In the realm of hygiene, safety, and efficiency, a technology is making waves, revolutionizing how the food industry maintains cleanliness. Laser cleaning, a technique as intriguing as it sounds, uses laser-induced ablation to remove contaminants and impurities from surfaces, including machinery and tools used in food processing. This innovative approach has the potential to be the game-changer in the food industry, rendering obsolete the traditional cleaning methods that have long been in practice.

What is Laser Cleaning?

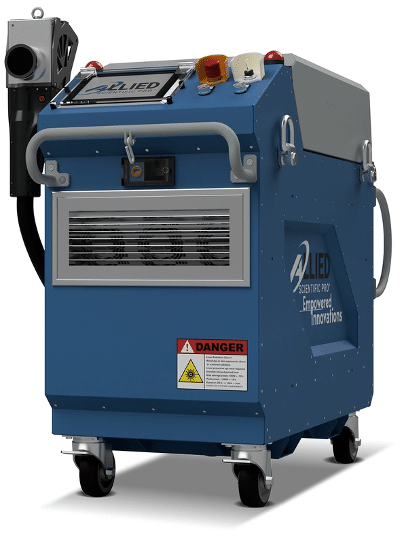

Laser cleaning, often referred to as laser ablation, is a process that harnesses the power of laser technology to effectively and efficiently clean surfaces. A laser cleaning system employs laser pulses to ablate, or remove, surface contaminants or materials. This high-precision process has gained traction across various industries, most notably in the food sector, where hygiene is paramount.

As laser cleaning doesn’t rely on chemical substances or abrasive materials, it offers an environmentally-friendly, non-contact, and residue-free alternative to traditional cleaning methods. This technique has the potential to elevate food industry standards, promising numerous advantages over its conventional counterparts.

Laser Cleaning: Advantages Unveiled

With its unique and efficient mechanism, laser cleaning brings several benefits to the food industry, where the cleanliness of machinery and equipment is of utmost importance.

Increased Efficiency

Laser cleaning operates at a rapid pace. The method can clean larger surfaces in a shorter timeframe compared to traditional cleaning techniques. This increased efficiency allows for minimized downtime and enhanced productivity in food processing plants.

Enhanced Precision

The precision of laser cleaning is unparalleled. With the capability to target minute areas, the method ensures comprehensive cleaning, even in hard-to-reach corners and crevices of complex machinery. This leads to improved maintenance and longevity of equipment.

Environmental Friendliness

As a chemical-free process, laser cleaning mitigates the risks of harmful substance disposal. This environmental advantage is an essential aspect for an industry under scrutiny for its environmental impact.

Improved Food Safety

By eliminating potential contaminants on the machinery used in food production, laser cleaning enhances food safety standards. It reduces the risk of cross-contamination, contributing to the overall quality and safety of food products.

Implementing Laser Cleaning in the Food Industry

Integrating laser cleaning technology into existing food processing practices is a step-by-step process. Firstly, it involves understanding the specific cleaning requirements, whether it’s the removal of organic residue or inorganic substances. The correct laser type, pulse duration, and power must be chosen based on these requirements.

Next, the laser system is set up and configured, ensuring all safety measures are in place. Finally, it’s a matter of scheduling regular laser cleaning routines to maintain a high level of cleanliness and hygiene across all food processing equipment.

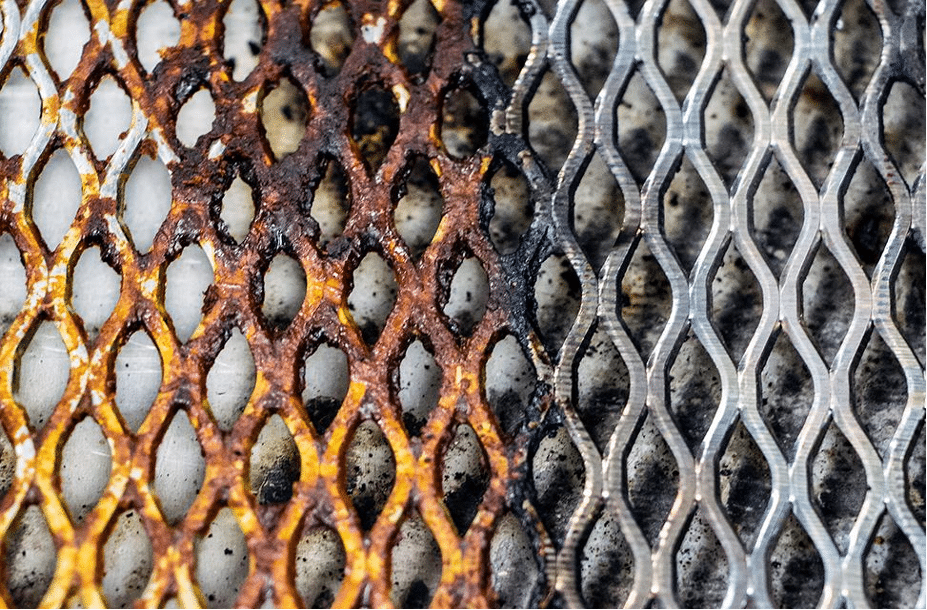

Laser Cleaning vs. Traditional Cleaning Methods

Understanding the transformative potential of laser cleaning in the food industry requires a comparative look at traditional cleaning methods. Standard cleaning techniques, while effective, have their share of limitations that laser cleaning adroitly overcomes.

Time-Consuming and Less Efficient

Traditional cleaning methods in the food industry, like scrubbing and washing, are usually labor-intensive and time-consuming. The intricate components of food processing equipment can be challenging to clean effectively, leading to inefficient operations. Conversely, laser cleaning’s precision and speed ensure a thorough and fast cleaning process, leading to reduced downtime in production.

Use of Chemicals

Chemical cleaning, commonly used to remove stubborn organic residues, involves the use of detergents or solvents. These chemicals can pose risks of residue left on equipment, potentially contaminating food. Laser cleaning sidesteps this issue by offering a residue-free and chemical-free cleaning solution, eliminating the risk of chemical contamination.

Wear and Tear

Abrasive cleaning methods can cause damage to the surfaces of equipment, leading to a shorter lifespan. The non-contact nature of laser cleaning ensures there’s no physical wear and tear on the machinery, contributing to prolonged equipment life.

Real-world Applications of Laser Cleaning in the Food Industry

The application of laser cleaning in the food industry is wide and varied, extending from bakery equipment to dairy processing machinery and beyond.

Bakery Equipment Cleaning

Bakery equipment often encounters the buildup of carbon deposits and baked-on residues on the conveyor oven. These stubborn impurities can be efficiently removed with laser cleaning, ensuring a clean and safe baking environment.

Dairy Processing Equipment Cleaning

In dairy processing, it’s crucial to maintain the highest hygiene standards to prevent bacterial growth. Laser cleaning, with its precision and efficiency, provides an effective solution for cleaning intricate parts of dairy processing equipment.

Beverage Industry Applications

For beverage production facilities, cleanliness of machinery is of paramount importance. Laser cleaning helps maintain the hygiene standards in these facilities, from cleaning residue on bottling lines to maintaining the cleanliness of brewing equipment.

The Role of Research in Laser Cleaning Technology

Research and development play an integral role in the progress of laser cleaning technology. Scientists and engineers are constantly working on improving the efficiency and safety of this cleaning method. They’re exploring new types of lasers, refining the techniques to make them more effective and affordable, and widening the range of applications in the food industry.

For instance, the Fraunhofer Institute for Laser Technology ILT has been conducting extensive research on laser cleaning processes, contributing significantly to the advancements in this field. Through such dedicated research efforts, the potential of laser cleaning technology continues to expand, opening new horizons for hygiene and cleanliness in the food industry.

The Future of Laser Cleaning in the Food Industry

As the food industry continues to prioritize safety and efficiency, laser cleaning is set to play an increasingly crucial role. The technology’s ability to clean thoroughly without chemicals, coupled with its efficiency and precision, make it a highly attractive solution for future food processing methods.

However, challenges exist in the form of initial setup costs and the need for trained personnel to operate the laser cleaning equipment. Nevertheless, as the technology continues to evolve and become more accessible, the adoption of laser cleaning in the food industry is anticipated to grow exponentially.

Final Thoughts

From the above exploration, it’s evident that laser cleaning offers compelling advantages to the food industry. This innovative method, backed by continuous research and development, paves the way for a new era of cleanliness in food production. Laser cleaning’s efficiency, precision, and environmental friendliness make it a promising alternative to traditional cleaning techniques. While challenges like high initial setup costs and need for trained operators exist, the benefits offered by this technology far outweigh the hurdles.

As we move into the future, the adoption of laser cleaning in the food industry is expected to become increasingly widespread, setting new benchmarks for hygiene and safety. With cleaner machinery comes safer food, and that is a transformation worth embracing.