Properly selected chemical hazard signage is a key part of protecting workers from chemical exposure incidents. It’s also a necessity when it comes to meeting stringent regulatory requirements.

According to OSHA and HSE statistics, chemical exposures account for many thousands of workplace injuries annually across the US and UK, many of which could be prevented through more effective hazard communication. Worker safety isn’t just corporate responsibility, it has financial consequences when accidents occur – not least in staff turnover and lack of confidence, but also insurance and legal fees.

Non-compliant signage can also result in substantial fines and operational shutdowns under both OSHA regulations and UK COSHH (Control of Substances Hazardous to Health) requirements. The stakes are simply too high to approach chemical hazard signage best practices as an afterthought.

When choosing chemical signage for your facility, the decision isn’t just around basic warning labels. Today’s industrial spaces demand sophisticated signage solutions that integrate with comprehensive safety management systems, somewhat like the broader workplace safety frameworks discussed in modern health and safety management approaches.

Material selection and durability considerations

The foundation of choosing chemical hazard labels is all about materials that can withstand the harsh conditions typical of chemical storage and handling areas – these aren’t docile conditions. PVC signs offer good chemical resistance and cost-effectiveness for most indoor applications, though it’s worth remembering aluminum has better durability for outdoor installations or high-traffic areas where impact resistance is crucial.

Photoluminescent materials represent the premium choice for emergency situations. These continue to glow for hours after power loss to help guide workers to safety. These materials prove particularly valuable in chemical storage facilities where emergency lighting may be compromised during big incidents. However, photoluminescent signs require regular light exposure to maintain their effectiveness and typically cost around 50% more than standard materials. In many cases, it’s worth it.

The environment should influence material selection. Facilities with high humidity and temperature fluctuations, or exposure to cleaning chemicals, need UV-stable and fade-resistant materials. Marine-grade aluminum with specialized coatings can last 15-20 years in corrosive environments, while standard PVC may degrade within 3-5 years under similar conditions.

Size, color, symbol

Facility chemical safety signs must comply with specific dimensional requirements based on viewing distances and ambient lighting conditions. Both OSHA’s Hazard Communication Standard and the UK’s Safety Signs and Signals Regulations have a similar view, and it revolves around expected average eyesight.

The general rule prescribes that sign lettering should be visible from 50 feet away, translating to minimum letter heights of 1 inch per 50 feet of viewing distance. For chemical storage areas with limited sightlines, this often means signs should feature 2-3 inch letter heights at minimum.

High-contrast color combinations keep visibility good across different lighting conditions. Red backgrounds with white text provide the strongest contrast for danger warnings, while yellow backgrounds with black text are good for caution notices.

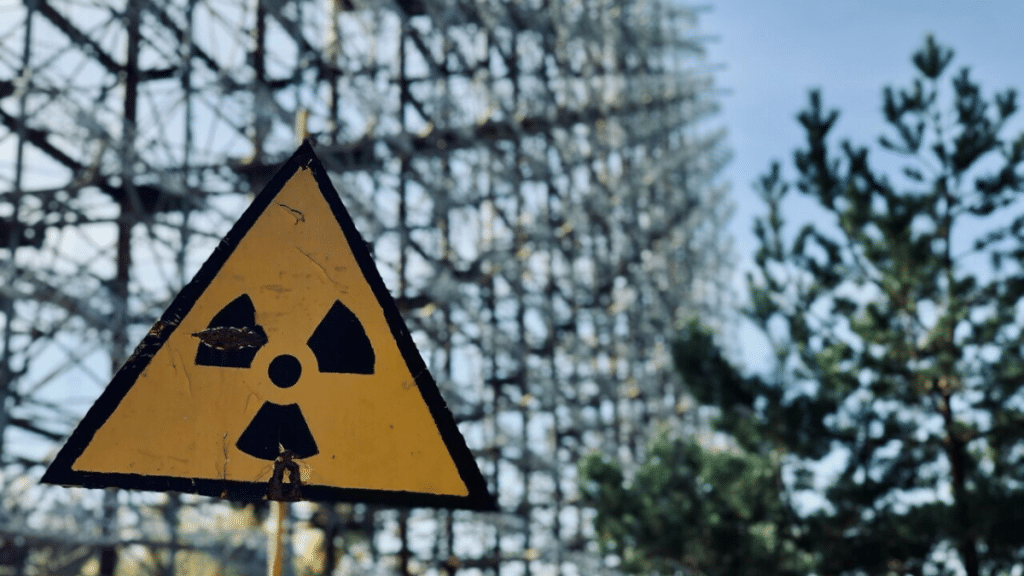

ISO 7010 chemical signs have become the global standard for consistent hazard communication, replacing older national standards with more universally recognized pictograms. These symbols eliminate language barriers and provide instant recognition for international workers. The ISO system covers over 40 chemical-specific hazards, from corrosive substances to oxidizing agents. Each has its own colors, proportions, and placement requirements. Facilities transitioning to ISO 7010 must ensure all signage meets the strict specs outlined in the chemistry standards documentation.

Strategic placement and mounting guidelines

Optimal sign placement begins with some analysis. Track worker movement patterns, sight lines and emergency egress routes for a good understanding. Signs should be positioned at eye level (approximately 60-66 inches from floor level) and perpendicular to the primary direction of approach. Corner installations often prove more effective than wall-centered placement, as they capture attention from multiple approach angles.

Mounting hardware is surprisingly important too on the sign longevity and compliance. Permanent adhesive mounting works well for smooth, clean surfaces but fails in environments with temperature cycling or moisture exposure. Mechanical fasteners are super reliable but require careful consideration of substrate materials.

Emergency lighting considerations affect both the placement and material choice. Signs near emergency exits or evacuation routes must be visible during power outages, either through photoluminescent materials or emergency lighting integration.

Common implementation mistakes to avoid

EHS professionals consistently identify three implementation failures that compromise signage effectiveness. First, incorrect height installation is still surprisingly common, with signs often placed too high or too low.

Second, fading graphics are a persistent maintenance challenge that many facilities underestimate – it adds up, too. UV exposure, chemical vapors and cleaning chemicals gradually degrade sign visibility. Facilities should establish quarterly inspection schedules and have replacement inventory when needed.

Third, inconsistent symbol usage creates confusion and reduces overall effectiveness. Mixing different pictogram standards (ISO 7010, ANSI, older national standards) within the same facility undermines the cognitive recognition benefits that standardized symbols provide.

Take the next step in optimizing your facility’s chemical safety communication. Access the complete graphical symbols reference guide to standardize your facility’s hazard communication system and protect your most valuable asset – your workforce.