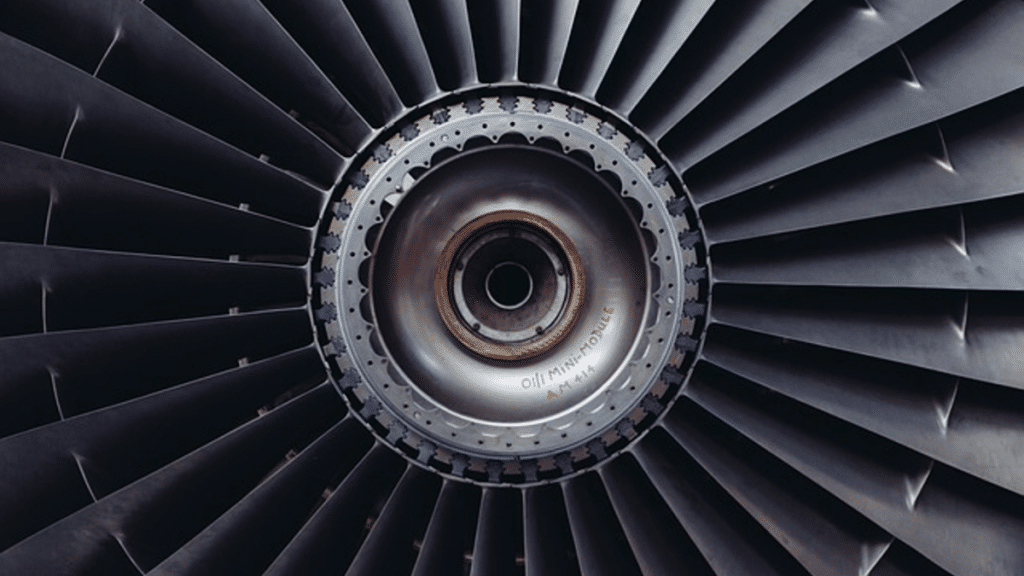

Industrial turbines play a critical role in modern power plants, providing efficient and reliable energy conversion. Whether it’s a gas, steam, or hydro turbine, these machines are designed to transform mechanical energy into electricity with minimal waste. With the growing demand for cleaner and more sustainable energy solutions, improving efficiency in power generation has become a top priority. Industrial turbines, especially when integrated with advanced technologies, have proven to be an essential component in achieving higher energy efficiency in power plants.

The Importance of Energy Efficiency in Power Generation

Energy efficiency is a key factor in power generation, as it directly impacts operational costs, fuel consumption, and environmental emissions. Higher efficiency means that more electricity can be generated using less fuel, which not only reduces operating expenses but also lowers carbon dioxide and other greenhouse gas emissions. Power plants worldwide are under increasing pressure to meet stringent environmental regulations while maintaining profitability. In this context, industrial turbines have emerged as a vital solution for enhancing energy efficiency.

How Industrial Turbines Enhance Efficiency

1. Combined Cycle Power Plants

One of the most significant ways industrial turbines improve energy efficiency is through combined cycle power plants (CCPP). In these systems, a gas turbine generates electricity and produces hot exhaust gases. Instead of being wasted, the exhaust heat is used to produce steam, which drives a steam turbine for additional electricity generation. This process can increase overall efficiency to 60% or more, compared to 35-40% for traditional single-cycle plants.

2. Waste Heat Recovery

Industrial turbines can also be paired with heat recovery systems to capture and reuse waste heat from the exhaust. This approach is commonly used in cogeneration or combined heat and power (CHP) plants, where both electricity and thermal energy are produced simultaneously. By utilizing waste heat, power plants can significantly reduce energy losses and improve overall system efficiency.

3. Advanced Materials and Design

Modern industrial turbines incorporate advanced materials and aerodynamic designs that allow them to operate at higher temperatures and pressures. These improvements lead to better thermal efficiency, meaning more energy is extracted from the fuel used. Additionally, the use of custom industrial turbine solutions allows power plants to optimize their turbines for specific operational conditions, further enhancing performance and efficiency.

4. Variable Load Operation

Industrial turbines are designed to handle variable load conditions, making them ideal for power plants that need to respond to fluctuating energy demand. Unlike older technologies that operate efficiently only at full load, modern turbines maintain high efficiency even at partial loads. This flexibility is crucial for balancing supply and demand in today’s dynamic energy markets.

Benefits of Improved Efficiency

- Lower Fuel Costs: Higher efficiency means less fuel is needed to generate the same amount of electricity, resulting in significant cost savings over time.

- Reduced Emissions: More efficient turbines burn less fuel and produce fewer emissions, helping power plants meet environmental regulations and reduce their carbon footprint.

- Increased Competitiveness: Power plants with higher efficiency can offer electricity at lower prices, giving them a competitive edge in the energy market.

- Enhanced Reliability: Advanced industrial turbines are built for durability and performance, reducing downtime and maintenance costs.

Custom Industrial Turbine Solutions for Maximum Efficiency

Every power plant has unique operational requirements, and one-size-fits-all solutions may not always be ideal. This is where custom industrial turbine solutions come into play. By tailoring turbine design, materials, and configurations to the specific needs of a plant, manufacturers can help operators achieve optimal performance and efficiency. Customized solutions can also extend the lifespan of turbines, improve reliability, and lower maintenance costs.

Future Trends in Industrial Turbine Technology

As the energy landscape continues to evolve, industrial turbine technology is also advancing. Innovations such as advanced digital controls, real-time monitoring, and predictive maintenance are making turbines more efficient and easier to manage. Additionally, the integration of renewable energy sources with turbine-based power plants is opening new avenues for hybrid systems that offer even greater efficiency and flexibility.

Conclusion

Industrial turbines are at the heart of energy-efficient power generation. Through combined cycle systems, waste heat recovery, advanced materials, and custom solutions, they enable power plants to produce more electricity with less fuel and lower emissions. As technology continues to advance, the role of industrial turbines in shaping a sustainable and efficient energy future will only grow. Whether through standardized models or custom industrial turbine solutions, these machines will remain a cornerstone of modern power plants, helping meet the world’s energy needs while minimizing environmental impact.