Heat pumps are essential in maintaining comfortable temperatures in our homes and offices year-round. Whether warm or cool air, these systems work tirelessly to ensure optimal indoor conditions. But what happens when they start to falter? Heat pump repair costs can add up quickly, not to mention the disruption caused by a malfunctioning system. Regular lubrication is one of the simplest yet most overlooked ways to prevent such issues. This blog dives into the importance of lubrication for your heat pump, how it impacts performance, and practical steps to ensure your system operates efficiently.

How Heat Pumps Work and Why Lubrication Matters

To appreciate the value of regular lubrication, it is vital to understand the basic mechanics of a heat pump. A heat pump transfers heat from one location to another, usually moving warm air during winter and cold air during summer. This process involves several moving parts, including the compressor, fans, and motor bearings. These components work in unison to maintain consistent airflow and temperature.

However, continuous motion creates friction. Without proper lubrication, the parts can wear down over time, leading to inefficiency and eventual mechanical failure. This is where the importance of regular lubrication truly comes into play. Addressing friction and minimizing wear prolongs the life of critical components, reducing the chances of needing heat pump repair.

Identifying Signs Your Heat Pump May Require Lubrication

Neglecting lubrication can result in several telltale signs of wear and tear. Here are some common symptoms of an improperly maintained heat pump.

Unusual Noises

Heat pumps are designed to run relatively quietly. If you begin to hear grinding, squeaking, or rattling noises, it is often a sign that the moving parts are struggling due to insufficient lubrication.

Reduced Efficiency

When essential components are starved of lubrication, friction increases, placing extra strain on the system. This often results in a noticeable decrease in heating or cooling efficiency.

Sudden Mechanical Failures

Failures in the compressor or motor can occur when parts are overworked and wear out prematurely. If these components fail, heat pump repair becomes unavoidable.

If you suspect your system is not running as smoothly as it should, lack of lubrication could be the root cause.

Benefits of Regular Lubrication in Avoiding Heat Pump Repairs

Regular lubrication provides numerous benefits that contribute to the longevity and efficiency of your heat pump. Here’s why this simple task is so vital:

First and foremost, lubrication minimizes friction. By reducing friction between parts, you are enabling the heat pump to operate more smoothly, lowering stress on its various mechanisms. Lesser strain on the parts directly results in a reduction of wear over time.

Next, lubrication contributes significantly to energy efficiency. A well-lubricated heat pump consumes less energy to perform the same functions than a system where components grind against each other. Lower energy consumption benefits the environment and leads to lower utility bills.

Finally, regular maintenance, such as lubrication, dramatically reduces the need for heat pump repair. Addressing wear and tear early prevents larger, more expensive failures in the future, which could require parts replacement or a full system overhaul.

When and How to Lubricate Your Heat Pump Components

Contrary to what many people believe, lubricating your heat pump does not necessarily require professional intervention each time. There are simple steps homeowners can follow to keep their system running efficiently. The key, however, is to ensure you understand which parts require lubrication and how often this should be done.

Specific components, like the motor bearings and fan blade, require lubrication more frequently because of their constant motion. Most manufacturers provide clear recommendations in the heat pump’s user manual regarding lubrication schedules and types of lubricants to use. Generally, applying lubrication once or twice a year is sufficient, often before the onset of winter or summer when the system will be used most.

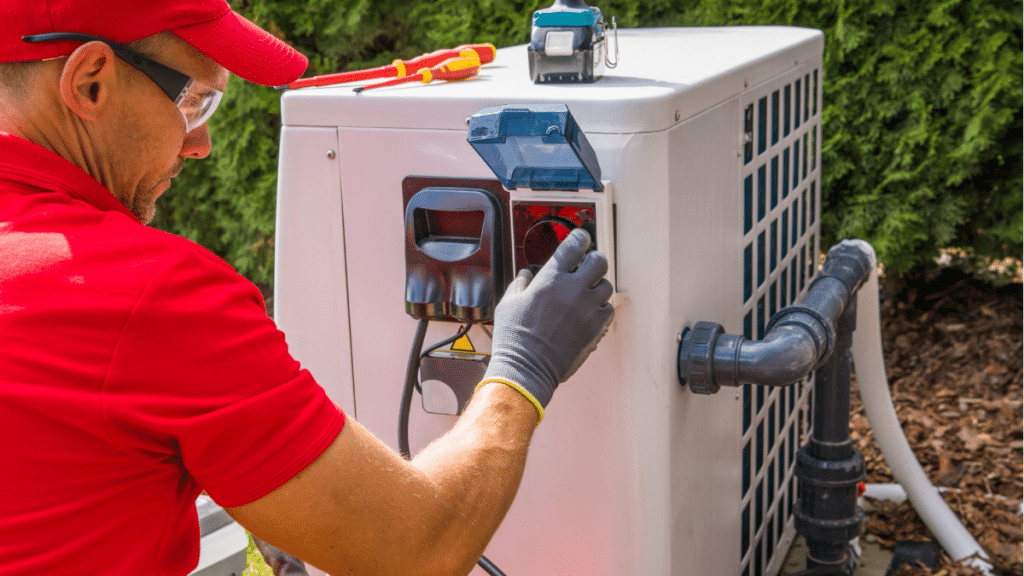

To get started, turn off your heat pump completely and ensure it is disconnected from its power source. Then, locate the components requiring lubrication, such as the motor bearings or condenser fan. Wipe away any old lubricant and grime before applying fresh lubricant evenly across the areas in question.

Remember to consult a professional technician when working with more complex systems. This ensures that there is no risk of over-lubrication or accidentally damaging your system.

Professional Maintenance vs DIY Lubrication

While routine lubrication is a task many homeowners can handle, professional servicing offers a more thorough solution. A trained technician can inspect your heat pump, catching potential problems early—something a DIY job might overlook. Hiring professionals also means having access to specialized tools and high-quality lubricants, which can make a massive difference in performance. Periodic professional maintenance prevents heat pump repair and ensures the overall health of your entire HVAC system.

Start Protecting Your Heat Pump Now

Maintaining your heat pump through regular lubrication is one of the simplest ways to ensure long-term efficiency and avoid costly repairs. By following routine lubrication schedules and trusting professional technicians for periodic servicing, you will significantly reduce the likelihood of breakdowns and prolong the lifespan of your system.

If you are concerned about your heat pump’s current performance or want to prevent future heat pump repair, schedule a maintenance check with a trusted HVAC professional today. Taking action now will secure your comfort (and your wallet) in the years ahead.