Robotic automation is the new trend in most manufacturing companies. Robots have helped ease manufacturing operations to the extent of them becoming more trusted than employees’ capabilities. Even though most industries lack the experts or skilled individuals to operate the robots, they still consider investing in robots because of the immense benefits that accrue from manufacturing automation.

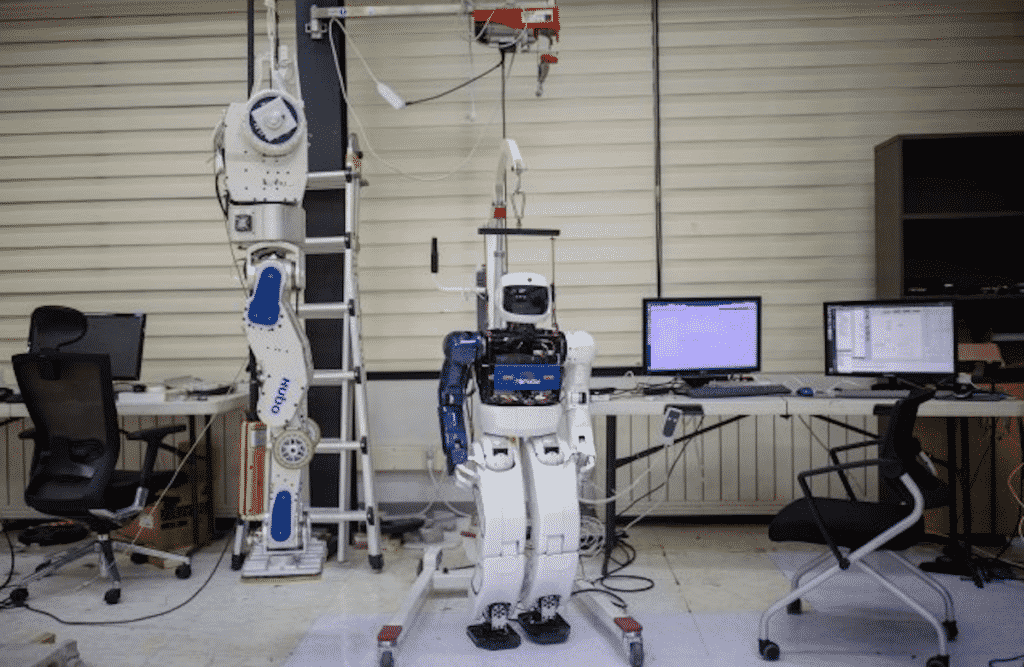

Manufacturing automation involves mechanizing various manufacturing processes, such that it is the machines, otherwise known as robots that perform the processing tasks. There are two main categories of robots; the traditional industrial robots and the collaborative robots. The main difference between the two types of robots is that the regular industrial robot is autonomous, whereas the collaborative robot is not fully autonomous and works side-by-se with industry employees.

The following is an outline of the significant advantages of manufacturing automation.

Advantages of Robots to Business

1. Employee Safety

Industrial manufacturing involves very dangerous processes that expose employees to harm and injury. For instance, the lifting tasks, loading and unloading of heavy product,s and equipment can be very detrimental to your health. With time, your back, waist, and joints begin to ache, and you can only have the heavy industrial jobs to blame.

Moreover, exposure to fumes, dust and various chemical sprays is risky to your health. Hence, this calls for manufacturing automation, where there is the introduction of robots to take over such heavy and dangerous tasks. It is of great benefit to both the company and its employees. The costs related to compensation due to injuries are eliminated.

2. Reduced Wastage

Regular processing without the use of robots involves too much wastage. The robots aid in reducing such industrial wastage. The robots are programmed to perform their tasks, and because of their high level of precision and exactness, material wastages are entirely reduced or eliminated.

Moreover, wastes resulting from dissimilar or damaged goods are eliminated as the robots perform exactly as instructed. The goods come out as programmed in the robot’s system. Moreover, robots produce quality goods. That means for every sale made; there are no returns occasioned by the company, since the goods provide total satisfaction to the customers. Hence, wastes through sales return are reduced, and the company is able to maintain great company-customer relationships.

3. Increased Return on Investment (ROI)

Manufacturing automation results in increased profitability for the company. Productivity increases when the robots take over the heavy and dangerous tasks and free the employees to handle other tasks that are intent on increasing a company’s productivity.

Moreover, with robots, there is increased production in terms of capacity, plus there is a reduction in material wastage. All these contribute to increased profitability, and hence heightened ROI.

4. Consistency in Production

Manufacturing automation through the use of robots enables consistent production. Machines can work non-stop, unlike humans who have to take breaks and go on leave. Therefore, in the event that a company receives an order for some products, it can be sure that it will meet the order. Additionally, machines do not get sick like the way humans do. Hence, there is no interruption of production.

5. Increased Productivity

The productivity of a company is certain to increase with the presence of robots doing most of the work. Robots can operate 24/7 without tiring. Moreover, the employees are free to focus on other productive areas of the company. That way, the company’s productivity shoots, and the company can stay competitive in the industry.

Conclusion

The above-mentioned advantages are just but a few of the advantages of manufacturing automation. We can go on and on about the benefits that accrue from automating industrial processes. However, it is quite evident that robots have had an exceedingly significant positive impact on industries. Going forward, many industries are embracing robotic automation. The robots will continue to revolutionize industries in more extra ordinary ways than we can fathom.