Key Takeaways

- Industrial control transformers are essential for voltage regulation in manufacturing equipment.

- They enhance operational safety by isolating control circuits from main power supplies.

- Applications span across machine tools, conveyor systems, assembly lines, and more.

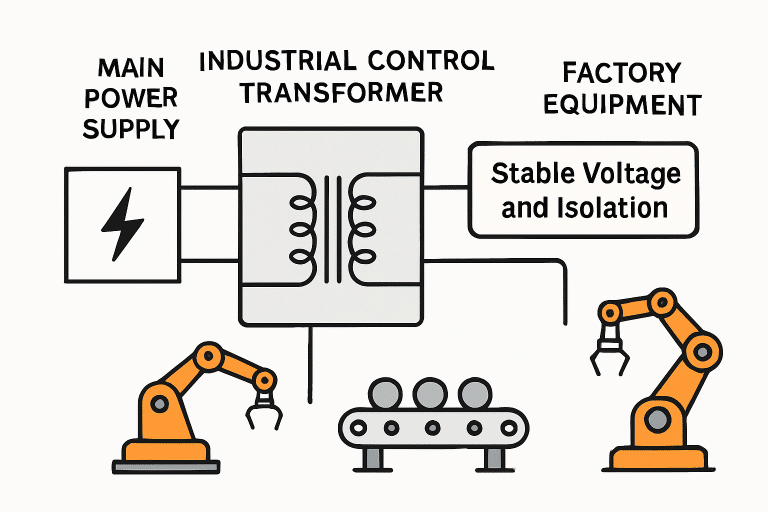

As manufacturing industries evolve to adopt more automation and precision-driven processes, the importance of stable and reliable electrical systems becomes paramount. Industrial control transformers are central to this reliability, offering the steady voltage and circuit isolation necessary for modern machinery to function consistently and safely.

These transformers play a crucial role in safeguarding the control circuits from unpredictable fluctuations in the main power supplies. By ensuring only stable power reaches essential systems, they not only prolong equipment life but also minimize malfunctions that could lead to costly downtime and safety risks on the factory floor.

Manufacturing operations now rely on an interconnected network of automated systems—from assembly robots to programmable logic controllers (PLCs)—demanding high precision and coordination. Industrial control transformers underpin these processes by supplying current at the correct voltage, which is critical for smooth operation and maximum productivity in environments where even minor disruptions can result in significant production losses.

Furthermore, the isolation provided by these transformers enhances both system safety and compliance with industry standards, offering peace of mind for operations managers responsible for maintaining safe working conditions and meeting rigorous regulatory requirements.

For additional insights into industrial electrical standards, refer to authoritative resources like the National Electrical Manufacturers Association (NEMA).

Machine Tool Operations

Industrial control transformers are indispensable in machine tool environments, where equipment such as CNC machines, lathes, and robotic arms must operate with exacting precision. The transformers deliver the constant, regulated voltage required not just for machine function but for accurate, repeatable performance. Voltage fluctuations can compromise production quality or damage sensitive electronics, but using control transformers mitigates these risks.

Conveyor and Material Handling Systems

Conveyor belts and other material handling systems form the backbone of modern production plants. These systems rely on the uninterrupted performance of PLCs, sensors, and motorized drives—each of which is reliant on a stable electrical supply from industrial control transformers. Consistent voltage reduces the likelihood of unexpected stoppages, which can otherwise halt entire production lines and lead to inefficiencies or safety issues.

Automated Assembly Lines

As assembly lines become more automated, industrial control transformers ensure that critical components—such as actuators, relays, and solenoids—operate without disruption. Reliable power is crucial for achieving high throughput speeds, minimizing downtime associated with power issues, and helping industries stay competitive by maximizing uptime and production yields. This operational stability has a direct impact on quality assurance and customer satisfaction.

Packaging Equipment

Packaging is often the final step between production and distribution, requiring high-speed, reliable, and coordinated systems. Automated sealers, wrappers, and labelers use control transformers to maintain accurate timing and sequencing. This not only boosts productivity but also helps reduce material waste, as fewer packages are finished incorrectly due to voltage-induced equipment misfires.

HVAC and Environmental Control Systems

Maintaining environmental parameters—such as temperature, humidity, and air quality—is essential for both product consistency and employee comfort. Industrial control transformers ensure HVAC systems operate smoothly, adjusting conditions to meet the unique requirements of each manufacturing process and supporting regulatory compliance in sensitive applications such as food production or electronics manufacturing. According to the U.S. Department of Energy, efficient HVAC operations are critical to reducing operational costs and energy consumption.

Lighting and Alarm Systems

Safety is fundamental in all manufacturing environments. Control transformers power both routine and emergency lighting systems, as well as integrated alarm circuits that provide immediate notification during hazardous events. Their reliability ensures these systems perform as expected, improving workplace safety and enabling rapid response to incidents when seconds count.

Welding Equipment and Heavy Machinery

Heavy machinery, including industrial welding stations, places significant demands on power supply infrastructure. Industrial control transformers help stabilize voltage levels for these high-load applications, preventing equipment from short-circuiting or malfunctioning. The result is improved operational consistency, reduced repair costs, and enhanced safety for operators working with potentially dangerous equipment.

Advantages of Using Control Transformers in Manufacturing

- Improved Equipment Longevity: By delivering a stable voltage, industrial control transformers reduce component wear and stress, extending the life expectancy of even sensitive electronics and motors.

- Reduced Downtime and Maintenance: Reliable performance translates into fewer unexpected breakdowns, less unscheduled maintenance, and a smoother production process with maximum up-time.

- Enhanced System Safety and Energy Efficiency: These transformers not only protect workers by isolating hazardous voltages but also help facilities meet growing energy efficiency goals, supporting sustainability and cost-saving initiatives.

Conclusion

Industrial control transformers are critical to the foundation of dependable, high-output manufacturing operations. Their presence supports the seamless functioning of machine tools, material transport, assembly, and safety systems, while also contributing to energy efficiency and a safer workplace. As the demands on manufacturing facilities grow, so does the essential role that industrial control transformers play in ensuring quality, safety, and productivity at every stage of the production process.