Supply chain management and logistics are the lifelines of modern businesses, ensuring the smooth flow of goods from production to consumption. In today’s fast-paced and increasingly interconnected global marketplace, companies face mounting pressure to optimize their supply chain operations for efficiency, accuracy, and transparency.

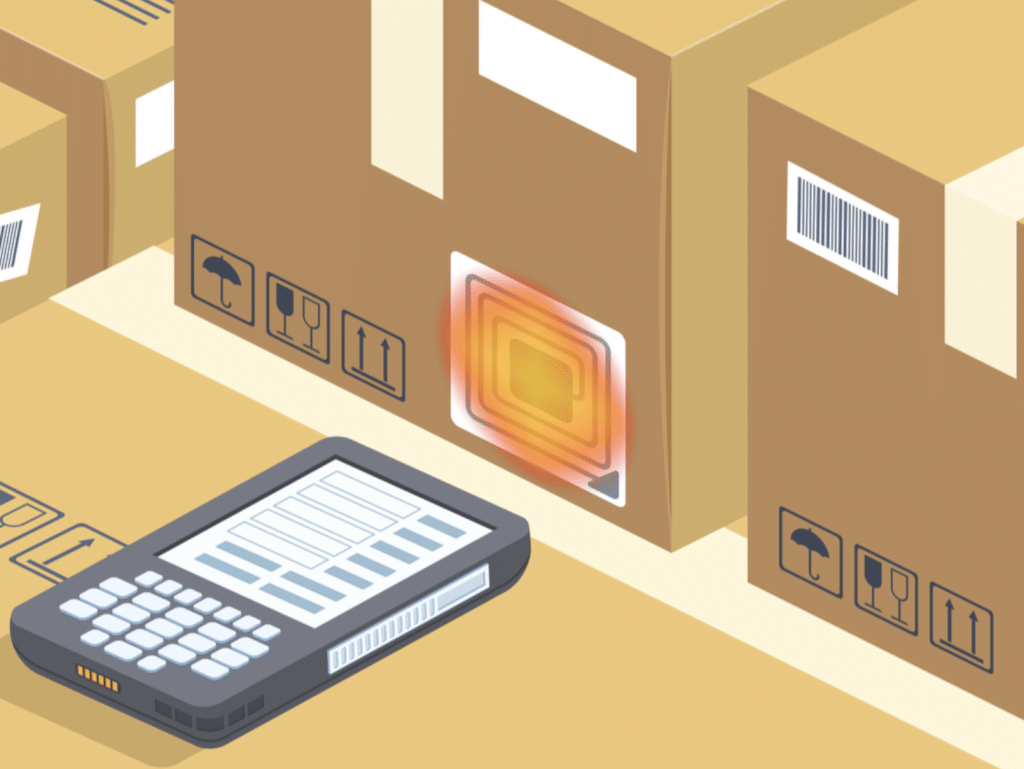

Amidst these challenges, Radio Frequency Identification (RFID) technology has emerged as a powerful tool for revolutionizing supply chain management and logistics. RFID offers a digital tracking system that uses radio waves to transmit data from tags attached to objects, providing real-time visibility and insights into the movement of goods throughout the supply chain.

In this blog, we will explore the myriad benefits of RFID in logistics and supply chain management. From enhancing inventory visibility to reducing operational costs, RFID promises to transform traditional supply chain practices into agile and responsive operations. Let’s delve deeper into RFID’s seven key advantages, unlocking new business possibilities in today’s competitive world.

1. Enhanced Inventory Visibility

RFID technology offers unparalleled visibility into inventory levels, enabling businesses to track the exact location and status of goods in real time. Unlike traditional barcode systems that require line-of-sight scanning, RFID tags can be read remotely and simultaneously, providing comprehensive visibility across the entire supply chain.

With RFID, businesses can monitor inventory movements from receiving goods at the warehouse to their final destination. This heightened visibility allows for better inventory management, as companies can quickly identify discrepancies, minimize stockouts, and optimize inventory levels to meet demand fluctuations.

Moreover, RFID enables automated inventory tracking, reducing the need for manual intervention and minimizing the risk of human error. By automatically capturing data as goods pass through RFID readers, businesses can ensure accurate and up-to-date inventory records, improving operational efficiency and customer satisfaction.

2. Improved Inventory Accuracy

RFID technology significantly enhances inventory accuracy by eliminating the need for manual counting and reducing errors associated with traditional inventory management methods. With RFID tags attached to individual items or pallets, businesses can accurately track inventory levels in real-time, ensuring that stock counts are always up-to-date and accurate.

Unlike barcodes, which must be scanned one at a time, RFID tags can be read simultaneously and from a distance, allowing for rapid and efficient inventory counting. This increased speed and accuracy enable businesses to conduct more frequent inventory audits without disrupting operations, leading to higher inventory accuracy and reliability.

By minimizing errors and discrepancies in inventory records, RFID helps businesses reduce the risk of stockouts, overstocking, and shrinkage, ultimately improving operational efficiency and profitability. With improved inventory accuracy, businesses can make more informed decisions about procurement, replenishment, and order fulfillment, driving better overall supply chain performance.

3. Streamlined Operations

RFID technology streamlines supply chain operations by automating manual processes, reducing labor-intensive tasks, and improving workflow efficiency. By integrating RFID systems into various supply chain stages, businesses can optimize key processes such as receiving, picking, packing, and shipping, resulting in faster turnaround times and reduced lead times.

One of the primary benefits of RFID is its ability to enable “hands-free” inventory management, allowing goods to be automatically tracked and monitored as they move through the supply chain. This automation eliminates the need for manual data entry and reduces the risk of errors, resulting in smoother and more streamlined operations.

Additionally, RFID facilitates better asset utilization by providing insights into the location and status of assets in real time. By optimizing asset tracking and utilization, businesses can minimize idle time, reduce costs, and improve resource allocation, leading to greater operational efficiency and productivity.

4. Increased Supply Chain Visibility

RFID technology enhances supply chain visibility by providing real-time insights into the movement and status of goods across the entire supply chain network. Unlike traditional tracking methods, which offer limited visibility and rely on manual data entry, RFID enables businesses to track goods automatically and accurately throughout their journey.

By deploying RFID tags at key points in the supply chain, such as manufacturing facilities, warehouses, distribution centers, and retail stores, businesses can capture valuable data on the location, condition, and history of goods in transit. This increased visibility enables businesses to identify potential bottlenecks, optimize routing, and proactively address issues before they escalate.

Moreover, RFID enables businesses to track and trace products more precisely, facilitating compliance with regulatory requirements and quality standards. RFID helps businesses ensure product safety, authenticity, and integrity throughout the supply chain by providing a complete audit trail of product movements and transactions.

5. Enhanced Product Traceability

Product traceability is essential for ensuring compliance with regulatory requirements, product quality, and consumer safety. RFID technology enhances product traceability by providing detailed information on the origin, journey, and handling of products throughout the supply chain.

By attaching RFID tags to products, businesses can capture real-time data on manufacturing, shipping, and handling activities. Enhanced product traceability enables businesses to track and trace products accurately, identify quality issues, and implement timely recalls if necessary.

With RFID technology, businesses can improve product safety, prevent counterfeiting, and protect brand reputation. Enhanced product traceability enables businesses to meet regulatory requirements, maintain consumer trust, and differentiate themselves in the market.

6. Theft Prevention and Loss Reduction

Theft and loss of inventory can have significant financial implications for businesses, reducing profitability and increasing operational costs. RFID technology helps prevent theft and reduce losses by enhancing security measures and improving inventory management practices.

By tagging high-value items with RFID tags, businesses can track their movement in real-time and detect unauthorized removal or tampering. RFID-enabled alerts and alarms enable businesses to respond quickly to security threats and prevent theft before it occurs.

Moreover, RFID technology helps reduce losses associated with inventory shrinkage, errors, and misplacements. By providing accurate and up-to-date inventory data, businesses can identify discrepancies, investigate root causes, and implement corrective actions to minimize losses.

With RFID technology, businesses can improve inventory accuracy, enhance security measures, and reduce the risk of theft and loss. Theft prevention and loss reduction measures enable businesses to protect their assets, maintain profitability, and sustain long-term growth.

7. Cost Savings

Cost management is critical for businesses to maintain profitability and competitiveness in today’s market. RFID technology helps businesses achieve cost savings by improving operational efficiency, reducing labor costs, and optimizing resource utilization.

By automating manual processes and streamlining operations, RFID technology helps businesses minimize labor costs associated with inventory management, order processing, and asset tracking. RFID-enabled automation reduces the need for manual intervention, freeing up resources to focus on higher-value tasks.

Moreover, RFID technology helps optimize inventory management practices, reducing holding costs, stockouts, and overstocking. By providing accurate and up-to-date inventory data, businesses can minimize excess inventory, improve inventory turnover rates, and optimize working capital allocation.

Conclusion

RFID technology offers many benefits for supply chain management and logistics, including enhanced inventory visibility, improved inventory accuracy, streamlined operations, increased supply chain visibility, enhanced product traceability, theft prevention and loss reduction, and cost savings.

By leveraging RFID technology, businesses can achieve greater efficiency, accuracy, and transparency in their supply chain operations. Enhanced visibility and traceability enable businesses to make better-informed decisions, optimize inventory management practices, and improve overall operational performance. So, if you want to implement RFID in the logisticsmarket, contact professionals now!