In today’s highly-competitive and fast-paced business landscape, warehouse automation has become increasingly important for companies looking to optimize their operations and gain a competitive advantage. Two key solutions that have emerged with technological advancements include automated warehouse solutions and semi-automated warehouses. Both solutions aim to enhance the efficiency and productivity of warehousing businesses. Read on to learn about their key components, differences, product recommendations, etc.

Automated Warehouse Solution

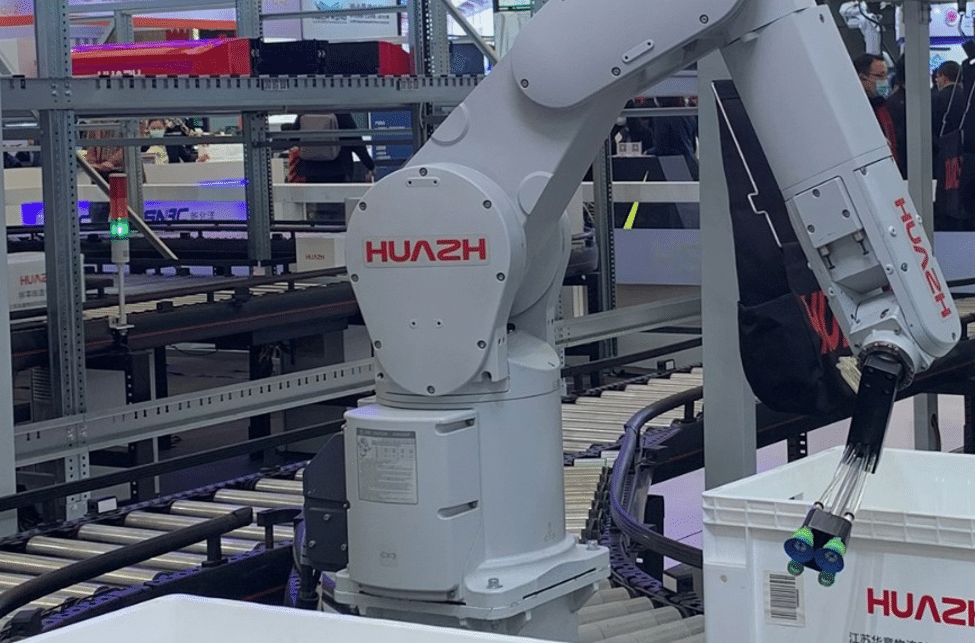

It is a comprehensive system that uses advanced technologies to automate and streamline various warehousing processes. It integrates sophisticated software, artificial intelligence, and robotics to handle material handling, order fulfillment, and inventory management.

The high-performance dismantling and picking solution in an automated warehouse is a goods-to-person system. This system efficiently supplies materials and offers a well-designed site structure, ensuring ergonomic conditions. A fast and intelligent approach to material handling fulfills customer orders by bringing the goods directly to the operators instead of the traditional method of operators going to the goods.

Semi-Automated Warehouse Solution

It combines the elements of automation with human labor to improve the efficiency of warehouse operations. It involves using technology to augment human capabilities, reduce errors, and improve productivity while relying on manual input for specific tasks. The key components of a semi-automated warehouse solution include the following:

1. Shuttle ASRS

Shuttle ASRS is an automated storage and retrieval system that uses shuttle vehicles to efficiently store and retrieve goods in warehouses. It maximizes storage capacity and streamlines inventory management.

2. Picking Station System

Utilizing a picking station system offers a cutting-edge approach to enhance the efficiency of the split-picking process. By allowing robots to perform repetitive picking tasks over an extended period, the system conserves human resources, greatly enhances picking speed, and guarantees precision. Considering the rising costs associated with labor, it is evident that goods-to-robot sorters possess distinct benefits in this regard.

3. Automated Conveyor Systems

Automated conveyor systems automate the movement of items within a warehouse, facilitating the flow of products from one point to another and minimizing manual handling. These systems can be integrated with other automation technologies, e.g., sorting machines, barcode scanners, etc., to streamline operations.

4. Order Processing System (OPS)

The order processing system (OPS) is the central hub and control center for the goods-to-person order fulfillment system. Through effective coordination with AS/RS shuttle systems, conveyor systems, goods-to-person picking stations, and other components, OPS enables orders from various businesses, as directed by the Warehouse Management System (WMS). This ensures a streamlined, precise, and orderly execution of tasks, resulting in improved operational efficiency and elevated management standards within the internal logistics framework.

Differences Between Automated and Semi-Automated Warehouse Solutions

While both automated warehouse management systems and semi-automated warehouse solutions have similarities, there are many key differences between them. These include the following:

1. Level of Automation

A fully automated warehouse relies more heavily on advanced technologies and robotics to perform operations automatically. Semi-automated solutions, on the other hand, involve a greater degree of human involvement alongside automation. The overall level of automation is lower than automated warehouse solutions.

2. Accuracy and Error Reduction

Automated warehouse solutions tend to offer higher accuracy levels and greater error reduction because there is minimal human intervention. The margin of human error is higher when it comes to semi-automated warehouse solutions.

3. Costs and Return on Investment (ROI)

An automated warehouse management system typically requires a higher upfront investment than a semi-automated warehouse solution, but it also offers greater long-term cost savings thanks to increased throughput, reduced labor costs, and improved efficiency.

4. Scalability and Adaptability

Automated warehouse systems are generally more adaptable and scalable to changing business needs than semi-automated warehouse systems. They can be easily expanded and reconfigured to accommodate changes in product mix and increased volumes.

5. Handling of SKU Variety

Automated warehouse solutions specialize in handling a wide range of SKUs because they can efficiently store and manage diverse product sizes and types. Semi-automated solutions may have limitations in managing a large SKU variety.

The Most Reliable Warehouse Automation Solution: SLS400 Series From HWA

The SLS400 Series from HWA is a high-speed robotic shuttle system designed to revolutionize warehouse automation. It offers intelligent software and advanced robotics hardware to enhance operational efficiency and productivity. Key features and advantages of the SLS400 Series include:

- High-speed robotic shuttle system for fast, efficient goods transportation

- High storage density

- Flexible system operation with dynamic adjustment capability

- Compatible with a wide range of goods sizes

- Flexible size confirmation and barcode recognition system

- Large order handling capacity and convenient scalability

- Lower power consumption

Conclusion

Warehouse automation solutions, whether automated or semi-automated, can significantly improve operational efficiency and productivity. When choosing a warehouse automation solution, it is important to choose a reliable supplier. HWA, a seasoned warehouse automation company, offers reliable solutions with a commitment to quality and industry experience. HWA holds the distinction of being the pioneer among manufacturers in China, as they were the first to obtain a patent for the shuttle system and successfully deploy the goods-to-person system. To explore more about their warehouse automation products, please visit HWA’s official website.