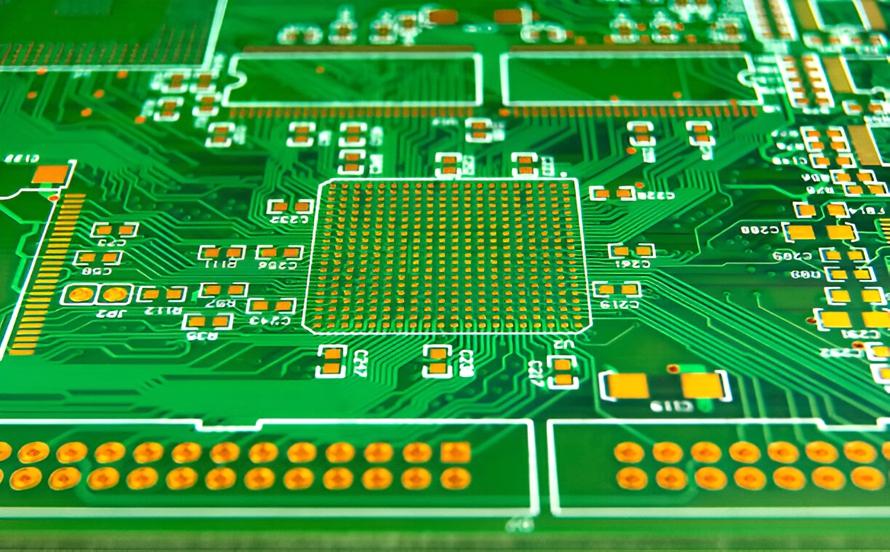

BGA assembly, or Ball Grid Array assembly, is a highly advanced method used in electronics manufacturing to mount integrated circuits onto printed circuit boards. Instead of relying on traditional leads or pins, BGA packages use an array of tiny solder balls placed on the underside of the chip. These solder balls act as both the physical connection and the electrical pathway between the component and the circuit board.

This assembly method has become an industry standard for complex devices such as processors, memory chips, and high-performance controllers. BGA assembly allows manufacturers to pack more power into smaller spaces, making it a key technology in modern electronics.

Advantages of BGA Assembly

BGA assembly offers numerous benefits over older packaging methods. One of the main advantages is better electrical performance. With shorter and more uniform connections, BGA packages reduce inductance and resistance, which improves signal integrity. This is especially critical in devices that require fast processing and stable communication.

Another major benefit is improved thermal performance. Since the solder balls are distributed across the entire bottom surface of the package, heat dissipation is more effective. This prevents overheating and extends the life of both the component and the overall device. Additionally, BGA assembly provides higher packaging density, allowing for compact and lightweight devices without compromising performance.

Challenges in BGA Assembly

Despite its advantages, BGA assembly comes with challenges that require advanced equipment and expertise. The biggest challenge is inspection. Unlike traditional leads that are visible from the sides, BGA connections are hidden underneath the component. This makes visual inspection impossible. Manufacturers rely on X-ray inspection and automated testing systems to detect solder defects such as voids, bridging, or insufficient connections.

Another challenge is rework and repair. If a BGA joint fails, it is much harder to remove and replace the component compared to traditional packages. Specialized tools and highly skilled technicians are required to ensure proper reflow and alignment during rework.

The Process of BGA Assembly

The BGA assembly process begins with careful PCB design, where pad size, solder mask, and thermal reliefs are optimized for the BGA footprint. During assembly, solder paste is applied to the pads using a stencil, followed by precise placement of the BGA component with pick-and-place machines.

Once placed, the board undergoes reflow soldering in a controlled oven. The heat causes the solder balls to melt and form solid connections between the package and the PCB pads. After cooling, the assembly is inspected using X-ray technology to verify the integrity of each solder joint. This ensures that the final product is both reliable and durable.

Applications of BGA Assembly

BGA assembly is widely used in industries that require compact, powerful, and reliable electronics. In consumer electronics, it is used for processors in smartphones, tablets, and laptops. In networking equipment, BGAs are used for high-speed communication chips and controllers. Automotive systems also rely on BGA assembly for advanced driver assistance systems, infotainment units, and engine control modules.

In aerospace and defense, BGA assembly plays a critical role in mission-critical systems where reliability and precision are essential. Medical devices such as imaging equipment and portable diagnostic tools also benefit from the compactness and efficiency provided by BGA packaging.

Why Quality Matters in BGA Assembly

Since BGA connections are hidden and not easily accessible, quality in BGA assembly is crucial. Even a single faulty connection can lead to device failure or performance issues. To maintain high standards, manufacturers use advanced inspection methods, automated optical systems, and strict testing protocols.

Quality BGA assembly ensures that the device can perform under various operating conditions, including high temperatures, vibration, and heavy usage. This makes it vital for manufacturers to partner with experienced assemblers who can deliver precision and reliability at scale.

Future of BGA Assembly

As devices become more powerful and compact, the demand for advanced BGA assembly is expected to grow. With the rise of artificial intelligence, 5G networks, and high-performance computing, BGA packaging will continue to evolve. Future developments may include finer ball pitches, advanced materials for heat management, and improved rework solutions. Automation and AI-driven inspection tools will also enhance the accuracy and efficiency of BGA assembly.

Conclusion

BGA assembly is at the heart of modern electronics, enabling powerful, compact, and efficient devices across industries. Its unique design and advantages make it indispensable for applications where reliability and performance are non-negotiable.

If your business is looking for expert solutions, working with an experienced printed circuit board assembler ensures that your BGA assembly projects meet the highest standards of precision, reliability, and performance.