Robotic arms play a crucial role in industrial automation. They are programmable mechanical devices. They perform physical, repetitive tasks with precision. Robotic arms offer manufacturers substantial benefits through increased productivity, flexibility, and accuracy. While they aim to improve production, different types of robotic arms are suited to diverse manufacturing needs.

Robotic Arms: Advantages

There are several key advantages of implementing specific types of robotic arms for automation. These include (but are not limited to):

1. Increased Productivity

Robotic arms can work continuously 24 hours a day. This enables them to rapidly perform repetitive physical tasks at a steady pace. They largely boost a production line’s output. The high speeds and precision ensure they can maximize throughput and meet high-volume manufacturing demands.

2. Higher Accuracy

Robotic arms precisely repeat the same motions systematically without deviation. They maintain accuracy and consistency in assemblies that can be demanding for human workers. The consistent quality assured by robotic arms is vital for various industries such as electronics.

3. Improved Flexibility

Specific types of robotic arms, such as collaborative robots, have an advantage in their flexibility. Through software adjustments, they can quickly adapt to changes in production lines. This flexibility simplifies the process of incorporating product upgrades or variants using the same robotic systems.

Types and Applications of Robotic Arms

There are many types of robotic arms. Some of the most common types include:

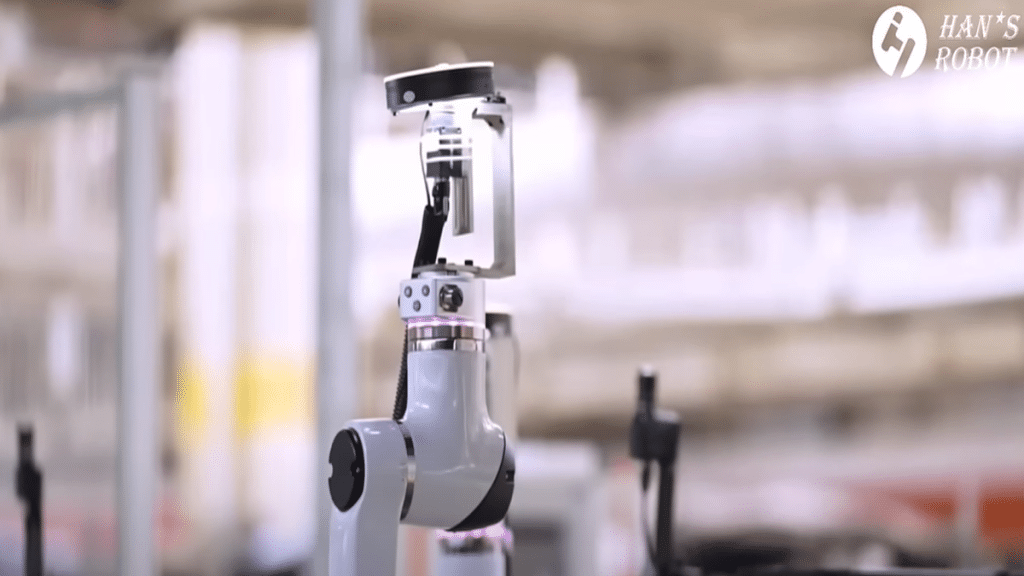

1. Collaborative Robotic Arm

Collaborative robots, or cobot arms, are designed with inherent protection features such as torque and position limiting. Cobot arms facilitate applications requiring human-robot interaction without isolating barriers. The lightweight construction, ease of programming, and high safety enable diverse applications. These include 3C, automotive, healthcare, metalworking, and more.

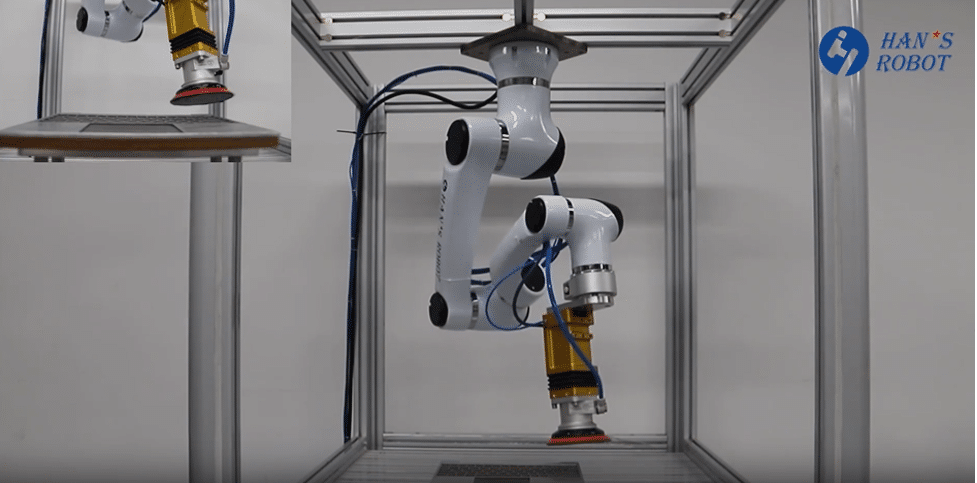

2. Cartesian (Gantry) Robotic Arm

This industrial robotic arm moves in straight lines along three principal axes (X, Y, and Z). It can precisely manipulate large payloads within extensive three-dimensional spaces. It is suitable for tasks like material handling, machine loading/unloading, and product assembly. It is used in industries like automotive, medical devices, and electronics manufacturing.

3. Cylindrical Robotic Arm

This type of industrial robotic arm is capable of full rotation around a vertical pole or pillar. It can efficiently position components or objects around it. Common applications include palletizing, packaging, and assembly within circular work cells. These arms readily access all angles equidistant from their centralized axis of motion. The large payload capacity supports packaging and light manufacturing uses.

4. Spherical (Polar) Robotic Arm

One of the common types of robotic arms, the spherical robotic arm, can maneuver within three-dimensional spherical coordinates. This industrial robotic arm flexibly inspects products or handles payloads from any radial or azimuthal angle. It optimizes quality assurance tasks needing multi-planar assessments. These include appearance checks of automotive bodies.

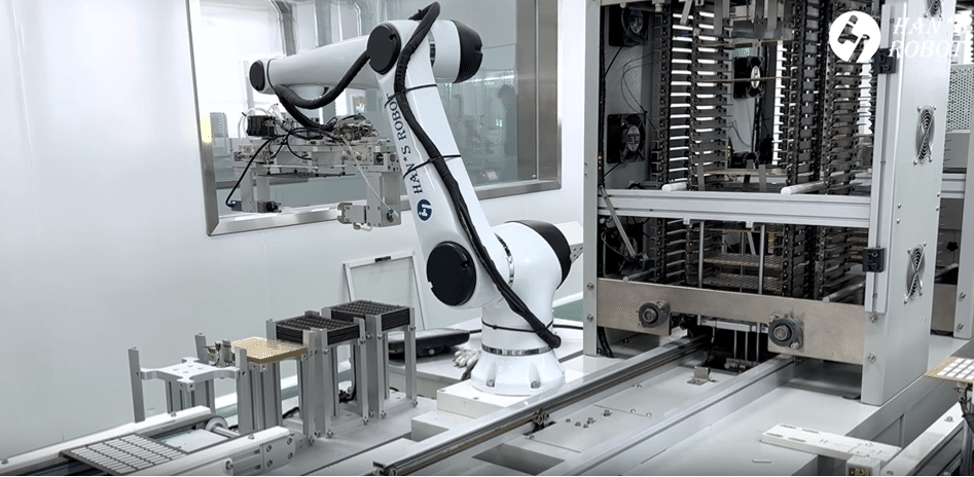

5. Anthropomorphic Robotic Arm

This type of robotic arm closely mimics the human arm’s seven degrees of freedom. It can skillfully perform complex manual jobs with a delicate touch. These include electronics assembly, small parts insertion, and more. The robotic arm’s bio-inspired design supports applications requiring deft motions. It’s especially valuable for handling fragile components.

6. SCARA

SCARA (Selective Compliance Assembly/Articulated Robot Arm) features a parallel-axis joint design. It is slightly compliant in the X-Y direction but rigid in the Z direction. It specializes in high-speed pick-and-place tasks within a narrow work area. This type of industrial robot is optimized for repetitive high-precision jobs like parts placement, packaging, dispensing, and kitting.

Conclusion

Overall, the various types of robotic arms have become invaluable for modern manufacturing. They offer key advantages in productivity, accuracy, and flexibility. Whether cartesian, cylindrical, or other designs, manufacturers can find robotic arms suited to their specific automation needs and applications. As a top cobot manufacturer, Han’s Robot offers users reliable cobot solutions to maximize productivity. Han’s collaborative robotic arms empower human-robot cooperation.

The specialist cobot manufacturer Han’s Robot develops intelligent robots such as cobot palletizers, welding cobots, sparying cobots, CNC cobots, etc., through its R&D expertise. Its focus on research and development has led to the creation of diverse innovative robots. Its Elfin and Elfin-Pro collaborative robot product series are well-known in the industry. Visit Han’s Robot’s website to learn more about these advanced solutions.