The Global Manufacturing Industry is still recovering from the impact of the pandemic of Covid 19. According to a study, the industry lost almost $8 trillion in value in 2020 due to the COVID-19 pandemic. However, advanced technologies like cloud computing, edge computing, IoT, and many more are helping the manufacturing industry to move toward the path of growth. A study by Deloitte highlights that 86% of surveyed manufacturing executives believe that innovative factory solutions will be the primary drivers of competitiveness in the next five years.

Now, there is no doubt that implementing next-generation technologies will be compulsory for all manufacturing businesses to increase efficiency and stay competitive. One of the most important and transformative solutions most businesses are adopting is edge computing. Manufacturers find it difficult to manage large volumes and unstructured data with existing cloud services, and to overcome these challenges; they are moving towards Edge computing.

Edge computing is a distributed computing model where data processing occurs at the network’s edge, which means it is closer to the source of data generation rather than relying completely on centralized cloud resources. Because of this, it can help you with fast data processing and make quicker decisions, eliminating the need for sending data far away to centralized servers. Ultimately, It can bring better performance and efficiency to your manufacturing operations.

Doesn’t it fascinate you the way Edge Computing can reshape your manufacturing cycle? We know that edge computing holds immense power to bring efficiency to manufacturing, and we want you to leverage this power for your production operations. That’s why, in this article, we will talk about the use case of edge computing in manufacturing, why it is important, and how you can integrate edge computing in your manufacturing operations. So, let’s dive into the topic and understand everything about edge computing in manufacturing.

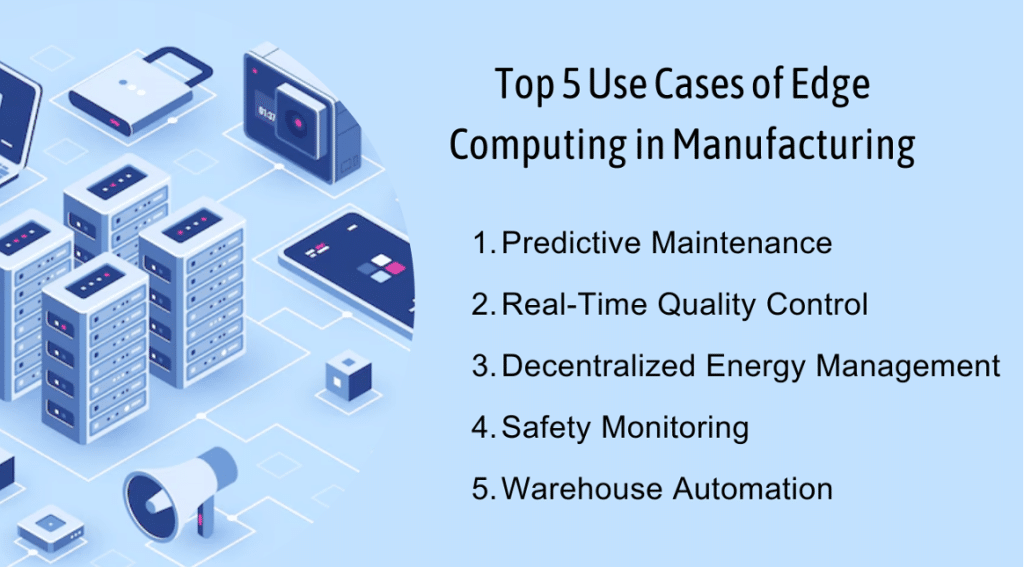

Use Cases of Edge Computing in Manufacturing

Following are the Top 5 Use Cases of Edge Computing that are important in the manufacturing industry.

1. Predictive Maintenance

Predictive maintenance is one of the most important use cases of edge computing. It increases the uptime of your machines by predicting damage in advance. It utilizes and analyses real-time data from machines, and rather than sending it to one centralized server, the edge networks analyze predefined damage patterns. And wherever it finds any pattern of potential damage, it will alert you in advance so you can make arrangements for repair or replacement before actual damage occurs. It will prevent any major damage to machinery and help you to increase efficiency by reducing repair costs. Most importantly, you can now meet deadlines without compromising on quality.

2. Real-Time Quality Control

Quality is the king of manufacturing. Imagine the loss of your reputation you have to face if any customer gets a damaged product from your hand. Low-quality products are one of the major reasons for customer dissatisfaction and financial loss. Edge Computing has a solution for this problem. Sensors embedded in machinery or the production line capture real-time data on different parameters like temperature, humidity, and pressure. If anything is not appropriate according to the product’s need, it will indicate to you that you need to fix it. Additionally, it can find defective products in the assembly line and ensure that they are not delivered to the customer.

3. Decentralized Energy Management

In the factory, there are many machinery of different sizes that consume different amounts of electricity or other energy. Decentralized energy management leverages the power of edge computing to access the real-time data of the usage of electricity and energy of each machine and tool. From the data, you can plan and forecast future resource needs and avoid wasting resources. It is the cost-savvy and sustainable way of utilizing energy in your manufacturing operations.

4. Safety Monitoring and Incident Prevention

Many a time, major accidents happen in factories where labors get seriously injured or sometimes meet with death. As a manufacturer, ensuring labor safety is your responsibility, and edge computing can help you with this. By analyzing sensor data and machine behavior in real-time, the edge sensors can catch slight changes in vibration and temperature or identify any other potential hazards. The advanced system can also trigger automated safety protocols, like machine shutdowns. Thus, you can build a safe manufacturing environment for your laborers.

5. Warehouse Automation

A warehouse is one of the most important parts of manufacturing, whether for storing raw materials safely or for storing manufactured products to meet future demand. Edge computing processes data from sensors, robots, and other warehouse systems in real-time, so there is no need to send this data to a centralized system. The edge network will analyze data and make decisions to forecast future inventory needs. It will also remind you to despatch the orders. Thus, edge commuting can decentralize decision-making and automate warehouse operations.

From the use cases mentioned above, you must have an idea of the importance of edge computing in the manufacturing industry. But, to make it clearer, let’s briefly discuss the benefits of edge computing in manufacturing.

Benefits of Edge Computing in Manufacturing

- Edge Computing can save you from costly downtime by predicting damage early.

- It can process data locally for the machines, so there is no need to send everything to the cloud. Thus it can potentially lower your cloud storage costs. And you don’t need to rely on the internet to keep things running smoothly constantly.

- Storing and processing sensitive data locally also reduces the risk of cyberattacks to solely cloud-based solutions.

- It’s a cost-saving approach because the less data you send to the cloud, the more you have to bear, and you can reduce potential cloud fees.

- With the help of edge computing, you can predict any defect in machinery before it causes major damage, thus increasing its life.

In short, it can help you to make faster and better decisions, increase efficiency, improve customer satisfaction, manage inventory better, and maintain your machinery.

Now, we are clear about the importance of edge computing in the manufacturing industry, but the main question is how to integrate it into your manufacturing operations. So, let’s discuss the simple four-step process for utilizing edge computing in your manufacturing operations.

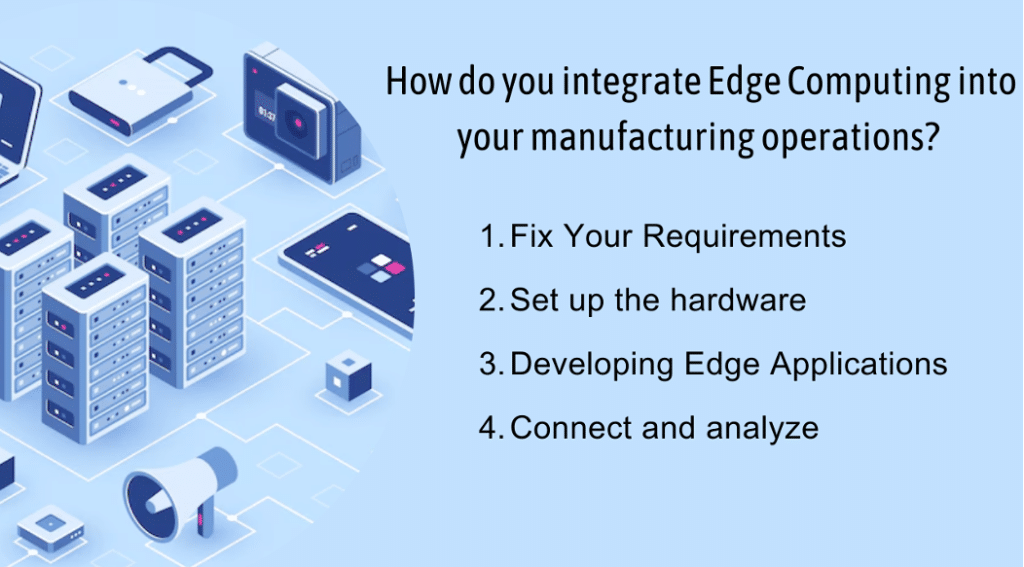

How do you integrate Edge Computing into your manufacturing operations?

1. Define Your Requirements

Decide what you want to achieve with edge computing. Choose a specific area where real-time data can improve things, like predicting machine failures or optimizing production lines. Think about areas where faster decisions or immediate actions could make a big difference.

2. Set up the hardware

You need some specific hardware to utilize edge computing. Hence, you need to install devices like gateways or industrial computers near your machines to collect and analyze data.

3. Developing Edge Software

This is a crucial step. You need special applications and edge software that can work properly in edge hardware and perform real-time data analysis, machine learning algorithms, and decision-making processes close to the data source. For this, you need to hire software developers with expertise and experience in developing edge computing-based software and applications for the manufacturing industry.

4. Connect and analyze

Install edge computing-powered software in your device and link these devices to your existing systems or software to use the data for faster decisions and improvements.

In conclusion, we can say that edge computing presents a transformative opportunity for the manufacturing industry. Those days are gone when delays in machinery repair were costing you high downtime expenses, your customers were getting disappointed by low-quality products, or you were paying a high cost for cloud service. It’s time to invest in edge computing to streamline all manufacturing operations and increase efficiency in your production cycle. Big companies like Coca-Cola, Schneider Electric, Bosch Rexroth, and many more are leveraging the power of edge computing to increase efficiency in their manufacturing operations. So, we can say that edge computing is no longer an option but a necessity for manufacturers seeking efficiency in their operations.