Computer Numerical Control (CNC) is a programmable algorithm, which gives a machine a set of precise instructions to carry out certain machining processes like drilling, milling, etc. The code signifies the process of adding, removing or drilling material, based on their required design.

A CNC interacts with the machine via a compatible computer and software. CNC codes are numerical, so the software converts the input into Cartesian coordinates, which allows the machine to function in different planes and degrees of freedom. This gives machines the ability to work with precision, without any error.

Today, CNC machining has become a lucrative method to perform various machining operations on raw materials to produce an end product. A CNC machine can transform any given material into a specific product using two main methods: by adding material (additive process) or by removing the material (subtractive process).

3D printers and CNC milling machines are a few popular examples of additive and subtractive CNC operations, respectively.

What is a CNC Milling Machine?

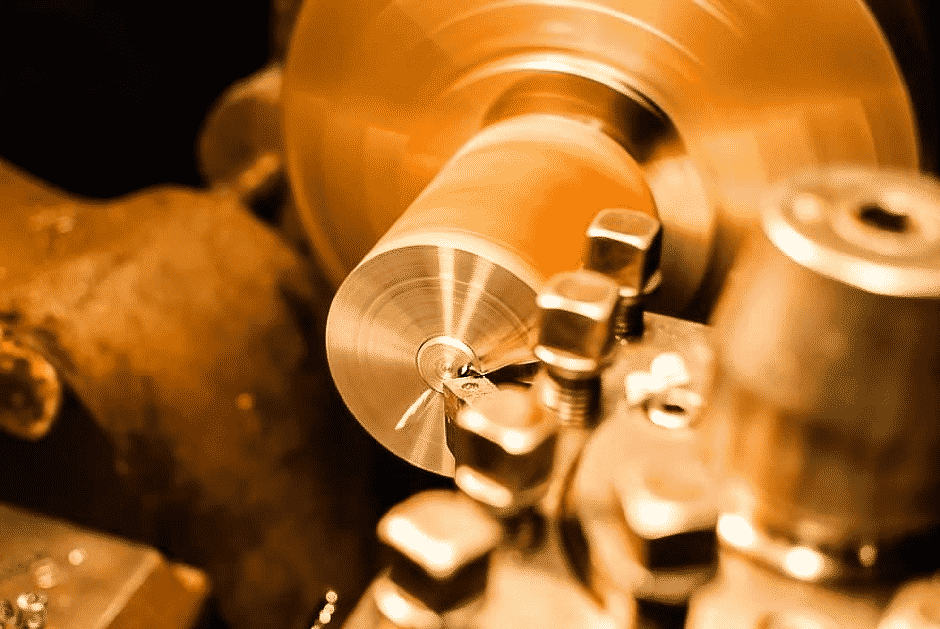

A CNC milling machine is a heavy-duty machine tool that uses computerized controls to perform milling processes on raw material. The machine employs a rotating multi-point cutting tool which gradually removes material from a work piece with the utmost precision.

CNC milling is popularly utilized in manufacturing and designing factories across the world to machine a diverse range of materials like metal, plastic, glass and wood.

Types of CNC Milling Machines

Though milling seems a lot like drilling, both these operations are very distinct from one another. Drilling usually cuts along one angle and one axis, whereas milling can perform the same operation at multiple angles and 2-5 axes. Below are the different types of CNC milling machines:

- 2-axis CNC milling machines: These milling machines can cut holes and different slots on two specific axes (x-axis and z-axis), so the machine will only cut vertically and horizontally.

- 3-axis CNC milling machines: These are similar to the 2-axes machines, but have the additional freedom to cut along the y-axis as well. One can cut from any direction.

- 4-axis CNC milling machines: These machines are a little advanced as they can perform operations while rotating on the x-axis.

- 5-axis CNC milling machines: These machines can rotate along the x and y axes, hence providing the most freedom in a milling operation.

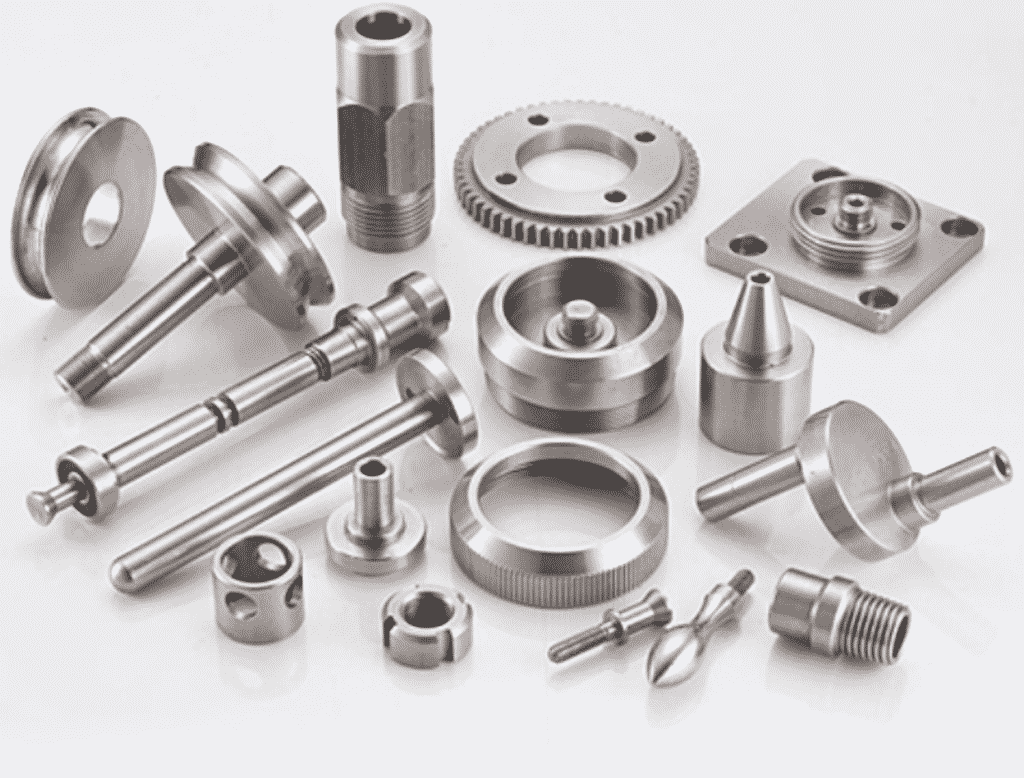

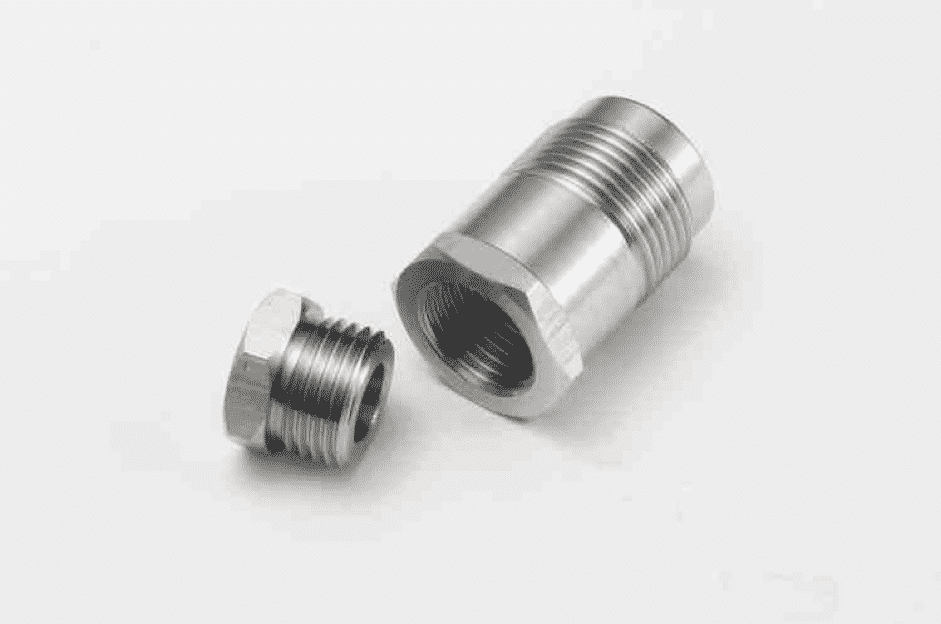

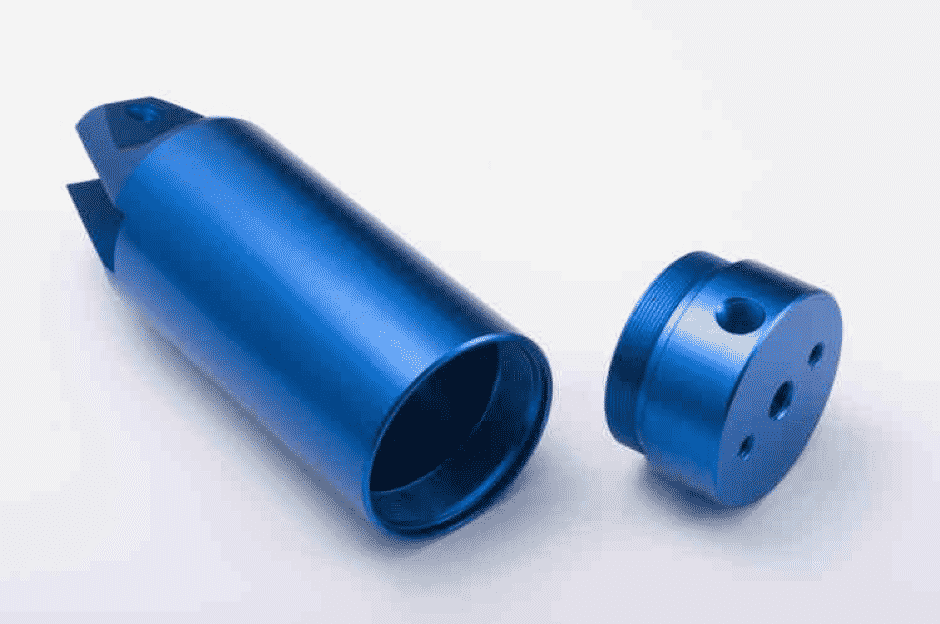

CNC Milling Parts

Frame

This CNC milling part provides rigidity to the machine to resist extra cutting forces. It is the backbone of the whole structure and generally comes attached to the base with a detachable column.

Table

The table is where the work piece is held firmly during the milling process. Milling machines use T-Slots to attach a machine-vice which holds the work piece, but there are CNC milling parts like fixture plates that can be used as well.

Spindle

The spindle is one of the most important parts of the milling operation. It has a rotating assembly where the tool holder is attached.

CNC Controller

The CNC controller is the brains of the machine. It consists of an electronic mechanism that drives the axis motors to move along a certain path. CNC controllers accept G-Code and also manual inputs from the control panel, converting codes to control the servo motors.

Conclusion

CNC milling machines are state of the art pieces of technology. It is hard to get a hold of legitimate CNC parts once a malfunction happens.

Bruico is one of the leading CNC milling parts and machine manufacturers in the Asian Continent. With specialization in various electrical, mechanical and other CNC machining parts, Bruico has been providing the medical, military and aviation industry with solutions for more than a decade.