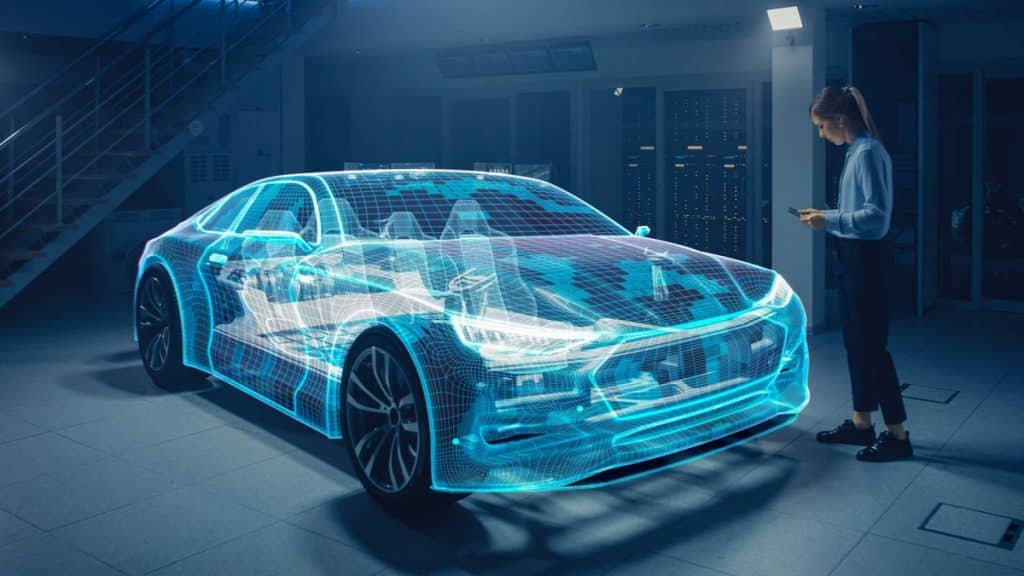

Picture this: before a single car rolls off the production line, it’s already traveled millions of virtual miles. This isn’t sci-fi—it’s the magic of digital twins, revolutionizing the automotive industry. A digital twin is essentially a clone, but instead of biological, it’s digital. It mirrors every aspect of a physical car, from the engine’s purr to the sleekness of the dashboard, all in a virtual world. This tech isn’t just cool; it’s reshaping how cars are born and thrive on the road. So, let’s delve into the digital twin automotive industry deeper.

Unpacking the Perks: Why Digital Twins?

Rethinking Design and Production

- No More Guesswork – Imagine tweaking designs and materials on a computer and testing them under extreme conditions without wasting a dime on materials. Digital twins make this possible, slashing development costs and time.

- Custom Rides Made Easy – Ever wanted a car tailored just for you? Digital twins help manufacturers tweak their assembly lines to build custom cars without breaking a sweat or the bank.

Smoother Operations on the Factory Floor

- A Crystal Ball for Maintenance – These smart systems predict when machines will hiccup or halt, keeping things running smoothly and saving precious time and money.

- Keeping Quality in Check – With real-time data, any slip in quality is caught instantly, ensuring only the best parts make it to assembly.

On the Road: Driving Made Smarter

- Stay in the Know – Once the car hits the road, its digital twin keeps collecting data, offering insights to keep it running in top form.

- Future Fixes, Today – The data also helps predict potential issues, making maintenance a breeze and extending the car’s life.

Digital Twins in Action: Real-World Marvels

It sounds like the future, but it’s happening now. Cars are safer thanks to simulated crash tests that happen in the digital realm. Manufacturing lines adjust in real-time to reduce waste and increase efficiency. Even after you buy a car, its digital twin keeps working for you, customizing maintenance to fit your driving and enhancing reliability.

Navigating Challenges: What’s the Catch?

Sure, digital twins sound great, but they’re not without their hurdles.

Data Overload

- The Issue – There’s a ton of data to handle.

- The Fix – Robust data systems and cutting-edge analytics are the keys to managing the flood.

Cybersecurity Threats

- The Issue – More connectivity means more chances for cyber mischief.

- The Fix – Strong cybersecurity measures are essential to keep data safe and sound.

Upfront Costs

- The Issue – Starting can be pricey.

- The Fix – Spread out the expenses with a step-by-step investment plan to ease the financial burden.

Teamwork Makes the Dream Work: Collaborating for Success

Digital twins thrive on collaboration across tech companies, academia, and suppliers. This synergy not only fuels innovation but also paves the way for seamless integration of new technologies. Ensuring everyone’s on the same page, from the ground up, with solid IT and ongoing education, keeps the digital twin machine humming.

Leveraging Digital Twins for Sustainable Automotive Practices

Driving Towards a Greener Future

As the world grows more environmentally conscious, the automotive industry is under increasing pressure to reduce its carbon footprint. Here’s where digital twins can really shine by contributing to sustainability:

· Efficient Resource Management – Digital twins streamline the entire manufacturing process, reducing waste of materials and energy. By simulating production processes and assembly lines, companies can identify inefficiencies and optimize the use of resources.

· Eco-friendly Design Optimization – Before a new model ever hits the road, its digital twin can be used to test and enhance features that improve fuel efficiency and reduce emissions. This might involve experimenting with lighter materials or more aerodynamic designs, all in a virtual setting.

· Lifecycle Management – Digital twins track a vehicle’s performance from cradle to grave. This comprehensive data allows manufacturers to improve not just the vehicle’s operational efficiency but also its recyclability at end-of-life, ensuring parts can be reused or disposed of properly.

Your Questions, Answered

· Q1: How accurate are digital twins?

- A1: Very! Their precision hinges on the data quality and model complexity. Regular updates keep them sharp and reliable.

· Q2: Can digital twins help electric vehicles too?

- A2: Absolutely! They’re game-changers in managing battery life and overall energy efficiency.

· Q3: Are older cars left out of the digital twin revolution?

- A3: Not at all! Digital twins can be retrofitted to spruce up older models, too.

Wrapping Up: The Road Ahead

Digital twins are more than a fleeting trend—they’re pivotal to smarter, safer, and more efficient driving. As we cruise into the future, these virtual virtuosos are set to revolutionize not just how we make cars, but how we maintain and enjoy them.