You might be familiar with the aseptic packaging process. It is a process in which food, pharmaceutical, or other content are sterilized separately from packaging. After sterilizing, the contents are inserted into the container. This preserves the freshness of the product to be preserved. If you want to learn more about the aseptic filling line, then you’ve come to the right place as I have compiled an ultimate guide to know about Aseptic filling lines. Let’s get started.

What is an aseptic filling line?

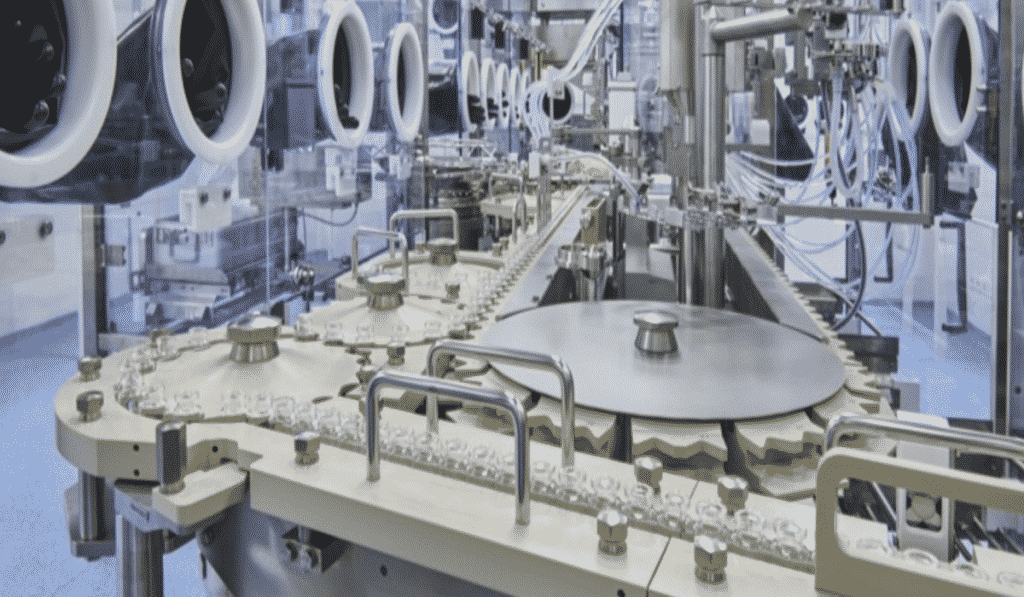

The aseptic filling line is efficient to keep the container, environment, and product sterile throughout the bottling process. Aseptic filling line holds an important place in the beverage industry. The primary purpose of Aseptic packaging is to prevent microorganisms from entering a package during the package or even after the packaging. The aseptic filling line can be divided into five types, which are as follow:

- Fill and seal type

- Form, fill, and seal type

- Erect, fill, and seal type

- Thermoform, fill, seal type

- Blow mold, fill, and seal type

The type of material used for the container depends on the product that is to be stored, i.e., different containers are used to store liquid food products, medicines, vaccines, etc.

Aseptic filling equipment history

The first Aseptic machine was developed around 1927. A brief timeline of Aseptic filling equipment is given below for your consideration:

– Olin Ball in 1927 developed the Heat-cool-fill (HCF) machine

– Avoset process was developed in the 1940s by George Grindrod

– Roy Graves, in the 1940s, started sterilizing milk

– In the late 1940s, Dole Martin developed the Dole Aseptic process

– In 1962, Tetrahedron was introduced by Tetra Pak

– The use of hydrogen peroxide was approved by FDA in 1981

The development trend of aseptic filling technology

The advancement of the aseptic filling technique has been a steady process. Numerous researchers and firms have contributed to the advancement of aseptic filling technology since the introduction of the first aseptic machine in 1927. As a result of which, today, we have the most aseptic filling machines ever. The ultimate objective is to develop an aseptic filling process that is cost-effective, efficient, and reliable. Due to the advanced application of aseptic filling technology, aseptic filling technology will play an increasingly important role in the future.

Applications of aseptic filling line

The aseptic filling line is designed to handle a range of containers. Aseptic packaging is used to store food items, medicines, beverages, and liquids such as milk, juice, tea, energy drinks, pudding, soup, eye drops, disposable syringes, etc. Hence aseptic filling line is extensively used in the packaging industry. Let’s move ahead, and let me tell you the benefits of an aseptic filling line.

Benefits of aseptic filling

An aseptic filling line has several advantages, which is why it is so popular in the packaging industry. Some of the major benefits of aseptic filling include:

- Extended shelf life

- Hygiene

- Preservation of food

- Convenient storage

- Easy to handle, resealable, and durable

- Eco-friendly

Tech-Long aseptic filling line and its advantages

I think you’re interested in purchasing an aseptic filling line but haven’t found a reputable provider yet. Don’t worry, and you’ve come to the right location. That’s correct. Tech-Long is a qualified manufacturer and distributor of aseptic filling lines. We are proud of Tech-Long’s aseptic filling line, which has a long life span at ambient temperature. Some of the benefits of Tech-Long’s aseptic filling line are as follow:

- Hygiene.

- Wide range of applications. It can be used to fill all types of liquid beverages, such as tea, juice, energy drinks, protein-based beverages, milk-based beverages, and so on.

- Cost-saving.

- Various packaging container designs are available.

- Contaminants are kept away, so safe preservation is ensured.

Conclusion

Tech-Long, which was founded in 1998, is one of the leading providers of aseptic filling systems. Tech-Long has amassed a wealth of expertise over the years and is an expert in all industrial processes. Their track record in the development of intelligent packaging technologies is unrivaled. They manufacture a variety of systems in addition to aseptic bottle filling systems, including water and beverage treatment systems, conveying series, labeling series, intelligent workshops, and so on. They can manufacture high-quality smart packaging solutions thanks to their smart packaging technology. Please do not hesitate to contact them for more details right away.