A digital data logger is a portable, programmable electronic device that monitors, records, and stores data related to various types of environmental conditions. These devices utilize internal sensors or external probes to measure temperature, humidity, pressure, or voltage. Some data loggers can track more than one type of condition. These devices are used in any industry that has strict compliance guidelines to provide information through collected data to verify that the required conditions have been met and maintained. In this article, we will look at four industries that rely on the accuracy of digital data loggers.

Pharmaceutical

To meet the standards set by the Food and Drug Administration (FDA) and World Health Organization (WHO), digital data loggers are regularly used to monitor the environmental conditions in laboratory settings and cold storage facilities. The temperature and humidity of these places are critical during the manufacture, storage, and transport of vaccines and medications, some of which require storage in extremely cold temperatures to prevent spoilage. Digital data loggers are portable enough to ride along with sensitive assets as they travel through the cold chain ensuring that they have not been subjected to temperatures that fall out of the safety zones ordered by compliance standards. Even a slight variation in conditions can affect the effectiveness of some medications and other pharmaceuticals. Vaccines are another area where data loggers are important for safe handling, as Dickson mentions here.

Healthcare/Hospital

The healthcare industry relies on digital data loggers in many different applications. Ranging from medical device manufacturing and hospitals to blood banks, operating rooms, and cold storage facilities for organs and blood, temperature and humidity values must be consistent. Data loggers are used to verify that standards set by the Food and Drug Administration (FDA), World Health Organization (WHO), and Vaccines For Children (VFC) are met and maintained. This is essential when sensitive assets are being kept in storage for later use or transported to other health facilities for analysis or use. Hospitals use data loggers to keep operating rooms at consistent temperatures, to provide comfortable conditions throughout the rest of the facility for patients, visitors and staff. Environmental conditions must also be correct in the food services part of every hospital to ensure food is stored properly and prepared in a safe environment.

Food & Beverage

Digital data loggers are used in many applications related to the food and beverage industry. They appear in the production, storage, and transportation of goods. Data loggers are also essential tools in commercial kitchens, grocery stores, and retail facilities where food safety is important. The most commonly used data loggers in these settings are those that track temperature, humidity, pressure, and differential pressure and are in place to verify that compliance measures are being met and maintained as required by regulatory bodies including the Food and Drug Administration (FDA), Food Safety Modernization Act (FSMA), and Hazard Analysis Critical Control Point (HACCP). Digital data loggers also assist in monitoring in-house quality control measures. The main purpose of monitoring equipment in the food and beverage industry is to ensure that cooked and raw food is kept at temperatures and humidity levels that do not promote spoilage through the development of harmful bacteria.

Aerospace

Aerospace manufacturing relies on the guidelines provided through AS9100 and ISO 9001 standards. During the production phases, environmental conditions have to be constant once they have met the guidelines set out in the industry standards. The strict controls in place for the manufacturing of aircraft parts such as wings, engines, and turbine blades, are to ensure that these finished products meet the quality and safety requirements needed before they can be used in the construction of an aircraft. Digital data loggers that monitor temperature and humidity are used in various locations throughout the manufacturing production line because even slight variations in the environmental conditions can hamper the integrity of the parts being made. These issues can result in damage to critical electronic components and even structural parts which could then lead to a failure of some kind later. Data loggers can prevent these incidents from occurring by providing a set of “eyes” to watch the conditions under which these parts are manufactured.

The Benefits of Digital Data Loggers

Digital data loggers have many benefits that make them the logical choice for applications where environmental conditions require monitoring. They are small, durable, and effective devices that can withstand harsh environments and still do their job without hesitation or issue. The data collected can be recorded in pre-programmed intervals with information sent to specific personnel via text message or email. The data can be stored on an internal microprocessor, downloaded when needed and analyzed in chart or graph form for a better visual understanding of what the measurements mean and show hard evidence of potential deviations in those standards.

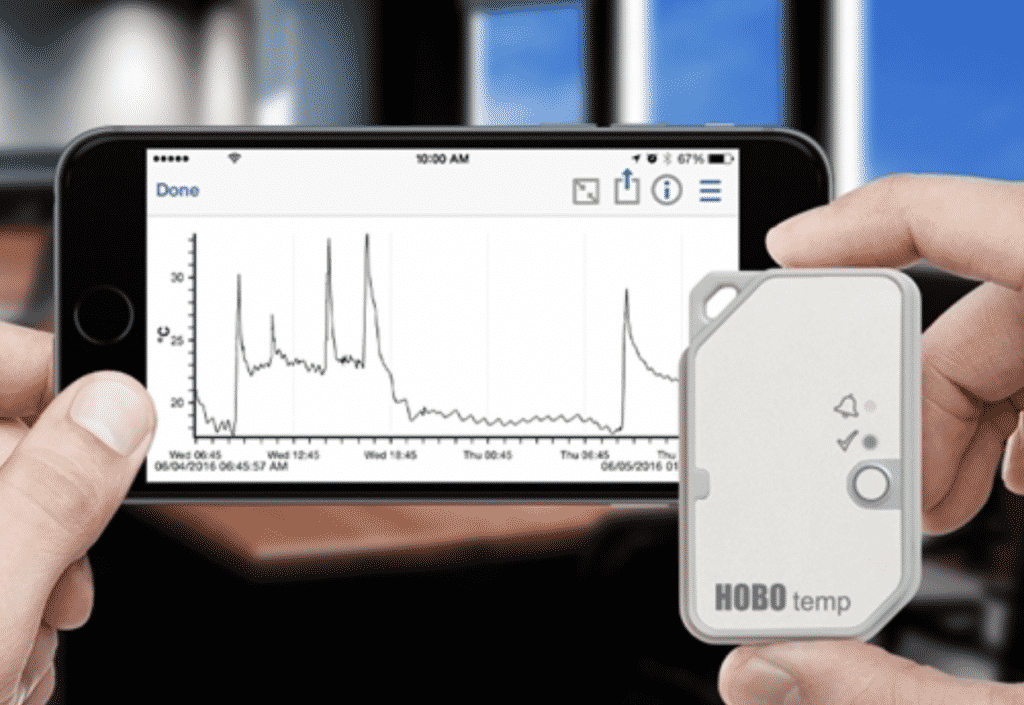

Or the data can be sent directly to a smartphone for real-time analysis. Digital data loggers can be programmed to send alerts directly to the individuals who need to know that compliance issues are at risk so that corrections can be made to prevent a loss of inventory. These versatile devices provide the necessary proof to show that standards required in regulated industries were met and remained consistent. Plus, because they are digital, the readings collected are far more accurate than what would be possible with any other type of measuring tool such as analog.

Conclusion

Digital data loggers are amazing devices. They have become valuable tools in tracking and proving that compliance standards have been met. As a result, these devices are crucial to operations in several different industries. Digital data loggers are commonly used in the pharmaceutical industry, in healthcare and hospitals, in the food and beverage industry, and aerospace. With internal sensors or external probes, these devices can sample and record temperature, humidity, pressure, and voltage depending on the setting and the specific requirements within the industry for which they are being used. When safety standards make a difference in your business, a data logger verifies that standards are being met and maintained when necessary.