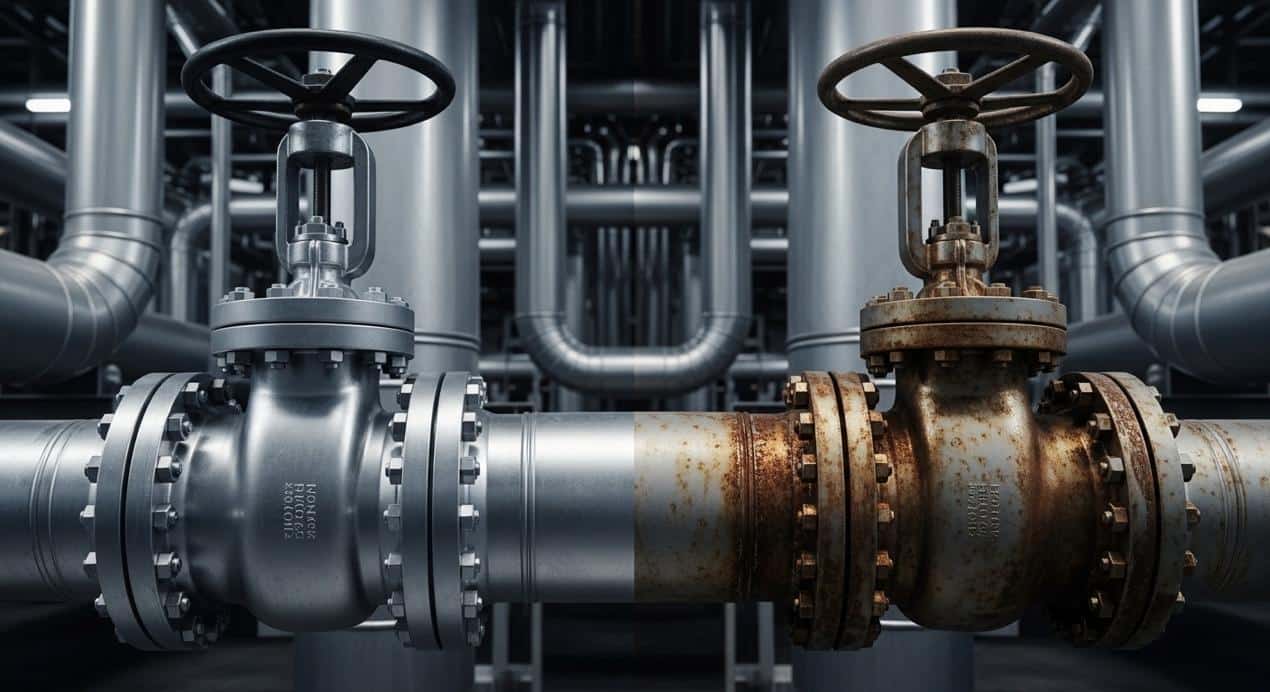

If you’ve spent any real time in a processing plant, you know the truth: the most significant failures often start with the smallest components. A multi-million dollar shutdown can originate from a single, poorly specified valve that succumbed to valve corrosion. I’ve seen it happen. Corrosion isn’t just a maintenance line item; it’s a relentless force of physics that actively seeks out the weakest points in your system. Ignoring it is not an option.

This article will share some hard-won insights into how corrosion actually behaves in the field and how to make robust engineering decisions to keep it in check.

The Real Mechanisms of Attack on Valves

Forget the generic image of orange rust. In industrial environments, corrosion is a far more complex and insidious process. For practical purposes, we generally face two primary drivers of metal degradation:

- Chemical Corrosion: This is a direct, brute-force attack. Think of highly concentrated acids or hot, dry gases literally dissolving the metal. It’s often predictable, but its speed can be alarming, especially at elevated temperatures which act as a powerful catalyst.

- Electrochemical Corrosion: This is the more common and cunning adversary in most fluid-handling systems. It requires an anode, a cathode, and an electrolyte (the process fluid itself) to create a “corrosion cell.” This is the mechanism behind the most dangerous forms of localized attack.

Understanding the specific form of corrosion is critical because the solution for one can be useless against another. Here are the culprits I see most often in the field:

| Corrosion Type | My Field Notes & Where to Look |

|---|---|

| Uniform Corrosion | This is the “best” of the worst types. It’s predictable, meaning we can often calculate a corrosion rate and plan for replacement. You’ll see it as an even thinning of the valve body or disc. The problem is, people get complacent and don’t inspect for it. |

| Galvanic Corrosion | A classic, preventable mistake. Bolting a carbon steel valve directly to stainless steel piping in a wet environment is just asking for the carbon steel to sacrifice itself. Check the junctions of dissimilar metals, especially around flanges and fasteners. |

| Crevice Corrosion | This one is sneaky. It hides in stagnant areas—under gaskets, in threaded connections, beneath deposits. The fluid in these crevices becomes highly corrosive, leading to intense, localized attack that you won’t see until it’s too late. |

| Pitting Corrosion | In my opinion, this is one of the most dangerous forms for valves for chemical service, especially in environments containing chlorides (like seawater or many chemical feedstocks). A tiny pit can penetrate a valve wall with surprising speed while the rest of the surface looks pristine. It’s a primary failure mode for ball valves and other quarter-turn designs where surface integrity is critical for sealing. |

| Intergranular Corrosion | This is a metallurgical issue, often caused by improper welding or heat treatment of stainless steels. It weakens the metal from the inside out, along its grain boundaries. The valve looks fine, but its structural integrity is gone. Catastrophic, brittle failure can occur under pressure. |

| Stress-Corrosion Cracking (SCC) | The trifecta for disaster: a susceptible material, a specific corrosive environment, and tensile stress (from pressure, installation, or residual manufacturing stress). It leads to fine cracks that can propagate rapidly, causing sudden, unexpected failure. A major concern in high-pressure steam, chloride, or sour service environments. |

| Erosion-Corrosion | When you have high-velocity flow, especially with suspended solids, it’s like sandblasting the protective oxide layer off the metal surface, allowing corrosion to attack the fresh metal underneath. Look for it in control valves, elbows, and any area where flow is turbulent. You’ll see it as grooves, gullies, or a directional pattern. |

The First and Most Important Defense: Material Selection

Everything else—coatings, inhibitors, cathodic protection—is a secondary measure. Your primary defense, the foundation of a reliable system, is choosing the right corrosion resistant valves from the start. This isn’t about picking the most expensive alloy; it’s about making a precise engineering match to the service conditions.

The selection process must be rigorous, considering all variables: chemical composition of the fluid (including trace contaminants), temperature range, pressure, flow velocity, and potential for upset conditions.

- Beyond Basic Stainless Steel: While 316L is a workhorse, it has its limits, particularly with chlorides. For seawater or brine applications, moving to a Duplex stainless steel is often a necessary step up. Duplex grades offer a superior combination of strength and resistance to both pitting and SCC.

- High-Stakes Environments: In truly aggressive media—think sulfuric acid, hydrofluoric acid, or high-temperature sour gas—you enter the realm of high-nickel and special alloys. Materials like Monel, Inconel, and Hastelloy C-276 are not interchangeable. Each is engineered for a specific set of corrosive challenges. Using them correctly requires deep metallurgical knowledge.

This is where the supply chain and manufacturing process become critically important. You can write the perfect material specification, but if the foundry doesn’t have precise control over the metallurgy, you won’t get the performance you paid for. This is why manufacturers who operate their own foundries, such as Neway Valve, have a significant, inherent advantage. They maintain end-to-end control over the entire process—from the chemical composition of the melt and the specifics of the heat treatment to the final non-destructive testing. This vertical integration is a powerful mitigator of material-related risk and ensures the alloy’s properties are consistent and verifiable.

Smart Design and Verified Quality: Beyond the Material Spec Sheet

Even the best material can fail if the valve isn’t designed and manufactured correctly. This is where adherence to stringent industry standards becomes more than a checkbox; it’s a proxy for quality and reliability.

- The Importance of Standards: When a valve is certified to NACE MR0175/ISO 15156 for sour service, it means the manufacturer has followed strict protocols for material selection, heat treatment, and hardness testing to prevent sulfide stress cracking. Similarly, an API 6D monogram on a pipeline valve isn’t just a label; it’s a guarantee of a rigorous quality assurance program. Final inspection and pressure testing, conforming to standards like API 598, is the last line of defense to ensure the valve’s integrity before it reaches the field.

- Engineering for Performance and Efficiency: Good engineering, however, goes beyond just meeting the standard; it involves leveraging it to create value. A prime example is how standards like API 603 are applied to stainless steel gate valves. Compared to the bulkier API 600 design, API 603 allows for a thinner wall section by capitalizing on the superior strength of stainless steel. Forward-thinking manufacturers, like Neway Valve certified with API 6D, use this to engineer valves that offer the exact same pressure-retaining capability and corrosion resistance but with significantly less weight. This isn’t just a minor tweak; it directly translates to lower material costs, easier installation, and reduced structural support requirements for piping systems. This is a perfect illustration of smart engineering in practice.

Final Thoughts

Viewing corrosion resistant valves as a capital expense is a flawed perspective. They are an investment in operational uptime, safety, and long-term asset integrity. The incremental cost of specifying the correct, high-integrity valve at the project stage is invariably dwarfed by the cost of a single shutdown, a leak, or a safety incident down the line.

The key is to work with manufacturers who demonstrate genuine technical expertise, not just salesmanship. Look for evidence of deep metallurgical knowledge, verifiable adherence to critical industry standards, and control over their manufacturing processes. Managing the long-term risk of valve corrosion begins and ends with making informed, engineering-led decisions.