For UK engineers and procurement specialists seeking reliable, high-performance small servo motor solutions, DMKE offers precision-engineered drives that meet the stringent demands of advanced automation, medical device, and robotic applications across the region. Our motors are designed to deliver consistent torque, accurate positioning, and quiet, energy-efficient operation, fully compliant with relevant UK and international standards. With a strong focus on custom OEM/ODM services, we provide flexible, collaborative engineering support—from rapid prototyping to stable bulk supply—ensuring your projects, from Cambridge tech startups to Midlands-based automation lines, benefit from robust performance, cost-effectiveness, and minimal downtime. Partner with DMKE for tailored servo solutions that combine innovation with the reliability required to keep your operations competitive and efficient.

Servo motors are widely known for their compact size and powerful capabilities. You need them to power your simple robots, AGVs, small medical appliances, or portable automation systems. A servo that delivers stable torque and accurate positioning despite its small size is what almost all modern automation appliances need.

Let’s be real, even when it is small in size, you want your servo motor to prove to be a reliable and long-term investment. You also want it to ensure the stability of operation over long hours. But this is exactly what most small servo motors fail to deliver.

With a large number of manufacturers claiming to manufacture the best small servo motors, inconsistent quality and limited customisation are huge problems for intelligent buyers. Slow engineering by most servo manufacturers often leads to delays in bulk projects. Getting multiple redesigns and facing downtimes because of motors’ unavailability adds more to your overall project cost.

This explains why working with a professional small servo motor manufacturer is essential. Professional manufacturers employ engineers with years of experience. These engineers are specialised in designing small, yet high-performance, servo solutions in bulk with zero compromise on quality.

Whether you want micro-level precision from your motor or longevity, or simply want something that can last long for basic operations, professionals have it all. Not only that, but you can also opt for OEM and ODM customizable solutions with such professionals.

Many times, clients often require specific torque values, speed readings, and a shaft design that suits their specific function. This is why a supplier who is able to provide the right kind of customisation and assistance is extremely important.

Below, we are going to walk you through the small servo options available at DMKE, our customisation steps, what makes them so special, and how you can get your solutions customised from us. So, read on.

Why Work With a Professional Small Servo Manufacturer?

Lately, there has been a rise in automation trends with more and more industries relying on servo solutions for their basic tasks. Hence, many manufacturers have stepped into the world of small servo manufacturing. However, it is important to note that not all of them can ensure the right kind of professionalism in their manufacturing process.

Many people underestimate the benefits of sourcing their items from professional manufacturers. However, this simple decision can dramatically enhance the overall reliability and performance of your setup.

The importance of right and professional manufacturing becomes extremely important in small servos. This is because their construction requires micro-level precision and careful material selection so they can deliver stable torque and precise speeds. Servos made by professionals are made to ensure accurate positioning in compact and confined spaces, with an ability to handle changing loads seamlessly.

Specialised manufacturers often have the required technical expertise and a team of professional engineers to design a flawless miniature motor. Their products make no compromise on their quality and delivery despite their small size.

Professional and trusted manufacturers have gained their reputation because of their strict quality control measures in the manufacturing and distribution processes. They use quality windings and advanced encoder calibration with their motors, along with other quality components that are made to last.

Most professional manufacturers often won’t make their motors available for customers unless each piece has passed quality tests of a certain kind. These include vibration testing, temperature endurance checks, and other checks to determine the motor’s precision. All such testing and careful selection of raw material for the construction ensure that the motor will perform consistently and will provide great ROI to its users.

A professional manufacturer can also help you with long-term projects. Most professional motor manufacturers can provide you with a consistent number of motorised units each month. This enables the smooth flow of large-scale industrial projects without inducing any downtime.

Another quality that sets most reliable and professional servo manufacturers apart from the unreliable ones is the post-sale experience provided by them. When you purchase a motor from professionals, you can easily reach out to them in case the motor stops working or if you experience a decline in its performance. Their motors mostly come with long-term warranties that vouch for their quality and performance.

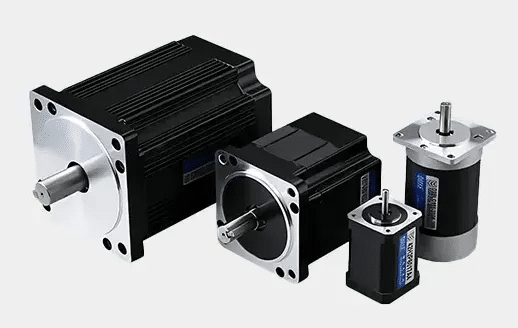

DMKE Small Servo Motor Solutions

At DMKE, we have mastered the art of small servo manufacturing. Our years of experience have led us to offer a vast range of small servo solutions that are designed particularly to meet your individual needs. Whether you want a solution for modern industries or simply want something that can power your commercial application, we have it all.

You can trust us for servo solutions that ensure high-speed motion, precise positioning, and smooth torque output with the ability to work in compact spaces. Our vast product lineup makes sure that each of our customers has something that can meet their needs.

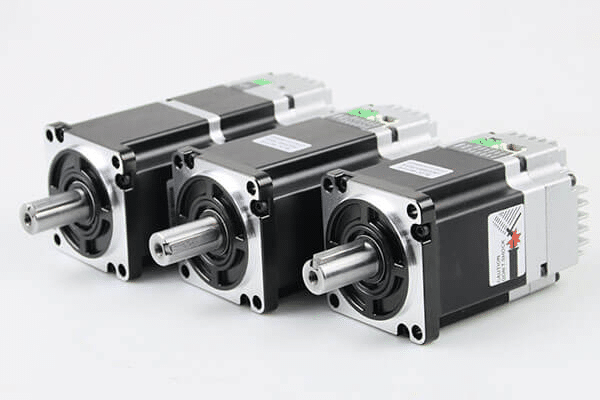

Among some of our most 0common servos are the DC Servos, Servo Planetary Gear Motors, Servo Worm Gear Motors, Hub Servos, and other BLDC servos.

Not only that, if you can’t find something that exactly meets your needs, you can always trust us for customised solutions. We can customise your motors for them to perform exactly how you want them to.

Our small AC servos deliver exceptional stability for long-hour working automation. Similarly, our DC servo solutions are best when you want a fast response with flexible automation control for dynamic equipment. Our BLDCs offer high torque and speed with long service life and power your robotic arms, AGVs, and medical devices like no other.

Whether you talk about vibration, noise, or glitching, our solutions have been designed to mitigate all these issues properly. For space-sensitive applications, you can always reach out to us to reconsider the existing solutions and upgrade them to their mini and micro versions. This helps us offer you exactly the kind of footprint that you want from your motors.

Not only that, our solutions are available in multiple voltage options with different encoder configurations, power ratings, and endless customisation possibilities. All you have to do is reach out to us so that we can get started with you. We are sure that we’ll have a solution for your project regardless of how big or small it is.

What Sets DMKE Small Servo Motors Apart?

At DMKE, all the small servo solutions that we engineer are made to deliver consistent, high-precision output, exactly as needed. Our solutions are often tailor-made to serve across a wide range of industrial functions.

There are several factors that set DMKE’s small servo motors apart from other lesser-known and unbranded solutions that come in portable sizes. Below are some of the qualities of our small servo motors that we take pride in:

- High Torque Density

Regardless of how small and portable they are, our servo solutions are designed to deliver a powerful torque output. They do so despite the changes in their external environment. The high torque density provided by our servos allows the equipment to achieve powerful and stable performance despite the increasing loads.

The best part about our small servo motors is that the torque remains unaffected regardless of how small the assembly is.

- Low Noise Operation

We understand that most portable servo solutions are often utilised for medical reasons and in other sensitive applications. This is why we ensure that all our solutions work with minimal vibration and hence create no noise. The quietness of working adds more value to their overall performance.

- Accurate Positioning And Fast Response

We utilise advanced control algorithms and rely on precise encoder feedback to ensure quick positioning with jitter-free movement. For applications that require micro movements and where precision cannot be compromised, our offerings are perfect. Not only that, but the DMKE small servo motors are also equipped with fast acceleration.

- Widespeed Control

Whether you want a motor that can perform low-speed precision tasks or want a solution for high-speed automation, DMKE won’t disappoint you. Our servos support a broad spectrum of RPM, and this flexibility helps engineers to customise their product’s behaviour to whatever is required from them.

- Compact Body with Lightweight Design

Not all small servo motors are necessarily light in weight. This is what we at DMKE have tried to tackle with our compact appliances that are constructed using very lightweight materials. Our motors are made to save space and ensure simple integration into even the lightest of appliances.

- Energy Efficiency

All our products are made in a way to minimise power consumption, thus making a little difference to your electricity bills. This energy efficiency with maximum power output makes DMKE offerings worth every penny.

Custom OEM/ODM Services

With DMKE, you can get your customised small servo motors tailored exactly how you need. We offer a wide range of OEM customisation, so you can get a motor with your desired voltage, speed, torque, and motor dimensions.

Not only that, but we also provide specialised ODM solutions to businesses developing new products and requiring highly specialised servo motors. Our ODM solutions can help experts avail our ODM solutions to get support with initial motor conceptualisation to final production and everything else in between.

You can get your desired housing structure and control algorithms, as well as motor and driver combinations, as and how you require.

Key Advantages of Choosing DMKE

We understand that there are many reliable small servo motor manufacturers out there. However, there are several reasons why we persuade our potential clients to pursue their motor solution manufacturing with DMKE.

When you choose DMKE to manufacture your custom servo solutions, you are partnering with somebody who has strong technical knowledge. Our engineers are able to translate their expertise into impeccable production capabilities.

Our R&D and engineering team know what they do, and are capable of utilising their deep experience in microprecision motor design. This helps our clients overcome motor solution challenges like no other. Not only that, but we also ensure to extend technical support throughout, from designing to installation and utilisation.

Another major benefit of choosing DMKE is that you get to experience cost-effectiveness like never before. Despite using high-quality products, components, and efficient manufacturing processes under the strict supervision of expert engineers, we make sure to competitively price all our offerings. This helps you get something that is in your budget without any compromise.

Another reason is that DMKE benefits its bulk motor buyers with a stable supply chain and global shipping. We ensure that all our customers receive consistent delivery of small and big servos during their desired time periods. This makes us a trusted name for long-term partnerships.

DMKE’s Customisation & Production Process

Having an understanding of our small servo motor customisation and production process can help you see how our highly efficient workflow meets your exact needs from a motor. Each and every step of our process is designed after numerous tests and consultations with pro-engineers who know their job well. Below are the steps with which most of our custom motors are produced:

Step 1. Analysis Of Requirements And Technical Consultation

Everything starts with a detailed discussion of our client’s requirements. Our team of expert engineers reviews the torque, speed, range, size, and other dimensional demands and limitations, along with your expectations for the motor.

We also carry out a detailed analysis of the operating environment in which the motor will operate. This detailed technical consultation ensures that we completely understand the real-world challenges that the motor can face later. Not just that, but this discussion also helps us recommend a perfect motorised solution for your needs.

Step 2. Engineering Design And Performance Evaluation

Once we have decided on a motor design based on the above discussion, our engineers begin working on the prototype of your servo motor. This involves customising multiple mechanical components and appropriating the encoders along with adjusting the winding methods and more. Sometimes we use 3D modelling and simulation tools to test the performance virtually before we finalise the production.

Step 3. Prototype Testing

Once the motor prototype is developed and designed, we allow our customers to test its working to verify whether or not the motor fulfils their requirements accurately. Our engineers stay with you during this entire testing to note down any discrepancies that may need adjustment at a later stage.

Step 4. Finalisation And Mass Production Followed By QA Testing

Once the client validates the prototype and gives us a go-ahead for production, we start utilising our strict quality control standards to produce your required motors in bulk. Each and every motor that is produced in this process undergoes a rigorous 8-step QA testing to make sure that it fulfils the expectations set for it.

Industries & Applications We Serve

As already stated, small servo motors built by DMKE are made in a way to ensure professional utilisation across various industries. Some of the most common industries and applications where DMKE servo motors are a common sight include the following:

- Our motors have been powering industrial robotic lines and automation lines since forever.

- Most of the AGVs and AMRs that navigate narrow paths with ease are made by us.

- We have developer many motorised setups to power Material Handling Equipment in large-scale industries.

- Our small motors with low-noise capabilities have been powering CNC Machinery, Routers and Precision Equipment across the globe.

- We are also the name behind several packaging materials and conveyor belts.

- Our experts have successfully crafted medical and laboratory instruments, customer electronics and educational robotics, machines for hobbyists and college laboratories, and packaging and printing machines.

Connect With DMKE To Get Custom Small Servo Motors

Choosing the right small servo motor manufacturer could get difficult, but not when you have DMKE to serve you. Our custom solutions are here to help you make all the difference. We combine precision engineering with quality control and rigorous post-production checks. This is done to make sure you get the perfect motor model available for your needs.

Our advanced research and development, as well as customisation capabilities, help us deliver small servo motors tailored to your exact needs with all your industrial and commercial requirements. Whether you want high torque density motors with smooth positioning or small motors that make no noise while working at full speed, we have it all.

Our flexible OEM and ODM services can help with low minimum order quantities and rapid prototyping. DMKE is one of the best motor manufacturers and suppliers in the market. Our 25 years of experience help us craft motors that promise precision, power, and performance like none other.

Are you ready to elevate your project with high-performance small servo motors and other custom motor solutions? Visit our website or contact us today to get expert guidance, support, and motor prototyping tailored to your exact needs. Trusting DMKE will help you start your custom motor solution journey with reliability and innovation guaranteed.