Industrial storage tanks play a critical role in numerous sectors, serving as essential infrastructure for storing liquids, chemicals, and other materials. These robust containers are fundamental to modern industrial processes, providing safe and efficient storage solutions across various industries.

Understanding Industrial Storage Tanks: An Overview

Industrial storage tanks are specialized containers designed to hold substantial quantities of liquids, gases, and other substances under controlled conditions. These tanks are engineered with precision to withstand diverse environmental conditions, chemical interactions, and specific industry requirements.

Historical Context and Evolution

The development of storage tanks dates back to the industrial revolution, where primitive metal and wooden containers were first used for storing essential resources like water, oil, and chemicals. Over time, technological advancements have transformed these basic containers into sophisticated engineering marvels with advanced materials, intricate design features, and enhanced safety mechanisms.

Types of Industrial Storage Tanks

Different industries require specialized types of industrial storage tanks to meet their unique storage needs. Understanding these variations is crucial for selecting the most appropriate solution.

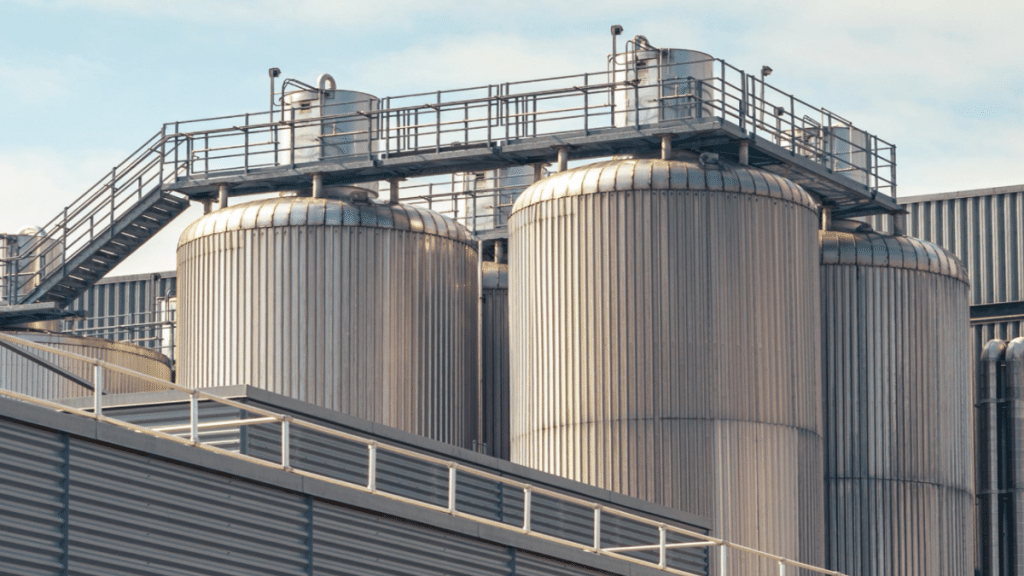

1. Vertical Cylindrical Tanks

These tanks are the most common type of industrial storage containers. Characterized by their vertical orientation and cylindrical shape, they are ideal for storing large volumes of liquids and are widely used in petrochemical, agricultural, and manufacturing sectors.

2. Horizontal Storage Tanks

Horizontal tanks are preferred in situations with space constraints or specific spatial requirements. They are commonly used in transportation, mobile applications, and industries where horizontal installation provides better functionality.

3. Floating Roof Tanks

Designed to minimize vapor loss and reduce environmental contamination, floating roof tanks feature a movable roof that rises and falls with the liquid level. These tanks are predominantly used in petroleum and chemical industries.

4.Underground Storage Tanks

Primarily used for storing fuel, chemicals, and water, underground tanks offer protection from environmental factors and help conserve surface space. They require specialized construction and rigorous water tank inspection and maintenance tips to ensure long-term integrity.

Materials and Construction

Modern tank manufacturers utilize advanced materials to enhance tank performance and durability. Common materials include:

- Carbon Steel: Excellent for general industrial applications

- Stainless Steel: Superior corrosion resistance

- Fiberglass Reinforced Plastic (FRP): Lightweight and chemically resistant

- Polyethylene: Ideal for water and non-corrosive liquid storage

Key Applications Across Industries

Petrochemical Sector

Storage tanks are crucial for storing crude oil, refined petroleum products, and various chemical compounds. They facilitate efficient inventory management and transportation logistics.

Agriculture

Agricultural storage tanks are essential for maintaining water supplies, storing fertilizers, pesticides, and supporting irrigation systems.

Manufacturing

Industrial manufacturers use storage tanks for holding raw materials, coolants, lubricants, and waste management solutions.

Safety and Maintenance Considerations

Proper maintenance of industrial storage tanks is paramount to prevent leaks, contamination, and potential environmental hazards. Regular inspections, corrosion monitoring, and adherence to industry standards are critical for ensuring tank longevity and operational safety.

Inspection Protocols

Routine inspections should include:

- Structural integrity assessment

- Corrosion evaluation

- Leak detection

- Material thickness measurement

- Protective coating examination

Environmental and Economic Benefits

Modern storage tanks contribute significantly to environmental sustainability and economic efficiency. They help:

- Minimize product waste

- Reduce environmental contamination risks

- Optimize resource management

- Enhance industrial process efficiency

Conclusion

Industrial storage tanks represent a sophisticated intersection of engineering, material science, and industrial design. As technology continues to evolve, these critical infrastructure components will become increasingly efficient, sustainable, and adaptable to emerging industrial challenges.

Understanding the nuanced requirements of different storage tank types empowers industries to make informed decisions, ultimately driving innovation and operational excellence.