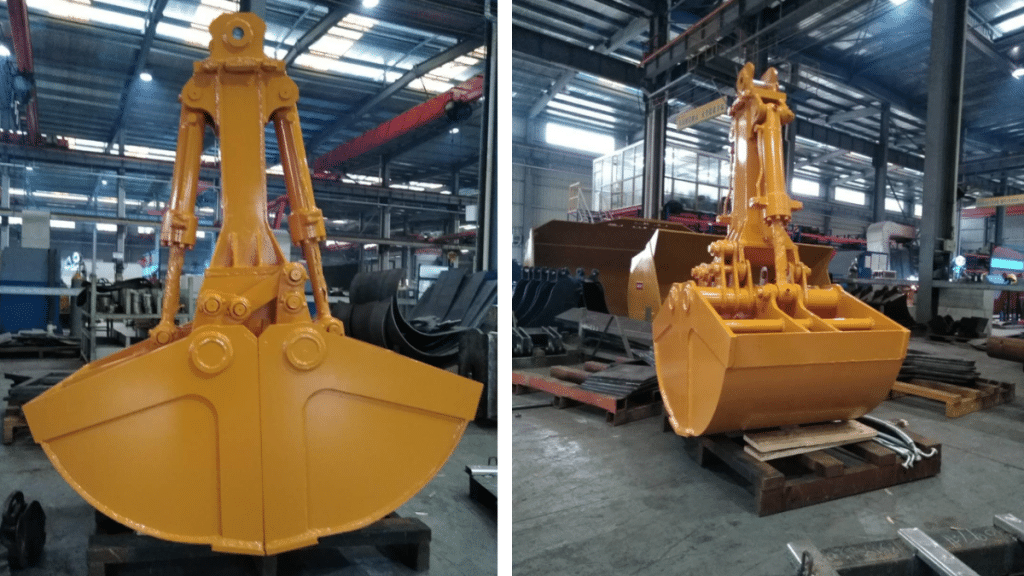

Among specialized excavator attachments, Clamshell Buckets are one of the most valuable for industries that require precise loading and unloading of bulk materials. Unlike traditional digging buckets, clamshell designs feature two hinged jaws that open and close, allowing controlled handling of soil, gravel, sand, or dredged material. These are considered essential excavator material handling attachments in industries focused on bulk movement and controlled placement.

In dredging operations, Clamshell Buckets are essential for removing sediment and debris from riverbeds, harbors, and construction sites near waterways. Their design ensures minimal spillage and accurate placement, making them ideal for both environmental projects and large-scale industrial dredging. As part of dredging and excavation tools, clamshell designs are widely relied on for efficient underwater operations.

In construction and industrial projects, they play a key role in loading bulk material into trucks, managing stockpiles, or transferring material where precision is critical. Hawk Excavator provides clamshell attachments that are built to handle challenging conditions while ensuring reliable performance across industries. Their range also includes solutions tailored for hydraulic clamshell bucket applications, ensuring contractors achieve efficiency in demanding projects.

Heavy-Duty Buckets

For demanding excavation tasks, heavy-duty buckets are built to withstand extreme workloads. These buckets are common in large infrastructure projects, mining operations, and any application requiring continuous digging of abrasive or compact material. Their reinforced cutting edges and strong side panels make them durable against long-term wear.

Skeleton Buckets

Skeleton buckets are designed with gaps between the bucket ribs, enabling separation of fine material from larger debris. They are particularly useful in recycling projects, land clearing, and sorting operations where material needs to be filtered during excavation.

Specialty Applications and Custom Solutions

Beyond standard options, specialty buckets exist for tasks such as dredging, handling scrap, or working in extreme conditions. Companies like Hawk Excavator recognize the importance of tailoring bucket designs to meet unique project requirements. Whether through customized Clamshell Buckets for dredging or modified trenching tools for utility projects, specialized attachments expand the capabilities of excavators in multiple industries. This includes advanced hydraulic clamshell bucket applications that are often deployed in ports, harbors, and bulk material transfer projects.

The Value of Choosing the Right Bucket

Selecting the right excavator bucket is about more than just digging—it directly impacts productivity, safety, and project timelines. Using a grading bucket where a rock bucket is required can lead to equipment wear or project delays. Similarly, employing Clamshell Buckets in dredging or material handling ensures accuracy, efficiency, and reduced waste. These versatile attachments prove their worth as part of effective dredging and excavation tools across multiple industries.

For industries that require adaptability, the role of brands like Hawk Excavator is crucial. Their focus on durable and efficient attachments provides contractors with tools suited for both everyday use and specialized industrial applications. With their strong reputation for designing reliable excavator material handling attachments, Hawk Excavator continues to serve contractors handling demanding excavation and dredging tasks.

Conclusion

Excavator buckets are not one-size-fits-all tools. From general-purpose digging to precision dredging and material handling, each bucket type serves a distinct purpose. Clamshell Buckets, in particular, demonstrate how specialized designs can expand the range of excavator applications, especially in dredging and bulk material management. As industries continue to demand versatility and efficiency, reliable solutions from manufacturers such as Hawk Excavator ensure that excavators remain indispensable across construction, dredging, and excavation tools, and industrial projects.