CNC prototype machining (Computer Numerical Control machining) is a key technological tool in modern manufacturing, widely used in industries including automotive, medical, and electronics. By precisely controlling machine tools through computers, CNC technology makes it possible to quickly and accurately produce complex components.

As technology continues to advance, CNC rapid prototyping plays an increasingly crucial role in product development, design verification, and customized production, helping enterprises improve production efficiency, shorten R&D cycles, and reduce manufacturing costs.

This guide will present a comprehensive overview of CNC prototype machining, helping you understand how it enhances the product development process.

What is CNC Prototype Machining?

CNC rapid prototyping harnesses the operations of mills and drills by offering computer control of digitized designs like the CAD files used in creating precise parts of the final product.

CNC prototype machining can be precise, generally up to micrometers, thus applicable in functional testing and production of quality prototypes. In contrast, CAD-informed 3D printing has lower accuracy and comparatively coarser surfaces than injection-molded parts. As a result, they are less suitable for functional parts, while they are fine for aesthetic prototypes. Besides, the injection molding technique is right for volume production. Nonetheless, it is expensive and impractical to construct single samples.

In addition, rapid CNC prototyping can process various materials, like metal and plastic, to create more durable and structurally stable prototypes, while the material choices for 3D printing are limited and less intense. Injection molding is suitable for mass production, but it requires the prior manufacture of molds for prototyping, which can be costly.

How CNC Prototype Machining Works

CNC prototype machining transforms digital designs into high-precision physical parts through a series of precise steps, ensuring that the final product satisfies design requirements and possesses the necessary functionality and quality.

1. CAD Design Creation

Designers produce detailed models of parts or prototypes with the help of computer-aided design (CAD) resources. Such design drawings contain all dimensions, shapes, and any other detail that can help in achieving the intended design of the product.

2. Conversion to Machine-Readable G-code

After the CAD design is completed, the design is translated to G-code which is another form of programming language that serves to program the CNC machines. For instance, G-code specifies such parameters as tool movement path, cutting speed, and feed rate.

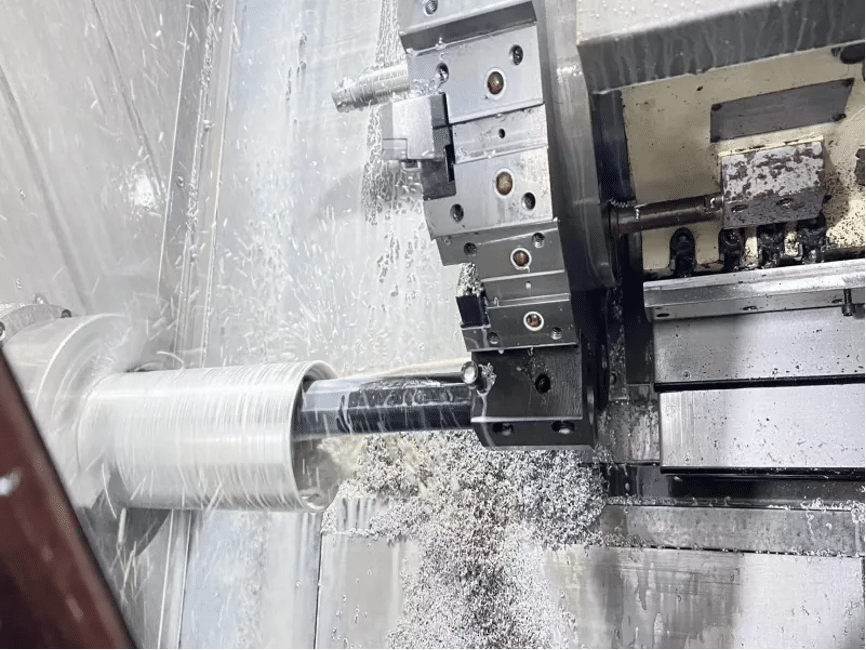

3. Machining Process

CNC machine tools carry out actual machining process operations using G-Code. These operations include:

∙ Milling is the process of cutting material using a rotating tool, and it is used to cut flat surfaces, grooves, or designs.

∙ Turning involves the removal of excess material from a rotating workpiece using a cutting tool primarily employed for creating circular or shaft-like components.

∙ Drilling refers to the creation of holes in a workpiece using a drill bit, suitable for various hole sizes and depths.

4. Post-Processing and Quality Checks

After machining, some post-processing steps are usually required, such as deburring, polishing, or coating, to ensure the surface quality and functionality of the parts. Meanwhile, quality inspections are conducted to ensure that the prototype meets design specifications, checking dimensions accuracy and surface smoothness to guarantee the quality of the final product.

Advantages of CNC Prototype Machining

Due to its unique advantages, CNC prototyping has been applied essentially in manufacturing industries so as to develop high-quality prototypes with ease. Key advantages include:

1. Precision and Accuracy

Compared to other types of prototyping, CNC prototype machining can give high precision and consistency that are as good as the micron levels. Therefore, this manufacturing process is ideal when developing parts with specific modalities; each prototype in production meets the proposed design and minimizes mistakes.

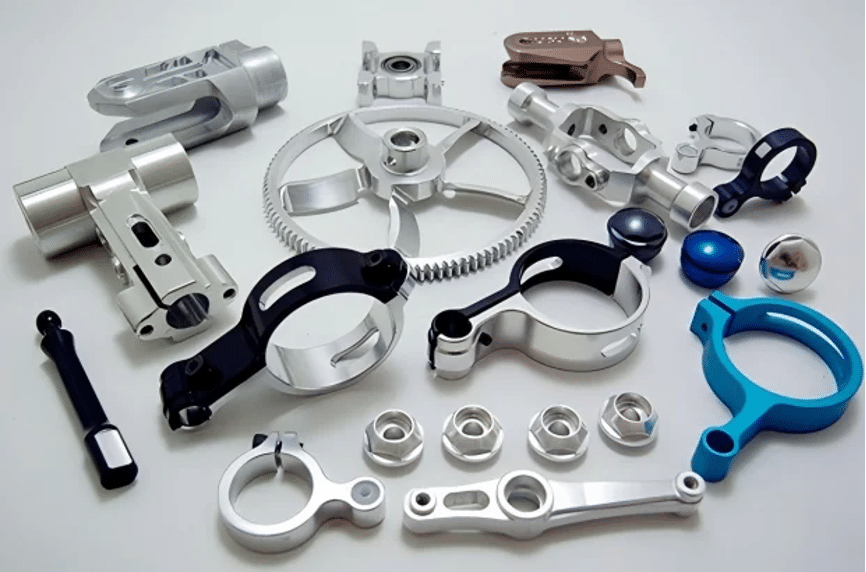

2. Material Versatility

CNC machining cuts and shapes an extensive array of materials, like metals, plastics, and composites. Whether it is substantial metallic parts or elastic-plastic parts, prototype CNC machining can offer suitable operations.

3. Speed and Efficiency

While CNC prototype machining is program-controlled, the level of automation makes it much faster than conventional prototype machining. Therefore, in addition to saving processing time, CNC machines deliver superior quality, distinguishing them from traditional manual methods.

4. Cost-Effectiveness

CNC prototyping is well suitable for small batch production since it is cost-effective. However, while it may cost a lot of money to set up the equipment needed for CNC at first, this approach may actually lower unit cost in the long run since the CNC prototype machining process tends to reduce manual interference as well as the processing time.

5. Functional and Durable Prototypes

Since CNC machining can work with rugged materials and produces sturdy parts, the prototypes are highly wear-resistant and capable of testing the product’s functionality.

Real-World Applications of CNC Prototype Machining

By adopting CNC prototype machining, industries can create highly accurate prototypes that facilitate product development, testing, and market launch.

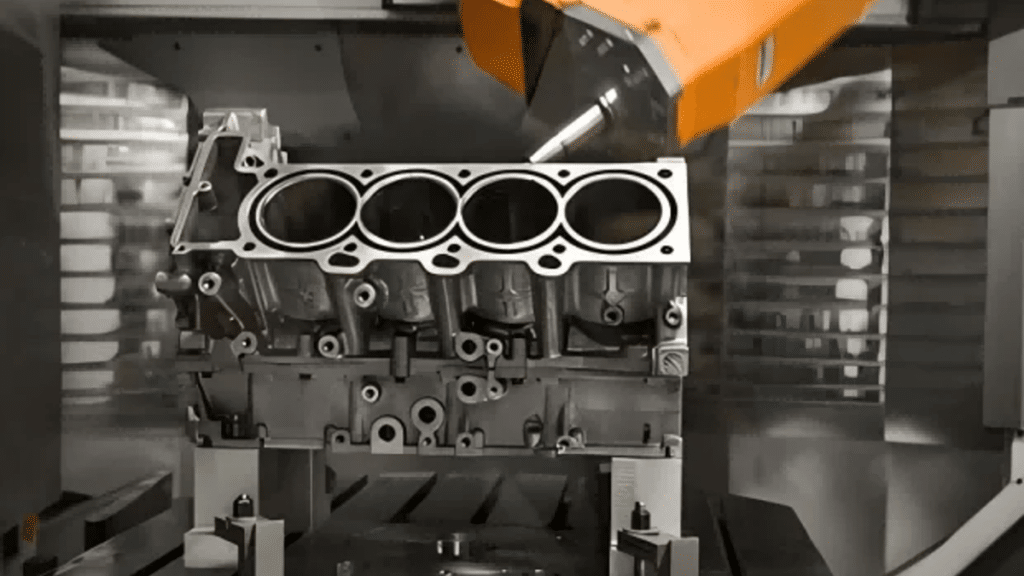

1. Automotive Industry

In automotive applications, CNC prototype machining has been widely used to manufacture engine blocks, body panels, and transmission systems, ensuring that each part meets the requirements for high precision and complex shapes.

2. Medical Sector

CNC machining is also widely used in the medical field, where components, such as implants, surgical instruments, and artificial body parts (like joints and teeth), require zero tolerance for errors.

3. Electronics

In the manufacturing of electronics products, CNC machining is used in the creation of products such as housings, connectors, and heat sinks to enhance the dimensions and assembly tolerance of the final product.

4. Aerospace, Robotics, and Consumer Products

CNC prototype machining is especially adopted by industries like aerospace, robotics, and consumer electronics for complex and robust products such as robotic arms and smart devices. In this way, it contributes to fast development and testing, and optimizing the product designs.

APT Mold: Your Trusted Partner for CNC Prototype Machining

When choosing CNC prototyping services, it is crucial to find the right partner. A professional machining factory will ensure the development of a quality prototype with the best optimization for its cost, time, and performance.

APT Mold, established in 2017, specializes in rapid prototyping and delivers high-quality prototypes for various industries, serving as an excellent partner for your manufacturing.

State-of-the-Art Manufacturing Facilities

APT, trusted by 300+ companies globally, features a 1,600 m2 facility and a team of 150 employees. With over 4,000 projects delivered, we provide customized services, supporting clients from product development to mass production.

Experienced Technical Support

Our skilled engineers analyze your part geometry for rapid CNC prototyping, identifying challenges and providing innovative solutions for smooth production.

Strict Quality Control

APT ensures strict quality control in CNC prototype machining, from material verification to final inspection. Our ISO 9001:2015 and IATF 16949:2016 certifications guarantee top-quality parts meet all regulatory and performance standards.

Unlock the Potential of CNC Prototype Machining for Your Business

CNC prototype machining offers high precision, fast delivery, and a variety of material options, widely used in medical, automotive, and other related industries.

If you’re looking for a CNC prototype service that understands your business needs, APT Mold is here to deliver excellence. Explore APT-Mold’s custom CNC services for your business success today!