What is a Bread Crumb Production Line and How Does It Work?

Exploring the Extrusion Phase for Bread Crumbs

Most advanced provision for bread crumb production is the extrusion process that facilitates the conversion of the crumbling of the bread into uniform and crispy bread crumbs. This operation is accomplished through some interrelated certain components which work together for the final requisites.

、If you are looking for more information about Bread Crumbs Production Line – Loyal go here right away

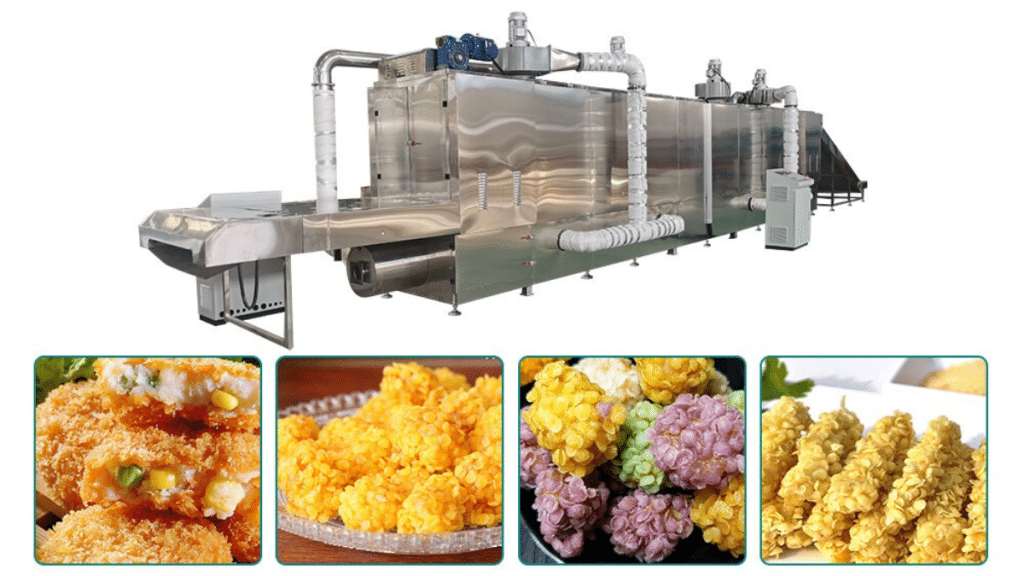

Crucial Elements of A Bread Crumb’s Processing Line

Feeding System: The feeding system maintains a controlled flow of bread slices or loaves to the rest of the line, which could be done by a conveyor belt or an automated feeding system.

Cutting System: The cutting unit is responsible for cutting the bread into desired lengths and heights to allow even edges. This step is vital for achieving the proper cut size and texture, as well as preventing the crumb from being formed all in one place.

Drying System: After slicing the bread, it goes through the drying system, which uses infrared or hot air, depending on the requirement. The removal of moisture content renders dry and crisp crumbs after this process.

Grinding System: Sliced and dried bread pieces are input into the pulverizer in a grinding system. The cutter rotates within the grinding wheel and reduces the size of the bread to the desired chunk size.

Sifting System: As the name suggests, this system would be responsible for the growth of bread sieve particles on the Basis of crump density. This, after all, guarantees consistency by getting rid of large and other undesirable particles from the product.

Packaging System: Packaging bread crumbs in suitable containers or polythene bags takes the last place in the incompleteness of the product which means the bread making is done.

For more in-depth information, you should view the Bread Crumbs Production Line – Loyal.

Traditional and Advanced Methods for Making Bread Crumbs: A Comparison

Breadcrumbling, shredding and toast burning bread are done manually in most cases in traditional methods it is common and easy but the quality of cut is highly inconsistent. On the other hand, Modern bread crumb production methods are highly automated and require advanced mechanical inputs ensuring high output and even texture cut on bread. Businesses with a modern approach to their bread crumb production will definitely have a wider scope and reach for the product.

What are the benefits of investing in a bread crumb-making machine?

Maximized Effectiveness and Turnover in Bread Crumb Manufacturing

Modern bread crumbs-making machines are a great investment for business operations in the bread crumbs sector. One of the obvious benefits of introducing advanced automation and precision machinery is that it enhances production processes and increases the quantity and speed of output as well as quality and consistency at the same time. So, these machines are able to replace a huge amount of bread, which makes the whole production cycle much more efficient, and more importantly, cuts down on the amount of labor needed. This results in a tremendous increase in business production which enables them to cope with the current growing market and competition.

Rapid Tertiary Production of Bread Crumbs That Are High-Quality And Have Good Texture

A panko bread crumb is especially a good option because it has a wide range of uses in the culinary and food sectors. One of the advantages of having to buy a bread crumbs production line is the ability to have both the panko bread crumbs and the regular bread crumbs. Investing in a specialized breadcrumb machine minimizes the chances of having inconsistencies in the output of high-quality panko breadcrumbs. Through the machines cutting and grinding in a breadcrumb machine is a highly precise operation. Thus, the final product which has been produced will approximately be of the same size and texture and can satisfy consumers or professional chefs who, apply very strict standards.

Cost Efficiency of Automated Bread Crumb Processing

The companies which use automatic machines, do not only increase the efficiency and quality of bread crumb processing, but they also decrease the costs for their bread production. Automatic machines are able to do many processes after replacing the skilled manual workforce, thus economizing on labor while reducing the chances of errors occurring. Moreover, automated production lines are also geared towards the effective use of ingredients, thereby reducing wastage. These cost-effective attributes bring about enhanced profits and an advantage over the competition in the market.

The investment in a bread crumb production line as strategic planning will offer many advantages such as enhancing the rate of panko bread crumbs processing, better quality and consistency of the resulting output, and reducing the cost of more efficient automatic bread crumb processing. The right machines change the game for the segments allowing them to satisfy the market without declining the quality of the products.

How to Choose the Right Bread Crumb Production Line for Your Business?

Evaluating Production Capacity and Number of A Bread Crumb Line

In the selection of a breadcrumb production line for your company, it is vital to look at whether your production capacity and output requirements will be met. Yes, consider the amount of breadcrumbs needed to be produced as per the market, production time frames, and scope of growth. Check various machinery options to see if they will meet the production quotas that you wish to establish.

Comparative Analysis of Various Bread Crumb Cutters

It’s notable that among the offered devices on the market, they differ in their design solution and intended purpose. Try to research the various models and brands and identify the machines that are conducive to your requirements. How effectively and reliably is it able to perform the production processes, how easy is it to operate and how difficult is it to clean.

Other Factors that Might be of Interest: Does your Production Line Have the Capacity to Make Regular and Panko Bread Crumbs?

Variable production capabilities of the bread crumb machines should automatically be a consideration when purchasing a bread crumb production line. Ask whether the machines can handle the processing of regular, panko or both since this increases the scope of the market that one is able to serve. Opt for machines that are easily adjustable and can enable one to produce bread crumbs of different sizes.

Considering the abilities of your business, looking at the various possible machinery, and scope of expansion, will guide you in making a better option on the most suitable bread crumb production line for your company. With this, an efficient and economical automated system for processing bread crumb is achieved enabling you to meet market needs while enhancing the quality of the products.

What Raw Materials and Ingredients Are Needed for Bread Crumb Production?

Selecting High-Quality Ingredients for Premium Bread Crumbs

The type of bread, the main ingredient for making any bread crumb, is crucial in achieving the desired quality bread through selecting appropriate candidates in the beginning. This makes the importance of the ingredients even higher as they have the capacity to influence reserves, mouthfeel and general sensory properties. It is the ingredients that make a product a target.

Factors to consider while optimizing for high quality:

- Bread Selection: The base ingredient when producing bread crumbs is bread. Therefore, it is best to use fresh , crumb structure’d and neutral flavored bread or even slightly stale bread. However, the choice of bread varies due to end product variations of the required flavor and texture.

- Moisture Content: When it comes to flavor enhancement, the consideration of moisture content is important, as its combination with oil tends to give bread crumbs an appealing tactile sensation. It is advisable to utilize olive oil, vegetable oil or even melted butter in controlled amounts ideally between 10-12% of the total formulation to create optimal bread crumbs.

- Seasonings and Spices: When produced in conjunction with bread crumbs, Paprika, cayenne pepper, garlic powder and onion powder can be added to improve the organoleptic profile further. The same applies to oregano and thyme if dried herbs are included.

- Oil or Fat: During the bread crumb manufacturing, a controlled portion of fat can also be added to the crkmbs through the use of oil and other products which should improve the corresponding hardness and also how the product is consumed.

Exploring Alternatives for Gluten-Free Bread Crumb Production

As the need for gluten-free products continues to grow, increasing your inventory to include gluten-free bread crumbs may be a profitable move for your company. Check out these substitutions to make your breadcrumb gluten-free:

- Gluten-Free Bread: One of the options can be making use of gluten-free bread. Gluten free breads have a very specific texture that comes from a unique combination of flours such as rice flour, corn flour and sometimes, almond flour. Try and find such bread products that come in a variety of flavors with a crumb-like texture that’s fluffy enough to complement other ingredients.

- Alternative Grains and Seeds: Furthermore mix in grains such as quinoa or millet or even buckwheat and flaxseed to further elevate the nutritional value and texture that is required in the gluten-free bread nuggets. Try out several combinations to obtain the right taste and texture.

- Gluten Free Flavoring Agents: There are many other gluten-free products like seasoning gluten bread that can give further flavoring to gluten free bread nuggets. Since gluten-free is one of your major selling points, be sure that all other substances utilized are also marked gluten-free i.e. spices, additives, and even seasonings.

By sourcing the best quality products and putting them together in the right way, you can create premium options that would be able to cater to dietary requirements of all kinds – setting you apart from the competition within the industry.

How to Maintain and Clean Your Bread Crumb Processing Line?

Regular Maintenance Tips for Bread Crumb Machinery

Regular maintenance is important in order to keep your breadcrumb processing line functioning normally and possibly extending its lifespan. For your better understanding, here are a few maintenance tips in the list below:

- Scheduled Inspections: All machinery parts should be checked on regular intervals for abrasions, breakage or malfunction. Inspections should cover but not be limited to belts, motors, gears ,and bearings. Routine Damage Control encompasses resolving all issues fast in order to avoid hefty expenses and loss of time as a result of more extensive damage.

- Lubrication: It is important to note that machinery performs specific functions efficiently through lubrication. Suitable optimal performance should derive from manufacturers guidelines of lubrication. Lubricants that are suitable for food processing equipment should be used.

- Cleaning Procedures: There has to be a strict cleaning schedule for each and every equipment especially bread crumb machinery. Building up debris, crumbs and food wastes on equipment surfaces, belts and in conveyors should be done on regular occasions. Approved maintenance chemicals and sanitation protocols should also be used in order to make sure standards of food safety are adhered.

- Tighten Loose Connections: Machinery maintenance protocols and overseers should tighten all bolts and fasteners that may loosen from the influence of vibration on the equipment.

- Training and Documentation: Proper operation, cleaning, and maintenance of the bread crumb processing line should be taught to employees of your company and effective supervision should be observed. Maintenance performed and when it was executed should be recorded in documents so that history and chronology of the equipment is easy to track.

Proper Cleaning Procedures to Ensure Food Safety

In the production of bread crumbs, cleanliness, and food safety practices are the most important. Use these cleaning practices to secure food safety:

- Pre-Cleaning: Remove any bread crumbs and other debris from the machinery prior to beginning cleaning. Loose particles can be effectively removed with air blowers, vacuum cleaners and brushes.

- Disassembly: If necessary, interrupt the assembly of equipment parts according to the manufacturer’s specifications. This enables cleaning of hidden dirt and controls cross-contamination between the equipment and food.

- Sanitization: Apply recommended food grade cleaning agents and other sanitizers for bread crumb equipment. Ensure to adhere to the prescribed dilution ratios and contact times as instructed by the manufacturer. All sides should be rinsed with clean water after the process of sanitization.

- Drying: Ensure that all equipment surfaces are completely dry before being reassembled or production continues. The presence of any moisture favors the growth of bacteria which complicates food safety.

- Verification: Verification of every cleaning practice through visual inspections and microbial testing shall be performed periodically in applicable cases. Allow for documentation of all cleaning activities undertaken and regarding test results conducted as part of a food safety system.

Maintaining discipline when completing scheduled time for maintenance and completing required steps of cleaning the bread crumb machinery practices you are ensuring food safety as well as the performance of the bread crumb machinery and the quality of your products.

What Are the Latest Innovations in Bread Crumb Production Technology?

Developments in extrusion technology to enhance texture

The technology of extrusion has evolved greatly in the past few years, advancing the process of making bread crumbs and their texture properties. With the use of advanced extruding machines, breadcrumb manufacturers are able to have better control on the dimensions, form as well as mass of the crumbs resulting to better texture that is more appealing. These improvements on extrusion technology have contributed in further developing the light and crunch texture of the and general mouth feel of the bread.

Completeness of Quality Control in the Elaboration of Processing Lines for Bread Crumbs

Every time bread crumbs are produced, the quality control of the final products should be the same. One of the ways to achieve this is through the integration of automated quality control in production processes. Such systems include modern developed sensors and computer vision techniques that examine color, size, and shape, among other features, during the production of material. Automated quality control systems enhance every time production by changing any setting whenever output decreases the required parameters, which prevents waste while maintaining quality on the production industrial scale. All the systems in place assist breadcrumb manufacturers in producing breadcrumbs that satisfy the requirements of their buyers.

In this continuously transforming business of bread crumb manufacturing, it is necessary for crumb producers intending to remain competitive to take advantage of these advancements in extrusion technology and automated quality control systems. This would enable producers to improve the quality and consistency of the texture of their bread crumbs, and in turn, increase profitability and keep up with the evolution of the industry.

How to Maximize Profitability with Your Bread Crumbs Production Line?

Reinvention Of Your Product Mix: Developing Varieties Of Bread Crumbs

In order to boost the profit of your bread crumbs production line, it might be useful to expand the product mix. Specifically, you may offer custom dry bread crumb blends for different applications in food service, as your consumers’ needs are changing as well. For instance, you may introduce a seasoned dry breading mix of different flavors, gluten-free, or even gourmet baked ones. This addition can not only accelerate growth in cutting-edge facilities but also widen avenues in entirely new markets.

Lowering Expenditure By Making Improvements In The Production Line

From an outsider’s perspective, efficiency is crucial in order to achieve the highest possible profit. Altering your production methods will achieve the goal of minimizing expenditures and increasing yield. Lean manufacturing may be a useful concept, more specifically, minimizing waste, the flow of processes, and making better use of resources. Production inaccuracy can be decreased, high manual input can be avoided, and reduced production downtime by automating robotic solutions. The ongoing process of self-evaluation and improvement in solutions determines high working efficiency with a low expenditure rate, which is advantageous for profit.

Marketing Plans for Bread Crusts Manufacturers

In order to gain the market and grow sales, marketing has to be done. Formulate a crisp marketing plan that provides details of what sets your breadcrumbs apart from others. If possible, use modern platforms like social media and online ads to promote the brand. Outreach to food bloggers, chefs, and social media influencers to build content that demonstrates the various usage and excellence of your breadcrumbs. Besides, attend and participate in trade fairs and exhibitions to interact with potential buyers of your brand and advertise the brand to make it reputable in the market.

Through the careful expansion of Breadcrumbs’ product lines, increasing production efficiency, and application of good marketing strategies, you can optimize profits on your breadcrumb production line. The inclusion of such plans into your breadcrumbs business will enable you to be in the game, satisfy consumer needs, and achieve goals in the food sector for decades to come.