The use of timber for decking has been significantly reduced over time. Can you think of a reason? Let me tell you why it has happened. The appearance of WPC composite decking changed the decking and flooring trend. Today people are investing in this technology more than ever before. In this article, we will discuss WPC composite decking in detail and will tell you about the evolution of WPC composite decking.

What is a Wood Plastic Composite Decking?

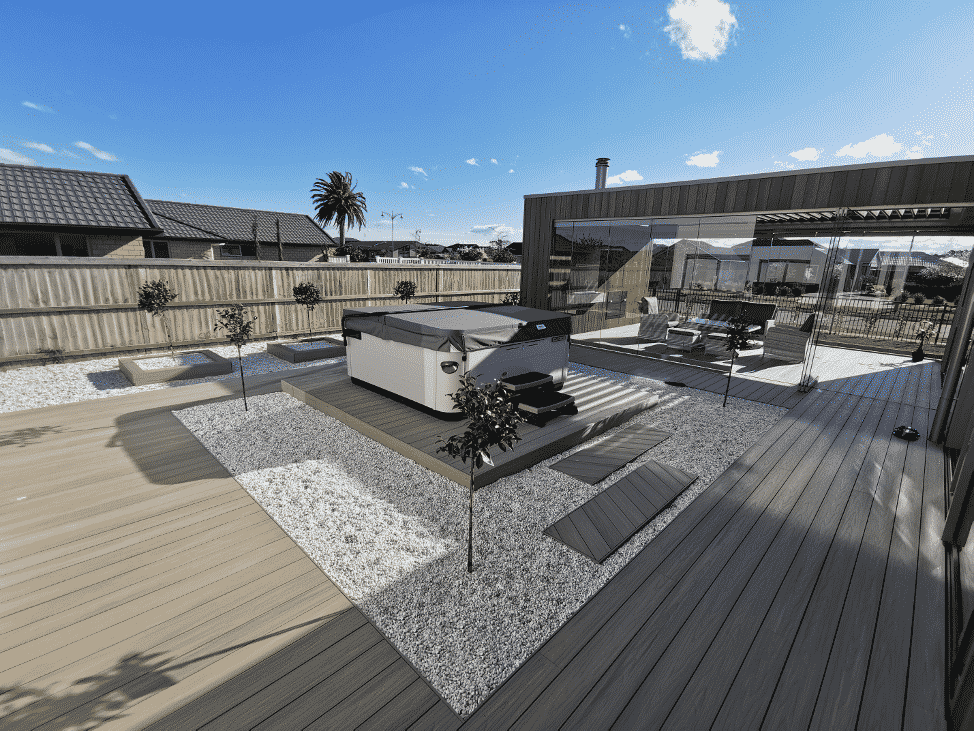

WPC has been a popular alternative for decking and flooring due to its exquisite design and color diversity. Wood-plastic composite decking is made out of wood fibers and plastic, making it an extremely durable and sturdy material. In addition to the primary raw material for WPC decking production, other materials used in the manufacturing include lubricants, antioxidants, light-stabilizers, etc., to produce the perfect WPC composite decking.

A brief History of the Composite Decking

Even though WPC seems to be a new phenomenon, it has been around for quite some time now. In the 1980s and 1990s, the United States pioneered the use of plastic wood. Companies like Woodstock and Trex employed polyethylene, wood flour, polypropylene, or wood fiber in the manufacturing of wood composite material to produce car liner boards, flooring, picnic tables, and many other products. Wood composite decking entered China in the mid-1990s, but in no time, it surpassed the United States to become the world’s largest producer and distributor of WPC composite decking. Over the years, great improvements were made to make them more durable, strong, scratch-resistant, moisture-resistant, etc. The major evolution occurred with the invention of co-extrusion composite decking (also known as capped composite decking), which was very strong, anti-slip, mould-proof, and durable compared to 1st generation composite decking.

The Status of Global Composite Decking

Due to the benefits and properties of composite decking, they are preferred by almost everyone today. Composite decking has a huge market share in today’s competitive market. The decking market is expected to grow by $4.19 billion in the next four years, and it is progressing at a CAGR of over 5%. The technology is evolving into an amazing substitute for natural timber, and they are environmentally friendly, giving them the edge.

The Development Prospects of WPC Composite Decking

Started in the 1980s and developed in the late 1990s, the technology of WPC composite decking has evolved a lot. The primary aim of WPC wood plastic composite is to make it a complete substitute for natural timber, improve the material properties, and reduce the overall cost of its installation and maintenance. Furthermore, it is the need of time to bring more improvements in the quality and reduction in cost.

Why Should you Choose Wallong as your Composite Decking Supplier?

If you’re seeking high-quality wood plastic composite decking (WPC decking), Wallong should be your first stop if you need some convincing arguments to pick Wallong. There are a bunch of reasons that will back up your decision. The top three causes are given below.

Multiple Authoritative Certifications

With over 13 years of experience, Wallong has acquired various national and international certifications. With all these certifications, Wallong is confident that they devise the highest-quality products.

Powerful Technical Team

Wallong being a leading WPC decking manufacturer and distributor, has a highly specialized and experienced technical team. The R&D team strives to produce the best WPC decking solutions for commercial and residential customers.

A Variety of High-Quality Products with High-Cost Performance

Wallong is committed to offering high-quality items that are also cost-effective. Thousands of customers from all around the world purchase their items. Wallong is currently one of China’s fastest-growing and top WPC producers, with a reputation for quality and innovation.

Conclusion

Wood-plastic composite material fully embodies a series of advanced concepts such as resource utilization, health and environmental protection, circular economy, and sustainable development. In recent decades, the development of wood plastic has continued, and more and more factories are eager to try in this industry. Many factories focus on adding production lines, improving advanced equipment, increasing market research and development, and producing high-end products in the production process. Wallong as a leading manufacturer has 50 latest production lines and a strong technical team and equipment. They carry out strict quality control on products and innovate new products.