For decades, the LED industry has relied on a seemingly simple approach to convert blue LED light into white: coat the LED chip with a silicone layer mixed with yellow phosphor particles. This combination works blue light excites the phosphor, producing yellow light that combines with remaining blue to create white illumination. Billions of LEDs operate on this principle today.

But there’s a fundamental problem: silicone degrades. It yellows, cracks, loses transparency, and progressively fails under the very conditions LEDs create heat, high-energy light, and continuous operation. This degradation is why LED fixtures that start bright gradually dim, why color shifts occur over time, and why promised 50,000-hour lifespans often disappoint in real-world applications.

A materials science breakthrough is changing this paradigm. Ceramiclite Fluorescent Transparent Ceramic (FTC) technology replaces vulnerable silicone with a solid ceramic phosphor layer that simply does not degrade. The implications extend far beyond incremental improvement FTC fundamentally redefines what is possible in LED reliability, efficiency, and lifespan.

The Silent Failure: Why Traditional Silicone Packaging Fails

To understand why FTC represents such a significant advancement, we must first examine why the traditional approach has inherent limitations that no amount of engineering refinement can overcome.

The Conventional LED Structure

Standard high-power white LEDs employ a layered architecture:

- LED Chip: A blue-emitting semiconductor (typically gallium nitride) that produces monochromatic blue light when energized

- Phosphor Particles: Yellow-emitting cerium-doped yttrium aluminum garnet (YAG:Ce) phosphor powder

- Silicone Matrix: Transparent silicone encapsulant mixed with phosphor particles, coating the LED chip

- Encapsulation: Additional clear silicone protecting the assembly

When blue light from the LED strikes phosphor particles suspended in silicone, a portion converts to yellow light. The combination of unconverted blue and generated yellow produces white light. By adjusting phosphor concentration, manufacturers control color temperature.

This approach works adequately for low-power, low-temperature applications. But high-power LEDs, the type used in industrial, commercial, sports, and outdoor lighting create conditions where silicone’s limitations become critical failures.

Silicone’s Fundamental Vulnerabilities

Thermal Degradation: Silicone is an organic polymer. Like all organic materials, it degrades when exposed to sustained elevated temperatures. High-power LEDs generate substantial heat, with junction temperatures commonly reaching 80-120°C and localized hot spots potentially exceeding 150°C.

At these temperatures, silicone undergoes several destructive processes:

- Chain Scission: Polymer chains break down, reducing molecular weight and mechanical strength

- Oxidative Degradation: Oxygen reacts with polymer chains, particularly at elevated temperatures

- Yellowing: Degradation produces chromophores—molecules that absorb blue and violet light, giving the silicone a yellow or brown tint

- Embrittlement: Loss of plasticizing components makes silicone brittle and prone to cracking

Research shows that silicone degradation accelerates exponentially with temperature. LED packages operating at 100°C experience degradation rates 5-10 times faster than those at 60°C.

Photochemical Degradation: Beyond thermal stress, silicone suffers from photo-oxidation. High-energy blue and UV light from LEDs contains sufficient energy to break chemical bonds in silicone:

- Blue light (450nm wavelength) carries 2.75 eV of energy per photon

- UV light carries even more energy

- This continuous high-energy photon bombardment cleaves silicone molecular bonds

- Free radicals form and trigger cascading degradation reactions

The irony is brutal: the very light the LED produces destroys the material meant to protect it.

Moisture Intrusion: Silicone is permeable to moisture. Water molecules can diffuse through silicone over time, reaching the LED chip and phosphor particles:

- Water accelerates corrosion of metal contacts and wire bonds

- Moisture causes phosphor particles to agglomerate, reducing efficiency

- Water acts as a reactant in oxidative degradation of silicone itself

- Freeze-thaw cycles in outdoor applications create mechanical stress

Even in “sealed” LED packages, moisture gradually accumulates through silicone permeation, particularly in humid or outdoor environments.

Coefficient of Thermal Expansion Mismatch: Silicone expands and contracts significantly with temperature changes (CTE: ~300 × 10⁻⁶ /°C), while LED chips and substrates expand much less (CTE: 3-7 × 10⁻⁶ /°C for ceramics, ~23 × 10⁻⁶ /°C for aluminum).

This massive mismatch creates mechanical stress at interfaces during every heating/cooling cycle:

- Stress concentrates at chip edges and wire bond connections

- Repeated cycling causes crack initiation and propagation

- Cracks allow moisture ingress and accelerate degradation

- Delamination occurs between silicone and chip surfaces

Fixtures undergoing frequent on/off cycles or experiencing large ambient temperature swings suffer particularly severe degradation.

Phosphor Settling and Non-Uniformity: Phosphor particles suspended in liquid silicone can settle before curing, creating concentration gradients. This leads to:

- Color uniformity issues between LED packages

- Inconsistent color rendering across fixture arrays

- Batch-to-batch variation in manufacturing

The Measurable Consequences

These degradation mechanisms aren’t theoretical they manifest in measurable performance decline:

Lumen Depreciation: Industry studies document typical silicone-based LED performance:

- L90 (90% lumen maintenance) at 30,000-40,000 hours for quality products

- L80 at 50,000-60,000 hours

- Accelerated depreciation in high-temperature or harsh-environment applications

- Some low-quality products reaching L70 before 20,000 hours

Color Shift: As silicone yellows and degrades:

- Color temperature shifts toward warmer (yellow) tones

- Color rendering index (CRI) declines

- Color point moves outside specified tolerance ranges

- Fixtures that started at 5000K may shift to 4200K or lower

Catastrophic Failures: Beyond gradual degradation, severe cases experience:

- Complete silicone discoloration (brown or opaque)

- Cracking and delamination exposing LED chips

- Wire bond corrosion causing open circuits

- Sudden complete failure requiring fixture replacement

For critical applications—sports venues, industrial facilities, roadway lighting—these failures create safety risks, operational disruptions, and expensive emergency maintenance.

Why the Industry Has Tolerated Silicone

Given these significant limitations, why has silicone dominated LED packaging for decades?

Processing Simplicity: Silicone can be dispensed as a liquid, mixed with phosphor, and cured at relatively low temperatures. This enables high-volume manufacturing with existing equipment.

Cost: Silicone materials are inexpensive and widely available from multiple suppliers.

Initial Performance: Fresh silicone packages perform well, meeting specifications at time of manufacture and initial testing.

Lack of Alternatives: Until recently, no viable alternative existed that could be manufactured at scale.

The industry has essentially accepted silicone’s limitations as inevitable compromises, attempting to mitigate them through:

- Sophisticated thermal management (expensive, adds weight)

- Protective coatings (limited effectiveness, add cost)

- Derating LEDs (sacrificing output per chip)

- Conservative lifetime ratings (under-promising performance)

But these are workarounds for a fundamental material limitation. What if the material itself could be replaced with something that simply doesn’t degrade?

Fluorescent Transparent Ceramic: A Fundamentally Different Approach

Ceramiclite has pioneered a radical departure from conventional LED packaging through its proprietary FTC technology, Fluorescent Transparent Ceramic. Rather than suspending phosphor particles in an organic polymer, FTC directly incorporates phosphor into a crystalline ceramic matrix, creating a solid-state phosphor conversion layer.

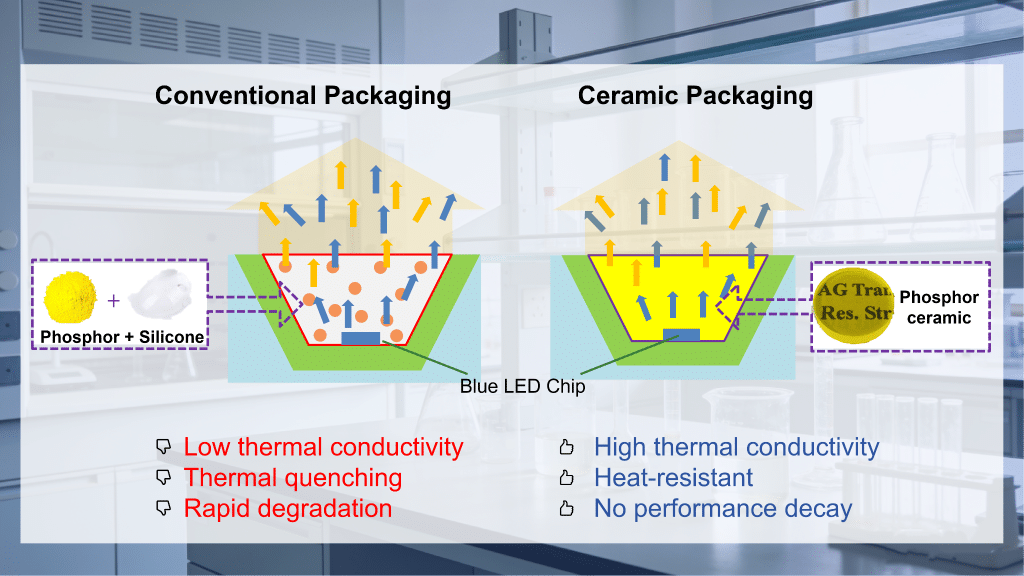

The FTC Architecture

FTC technology employs a fundamentally different structure:

- LED Chip: Blue-emitting semiconductor (unchanged from conventional designs)

- Fluorescent Transparent Ceramic Layer: A single-crystal or polycrystalline ceramic plate doped with phosphor ions throughout its crystalline structure

- Optical Coupling: Thin adhesive layer (orders of magnitude thinner than conventional silicone) bonding ceramic to chip

- Protective Coating: Minimal protective layer if needed for specific environments

The key innovation is the ceramic itself. Rather than phosphor particles floating in a polymer matrix, the phosphor is chemically integrated into the ceramic’s crystal lattice. The ceramic is simultaneously:

- The structural material (providing mechanical support and environmental protection)

- The optical medium (transparent to light)

- The phosphor host (containing the wavelength-conversion material)

This integration eliminates the organic polymer entirely, replacing it with an inorganic crystalline material that is fundamentally stable.

Material Properties: Why Ceramic Changes Everything

Absolute Thermal Stability: Inorganic ceramics are thermally stable to temperatures exceeding 1000°C. The operating temperatures in LED applications (80-120°C) are trivial by comparison:

- No polymer chain degradation (there are no polymer chains)

- No oxidative breakdown (ceramic is already fully oxidized)

- No phase changes or softening

- Crystal structure remains perfectly stable

- Optical properties unchanged by temperature

A ceramic phosphor layer operating at 100°C for 100,000 hours experiences zero thermal degradation. The material is as stable at the end as at the beginning.

Immunity to Photodegradation: Crystalline ceramics have wide electronic bandgaps typically 5-9 eV. Blue LED light at 2.75 eV per photon simply lacks the energy to break chemical bonds in the ceramic:

- No photo-oxidation

- No yellowing or discoloration

- No free radical formation

- Optical transparency maintained indefinitely

Even high-energy UV light (4-5 eV) remains below the threshold for ceramic degradation. The material is inherently immune to the photochemical damage that destroys silicone.

Moisture Impermeability: Dense ceramic is effectively impermeable to moisture:

- Water molecules cannot diffuse through the crystalline structure

- No moisture accumulation at LED chip interfaces

- Protection of metal contacts and wire bonds

- Elimination of moisture-accelerated degradation

This impermeability is particularly valuable for outdoor, agricultural, and marine applications where conventional silicone packages fail rapidly.

Matched Thermal Expansion: Advanced ceramics can be engineered with coefficients of thermal expansion closely matched to LED semiconductor materials:

- Ceramic CTE: 4-8 × 10⁻⁶ /°C (depending on composition)

- LED chip CTE: 3-7 × 10⁻⁶ /°C

- Excellent CTE matching (compared to silicone’s 300 × 10⁻⁶ /°C)

- Minimal thermal stress during cycling

- No cracking or delamination

- Maintained optical coupling over lifetime

Superior Thermal Conductivity: Many ceramic materials conduct heat far better than silicone:

- Silicone thermal conductivity: 0.15-0.25 W/m·K

- FTC ceramic: 15-35 W/m·K (100x better)

- Heat conducts away from LED junction more efficiently

- Lower operating temperatures

- Improved LED performance and lifespan

This thermal conductivity advantage creates a virtuous cycle: better heat removal enables higher drive currents without temperature penalties, allowing more light output per LED without compromising lifespan.

Mechanical Robustness: Ceramic provides superior mechanical properties:

- High hardness resists abrasion and scratching

- Excellent compressive strength

- Dimensional stability (no creep or deformation)

- Resistance to chemical attack

- UV stability for outdoor applications

The Performance Specifications: What FTC Delivers

The theoretical advantages of ceramic materials translate into extraordinary real-world performance specifications:

<5% Light Loss in 100,000 Hours: Independent testing of FTC-based LED modules demonstrates:

- L95 (95% lumen maintenance) at 100,000+ hours

- Essentially zero degradation visible in accelerated aging tests

- Maintained performance regardless of operating temperature (within LED safe limits)

- No measurable color shift over lifetime

Compare this to conventional silicone packages:

- Typical L90 at 30,000-40,000 hours

- L80 at 50,000-60,000 hours

- FTC outlasts silicone by 2-3x at equivalent maintenance levels

50x Lower Thermal Resistance: The junction-to-case thermal resistance in FTC LED packages measures dramatically lower than silicone equivalents:

- Conventional silicone package: 8-15 °C/W (chip to case)

- FTC package: 0.2-0.5 °C/W (chip to case)

- Reduction factor: 15-75x (50x typical)

Lower thermal resistance means:

- LED junction temperatures 20-40°C cooler at equivalent drive currents

- Ability to drive LEDs harder without thermal penalties

- Improved light output per chip

- Extended LED semiconductor lifespan

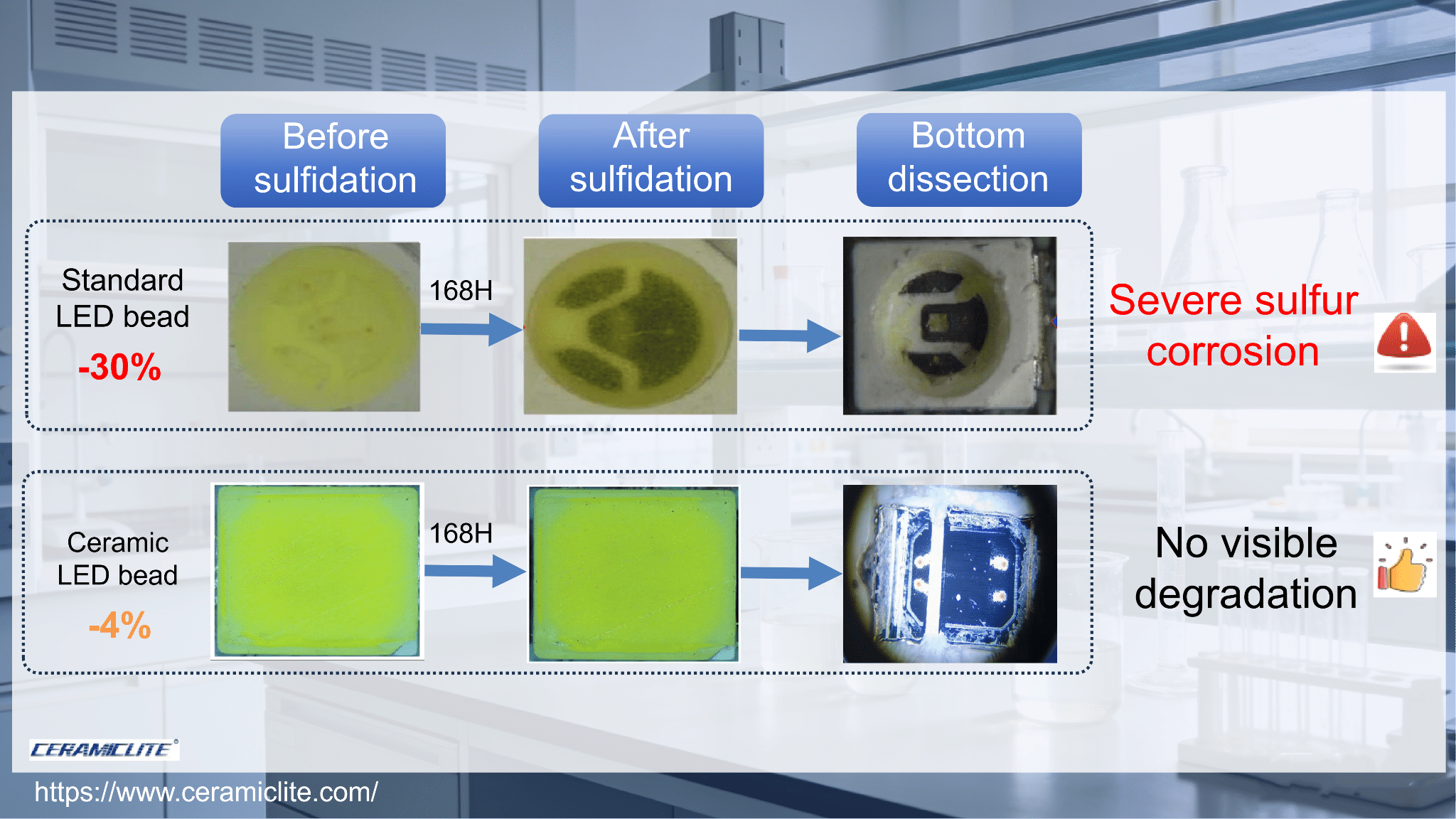

Absolute Corrosion Immunity: Inorganic ceramics simply don’t corrode in environments that destroy organic materials:

- Ammonia (agricultural facilities): No effect on ceramic

- Salt spray (marine/coastal): No corrosion

- Industrial chemicals: Chemically inert

- UV radiation: No degradation

- Humidity: Impermeable, no water intrusion

Field testing in ammonia-rich poultry barns demonstrates:

- Conventional LED packages: visible degradation in 12-18 months, failure in 24-36 months

- FTC LED packages: zero visible degradation after 8+ years of continuous operation

Manufacturing Challenges and Solutions

The obvious question: if ceramic is so superior, why isn’t everyone using it?

Technical Complexity: Manufacturing fluorescent transparent ceramics requires sophisticated processes:

- High-purity raw materials (99.99%+ purity)

- Precise phosphor doping control

- High-temperature sintering (1400-1800°C)

- Crystal structure control for optical transparency

- Precision machining and polishing for optical surfaces

These processes demand specialized equipment and expertise beyond typical LED manufacturing capabilities.

Historical Cost: Early ceramic phosphor materials were prohibitively expensive—10-20x the cost of silicone packages. Only niche applications could justify the premium.

Scale-Up Challenges: Transitioning from laboratory samples to high-volume production requires:

- Consistent quality control across large production runs

- Yield optimization to reduce manufacturing defects

- Supply chain development for specialized materials

- Process refinement to reduce cycle times

Ceramiclite has invested heavily in overcoming these challenges, developing proprietary manufacturing processes that enable commercially viable production:

Advanced Sintering Techniques: Optimized sintering profiles create fully dense, optically transparent ceramics with controlled crystal structures.

Doping Precision: Automated phosphor introduction systems ensure uniform concentration and distribution throughout ceramic bodies.

Quality Control: In-line optical testing verifies transparency, fluorescence efficiency, and consistency before final assembly.

Cost Reduction: Economies of scale and process optimization have reduced FTC costs to levels viable for premium commercial applications, with continued cost reduction as volumes increase.

Real-World Validation: FTC in Demanding Applications

Theoretical superiority means nothing if it doesn’t translate to field performance. Ceramiclite’s FTC-based LED products have accumulated substantial real-world operating data across challenging applications.

Agricultural Lighting: The Ultimate Stress Test

Agricultural facilities—particularly poultry and dairy barns—present perhaps the most hostile environment for LED lighting:

- Ammonia concentrations: 15-50 ppm continuous exposure

- Humidity: 60-90% relative humidity

- Temperature cycling: -10°C to +40°C seasonally

- Dust and particulates: Heavy contamination

- 24/7 operation: Continuous photoperiod programs

Conventional LED Performance:

- Visible silicone yellowing: 12-18 months

- Significant light output loss: 18-24 months

- Fixture replacement required: 24-36 months

- Effective lifespan: 20,000-30,000 hours maximum

FTC LED Performance:

- Zero visible degradation: 8+ years continuous operation

- Light output maintenance: >95% after 70,000+ hours

- No failures requiring replacement

- Projected lifespan: 100,000+ hours (15-20+ years at typical agricultural use)

A dairy farm in the Netherlands operating FTC-based LED fixtures since 2016 reports: “We replaced failed conventional LED lights twice in the first five years. The FTC fixtures installed at the same time show zero degradation. The difference is night and day—literally. These lights simply don’t fail.”

Sports Lighting: High-Power, High-Stakes Applications

Professional sports lighting demands:

- Extremely high drive currents (high power per LED)

- Elevated junction temperatures

- Absolutely consistent color rendering for broadcasting

- Zero tolerance for failures during events

- Long-term photometric stability

Performance Data from Professional Stadium Installation:

- 600 × 1,000W FTC-based LED fixtures

- 5+ years operation (2019-2024)

- 2,000+ hours annual operation

- Photometric testing results:

- Initial average illuminance: 1,850 lux

- Year 5 average illuminance: 1,823 lux (98.5% maintained)

- Color temperature shift: <100K (within measurement error)

- Zero fixture failures

The facility manager notes: “Our previous LED system required replacing 15-20 fixtures annually due to failures and degradation. In five years with FTC technology, we’ve replaced zero fixtures. The consistency matters enormously for broadcast color rendering doesn’t shift, uniformity remains perfect, and we never worry about a dark zone appearing during a match.”

Coastal and Marine Applications

Salt-laden air destroys conventional LED fixtures:

- Aluminum corrodes rapidly

- Silicone degrades from salt contamination

- Moisture intrusion accelerates all failure modes

A coastal parking facility in Portugal replaced conventional LED area lights (average 3-year lifespan) with FTC-based fixtures in 2017:

- 7+ years continuous operation

- Zero corrosion-related failures

- Maintained light output and color quality

- Dramatic reduction in maintenance costs

“We used to budget for complete parking lot lighting replacement every 3-4 years,” the facilities director explains. “We’re now in year 7 with the FTC fixtures and haven’t replaced a single light. The total cost savings eliminating three replacement cycles—paid for the higher initial cost twice over.”

Industrial High-Bay Facilities

Manufacturing facilities with 24/7 operations, elevated temperatures, and chemical exposures demonstrate FTC advantages:

A chemical processing plant in Germany:

- 350 × 200W FTC high-bay fixtures

- Installed 2018

- 8,500+ hours annual operation (effectively 24/7)

- 6+ years, 51,000+ operating hours

- Photometric testing: 97% lumen maintenance

- Zero failures

“Our previous LED fixtures required replacement at 30,000-35,000 hours due to degradation,” the plant engineer notes. “We’re now past 50,000 hours with FTC technology and showing minimal decline. This directly impacts production, no disruptions for lighting maintenance, no dark spots developing that create safety concerns, consistent visibility for quality control.”

The Economic Case: Total Cost of Ownership

FTC technology commands a price premium over conventional LED packages typically 40-60% higher initial cost at fixture level. Yet total cost of ownership calculations consistently favor FTC for demanding applications.

Lifecycle Cost Analysis: Industrial Facility Example

Scenario: 500-fixture industrial facility, 24/7 operation (8,500 hours/year)

Option 1: Conventional Silicone-Based LED

- Fixture cost: £200 each

- Initial investment: £100,000

- Expected lifespan: 35,000 hours (4.1 years)

- Replacement cycles in 20 years: 4 additional purchases

- Total fixture cost (20 years): £500,000

- Installation labor per cycle: £15,000

- Total labor: £75,000

- 20-year total: £575,000

Option 2: FTC-Based LED

- Fixture cost: £300 each (50% premium)

- Initial investment: £150,000

- Expected lifespan: 100,000+ hours (11.8+ years)

- Replacement cycles in 20 years: 1 additional purchase

- Total fixture cost: £300,000

- Installation labor: £15,000 (one cycle only)

- 20-year total: £315,000

- Net savings: £260,000 (45% lower total cost)

The initial premium is more than offset by eliminating three replacement cycles and associated installation costs.

Additional Economic Benefits

Avoided Production Disruptions: Manufacturing facilities report that lighting maintenance causes production interruptions:

- Line shutdowns during fixture replacement

- Reduced productivity in degraded lighting conditions

- Safety incidents in poorly lit areas

Eliminating multiple replacement cycles avoids these disruptions. For high-value manufacturing, even brief production pauses can cost thousands of pounds per hour.

Energy Efficiency Gains: FTC’s superior thermal management allows:

- Higher luminous efficacy (more light per watt)

- 8-12% energy savings compared to equivalent silicone-based fixtures

- Maintained efficiency over lifetime (no degradation-driven efficiency loss)

For a large facility, 10% energy savings can amount to £20,000-£40,000 annually.

Reduced Spare Parts Inventory: Facilities typically maintain spare fixture inventory for emergency replacements. FTC’s reliability allows:

- Smaller spare parts inventory

- Reduced capital tied up in spares

- Less warehouse space dedicated to lighting components

Sustainability Value: Eliminating frequent replacements delivers environmental benefits that matter increasingly to corporate sustainability programs:

- 75% reduction in electronic waste

- Lower cumulative manufacturing carbon footprint

- Reduced transportation emissions

- Alignment with circular economy principles

Some organizations can quantify this through internal carbon pricing or sustainability reporting requirements, adding further economic value to FTC’s longevity.

Technical Deep Dive: The Science Behind FTC

For those interested in the materials science enabling FTC technology, the underlying principles reveal why this approach succeeds where silicone fails.

Crystal Structure and Optical Properties

FTC ceramics typically employ yttrium aluminum garnet (Y₃Al₅O₁₂, or YAG) as the host crystal, doped with cerium ions (Ce³⁺) as the luminescent center—the same phosphor composition used in conventional LEDs, but incorporated differently.

In Conventional LEDs: YAG:Ce exists as fine powder particles (2-20 μm diameter) suspended in silicone. Light scattering at particle boundaries reduces optical efficiency.

In FTC: Ce³⁺ ions are incorporated into the YAG crystal lattice during crystal growth. The result is a single-phase transparent ceramic with uniform phosphor distribution and no scattering boundaries.

Transparency Mechanism: Pure YAG is naturally transparent—it’s used in high-power laser optics. The challenge is maintaining transparency while adding phosphor dopants and manufacturing at scale. Ceramiclite’s proprietary processes achieve:

- 85% optical transmission through 0.5-1mm ceramic plates

- Minimal light scattering from residual porosity or grain boundaries

- Uniform absorption and emission across entire ceramic volume

Thermal Management at the Microscale

FTC’s thermal advantages operate at multiple scales:

Material Level: YAG ceramic thermal conductivity (15-35 W/m·K) exceeds silicone (0.15-0.25 W/m·K) by 100x. Heat conducts rapidly from LED junction through ceramic.

Interface Level: The thin adhesive layer bonding ceramic to LED chip (typically <10 μm) introduces minimal thermal resistance compared to the thick silicone layers (200-500 μm) in conventional packages.

System Level: Because FTC removes heat more effectively, LED junction temperatures are lower. This creates cascading benefits:

- Lower temperature → higher LED efficiency → less heat generation

- Positive feedback reducing thermal stress throughout system

Practical Result: Thermal imaging of identical LED chips operating at equivalent drive currents shows:

- Conventional silicone package: junction temperature ~115°C

- FTC package: junction temperature ~75°C

- 40°C temperature reduction dramatically extending LED semiconductor lifespan

Degradation Kinetics: Why Ceramic Doesn’t Age

The stability of FTC can be understood through chemical kinetics. Degradation reactions follow Arrhenius relationships reaction rates double for every 10°C temperature increase (approximate rule).

For silicone degradation at LED operating temperatures:

- Activation energy: ~80-100 kJ/mol

- At 100°C: Measurable degradation within thousands of hours

- At 120°C: Degradation rates 4-8x faster

For ceramic degradation:

- Activation energy: >400 kJ/mol (breaking ionic bonds in crystal lattice)

- At 100°C: No measurable degradation even over geological timescales

- LED operating temperatures are orders of magnitude too low to affect ceramic

This isn’t a matter of ceramic degrading more slowly it’s that LED operating conditions simply cannot cause ceramic degradation at any measurable rate.

Industry Implications: The Technology Transition

FTC’s proven advantages are beginning to reshape the LED industry, though adoption faces the inertia characteristic of established technologies.

Market Segmentation

FTC technology is gaining fastest adoption in segments where reliability and performance justify premium pricing:

Premium Commercial and Industrial: Facilities with high labor costs for maintenance, 24/7 operations, or stringent reliability requirements increasingly specify FTC.

Harsh Environments: Agricultural, marine, and chemical facilities where conventional LEDs fail rapidly find FTC economics compelling despite higher initial costs.

High-Performance Applications: Sports lighting, broadcast facilities, and professional venues where consistent performance is critical.

Long-Term Infrastructure: Municipal street lighting, tunnel lighting, and other applications where replacement is expensive and disruptive.

Barriers to Broader Adoption

Several factors slow FTC market penetration:

Initial Cost Perception: Despite favorable lifecycle economics, higher upfront costs create procurement barriers, particularly for organizations with limited capital budgets or short planning horizons.

Industry Conservatism: Lighting specifications often default to familiar technologies. Changing specifications requires education and sometimes lengthy approval processes.

Supply Chain Development: FTC manufacturing requires specialized capabilities not widely available. Limited suppliers constrain availability.

Performance Familiarity: The industry has decades of experience managing silicone limitations through thermal management, derating, and conservative specifications. FTC’s dramatically different failure modes (essentially none) challenge established design practices.

The Path Forward

As FTC manufacturing scales and costs decline, adoption will accelerate:

Cost Trajectory: Ceramiclite projects 20-30% cost reductions over next 3-5 years as:

- Manufacturing processes mature and yields improve

- Raw material costs decrease through volume purchasing

- Competition enters the market driving efficiency

Specification Evolution: Leading standards organizations are beginning to recognize advanced packaging technologies:

- LM-80 testing protocols being adapted for long-life technologies

- Specifications for critical applications starting to require demonstrated long-term stability

- Total cost of ownership calculations being incorporated into procurement decisions

Market Education: As early adopters document performance and cost savings, broader market awareness increases. Case studies and field data overcome initial skepticism.

Adjacent Technology Developments: Beyond lighting, FTC-type technologies are being explored for:

- Display applications (micro-LED screens)

- Automotive lighting (extreme reliability requirements)

- Aerospace and defense (harsh environment tolerance)

- Medical devices (biocompatibility and stability)

Success in these adjacent markets will drive further cost reduction and manufacturing scale benefiting lighting applications.

Conclusion: The Materials Matter

The transition from silicone to fluorescent transparent ceramic in LED packaging represents more than incremental improvement; it’s a fundamental solution to degradation mechanisms that have limited LED performance since the technology’s inception.

Silicone degrades because organic polymers fundamentally cannot withstand the temperature, light energy, and environmental exposure inherent in LED operation. Decades of engineering optimization have minimized but not eliminated these limitations. The solution isn’t better silicone, it’s replacing silicone with a material that simply doesn’t share its vulnerabilities.

Ceramiclite’s FTC technology demonstrates that advanced materials science can deliver order-of-magnitude improvements in real-world performance: <5% light loss over 100,000 hours, 50x lower thermal resistance, and immunity to corrosion that destroys conventional packages.

For applications where reliability, longevity, and maintained performance matter industrial facilities, sports venues, agricultural operations, outdoor infrastructure the economic case for FTC is compelling despite initial cost premiums. Eliminating multiple replacement cycles over a 20-year period typically delivers 40-60% total cost savings while avoiding production disruptions and maintenance labor.

More broadly, FTC exemplifies how materials science breakthroughs enable technology transitions. LED efficiency improvements have slowed as semiconductor physics approaches theoretical limits. Further performance gains increasingly depend on improvements in supporting technologies thermal management, optics, and packaging. Advanced ceramics removing degradation bottlenecks unlock LED potential that semiconductor improvements alone cannot access.

The LED industry is gradually recognizing what materials science has demonstrated: the future of long-life, high-reliability LED technology is solid-state ceramic phosphors integrated into crystalline structures, not organic polymers with inherent degradation pathways.

Silicone served the industry adequately when LEDs were low-power devices in controlled environments. As applications have become more demanding, higher powers, harsher conditions, longer required lifespans, silicone’s limitations have become unacceptable. FTC technology points toward a future where LED fixtures routinely operate for decades without degradation, where promised lifespans are conservative rather than optimistic, and where the environmental benefits of LED efficiency are multiplied by extreme longevity.

The materials revolution enabling this future is already underway. The question isn’t whether ceramic will replace silicone in demanding applications field data has already answered that. The question is how quickly manufacturing will scale, costs will decline, and the broader market will recognize that the material surrounding the LED chip matters just as much as the chip itself.

For Ceramiclite and the growing number of organizations adopting FTC technology, the answer is clear: beyond silicone lies a future of LED reliability that finally matches the technology’s promise.