production efficiency means making merchandise faster, higher, and at a decreased fee. It makes a speciality of decreasing waste, saving electricity, and enhancing techniques. agencies purpose to supply greater with fewer resources.

The producing world is converting fast. New technologies and strategies are reworking how factories paint. Organisations that adopt these traits can stay in advance and improve profits. Ignoring them can make companies fall behind.

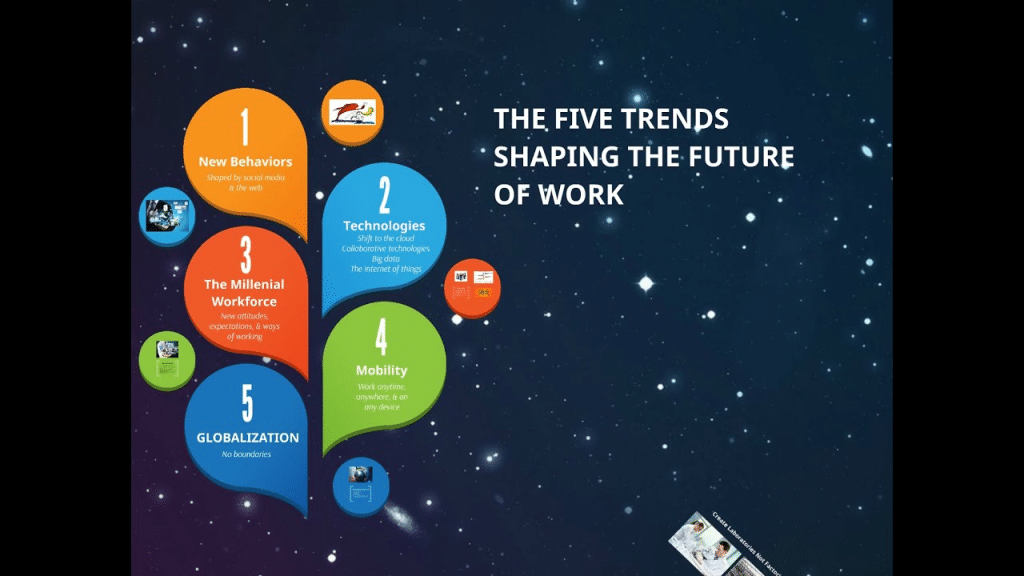

In this article, we are able to explore five key manufacturing efficiency developments. These tendencies are shaping the destiny of production. know-how they can assist organizations improve performance and stay competitive.

Choosing the Right Tool for Better Efficiency

The same principle applies across sectors, the closer a tool is to the specific challenges of a process, the greater the efficiency gains. This idea applies even in everyday workshop or home-use equipment, where understanding the differences between tools can shape performance and workflow; for example, comparing electric and gas log splitters can help determine which option better aligns with operating needs.

comparing electric powered and gasoline log splitters indicates how every works. This enables you to pick out the fine one for your wishes. selecting accurately improves workflow and performance.Choosing wisely improves workflow and performance.

1. Automation and Smart Machinery

Automation uses machines to do tasks with less human effort. Smart machinery can adjust itself and work more efficiently. This helps factories produce faster and reduce mistakes. It also saves time and lowers costs.

Key benefits include:

- Faster production and higher output

- Fewer errors and better quality

- Reduced labor costs

- Real-time monitoring of machines

- Improved safety in the workplace

2. Workforce Upskilling for Modern Manufacturing

contemporary production desires professional people who can deal with the new generation. Upskilling method teaching personnel new skills. This enables them to work with clever machines and automatic systems. It also makes the workforce greater flexible and efficient.

Key benefits of upskilling:

- Better use of advanced machines

- better performance and productivity

- decreased errors and downtime

- stronger hassle-fixing skills

- progressed task delight and retention

3. Specialized Industry Tools

Sustainable production specializes in reducing waste and saving sources. It makes use of strength-green machines and substances. This helps guard the surroundings and lowers prices for businesses. Sustainability is becoming a key intention in present day factories

Benefits of specialized tools include:

- decreased power and water use

- much less waste and pollution

- Reduced errors and material waste

- Better safety for workers

- Easier maintenance and longer tool life

4. Sustainable Manufacturing Practices

Facts-driven choice making makes use of facts from machines and tactics to guide picks. It helps managers spot issues early and improve performance. With correct records, companies could make smarter and faster selections.

Benefits of sustainable practices include:

- improved production making plans

- reduced errors and downtime

- better resource control

- Improved brand image

- Compliance with environmental regulations

5. Data-Driven Decision Making

Data-driven decision making uses information from machines and processes to guide choices. It helps managers spot problems early and improve efficiency. With accurate data, companies can make smarter and faster decisions.

Benefits of data-driven decisions include:

- Improved production planning

- Reduced errors and downtime

- Better resource management

- Faster problem-solving

- Enhanced product quality

FAQs

1. What’s manufacturing performance?

It means producing extra merchandise faster, with much less waste and lower fees.

2. Why is automation critical in manufacturing?

Automation hastens production, reduces errors, and lowers hard work prices.

3. How does upskilling help people?

Upskilling teaches new competencies, improves productivity, and makes workers adaptable.

4. What are specialised industry tools?

These are tools designed for particular obligations to boom precision and performance.

5. Why use information-pushed choice making?

It facilitates managers making smarter, quicker choices and improves ordinary efficiency.

Final Words

production is converting fast. New gear, machines, and practices are making work faster and smarter. Businesses that adopt these developments can store time, lessen fees, and improve greatly.

Staying updated is crucial. Automation, upskilling, specialized equipment, sustainability, and data-pushed choices all help groups develop. expertise those developments can form the future of producing and keeping corporations aggressive.