Computer Numerical Control (CNC) technology has made remarkable strides in recent years, transforming the manufacturing landscape. The precision and efficiency offered by modern CNC machines have set new standards in production processes. This article delves into the significant advancements in CNC technology and their impact on the manufacturing industry.

CNC technology is rapidly evolving, providing unprecedented capabilities to manufacturers. By automating complex machining tasks, CNC systems enable higher precision, reduced waste and enhanced productivity. Understanding these advancements is crucial for businesses aiming to stay competitive in the dynamic manufacturing sector.

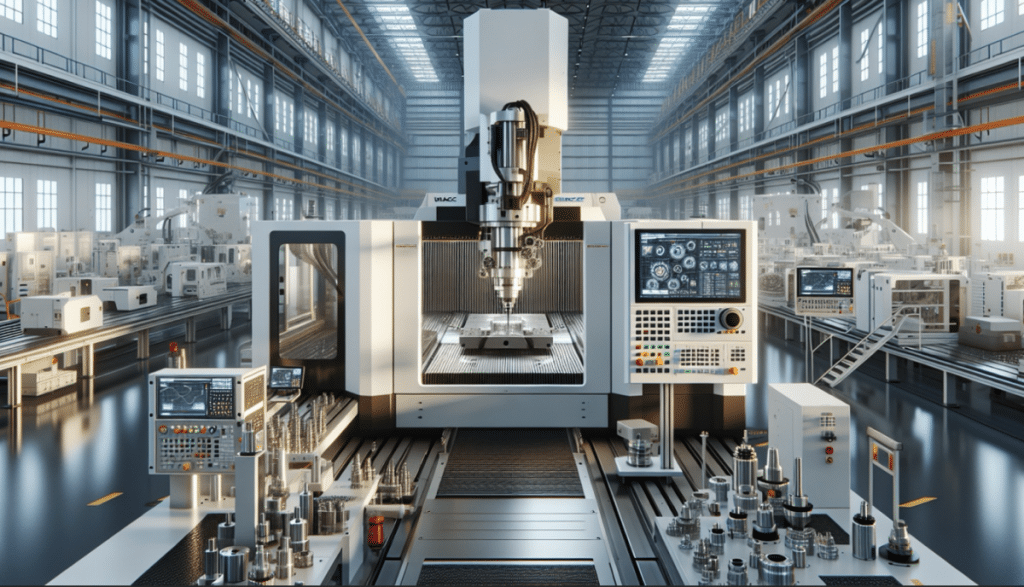

Precision and Efficiency: Key Benefits of Modern CNC Technology

One of the most notable advancements in CNC technology is its precision and efficiency. Modern CNC machines can perform intricate operations with remarkable accuracy, significantly reducing human error. For instance, a CNC router can achieve tolerances as low as a few microns, ensuring consistent product quality. This level of precision is particularly beneficial in industries such as aerospace and medical devices, where exact specifications are paramount.

Additionally, advanced CNC systems incorporate real-time monitoring and feedback mechanisms. These features allow for immediate adjustments during the machining process, further enhancing accuracy and reducing material waste. The combination of precision and efficiency not only improves product quality but also optimizes production costs and timelines.

The integration of advanced sensor technology in modern CNC machines has also significantly enhanced their precision capabilities. These sensors can detect minute variations in temperature, vibration, and tool wear, allowing for real-time adjustments to maintain optimal cutting conditions. This level of adaptive control ensures consistent quality even in long production runs, reducing the likelihood of defects and minimizing the need for quality checks. As a result, manufacturers can achieve higher throughput and lower rejection rates, leading to improved overall equipment effectiveness (OEE) and reduced production costs.

The Role of Automation in Transforming Manufacturing Processes

Automation plays a pivotal role in the evolution of CNC technology. Modern CNC machines are equipped with sophisticated software that can automate various aspects of the manufacturing process. In many cases, operators can simply input design specifications into the system, and the machine takes care of the rest. This automation streamlines operations and minimizes manual intervention.

What’s more, advanced CNC machines often feature multi-axis capabilities, enabling complex geometries to be machined in a single setup. This reduces the need for multiple fixtures and setups, saving time and increasing overall efficiency. The integration of automated tool changers also enhances flexibility, allowing for seamless transitions between different machining tasks.

Impact on Small-Scale Manufacturers

The advancements in CNC technology are not limited to large-scale industrial applications; they also hold significant benefits for small-scale manufacturers. With the advent of affordable and user-friendly CNC machines, smaller businesses can now access high-precision manufacturing capabilities that were once reserved for larger corporations.

This democratization of CNC technology levels the playing field, enabling small-scale manufacturers to produce high-quality products with greater consistency. As a result, these businesses can compete more effectively in the market, offering custom solutions with shorter lead times.

Looking Ahead: Future Trends and Innovations in CNC Technology

The future of CNC technology looks promising, with ongoing research and development driving further innovations. One emerging trend is the integration of artificial intelligence (AI) and machine learning into CNC systems. These technologies enable machines to learn from past operations and optimize future processes autonomously.

Additionally, advancements in materials science are expanding the range of materials that can be processed using CNC technology. From advanced composites to new metal alloys, these developments open up new possibilities for innovative product designs. As these trends continue to evolve, it is essential for manufacturers to stay informed and adapt to maintain their competitive edge.