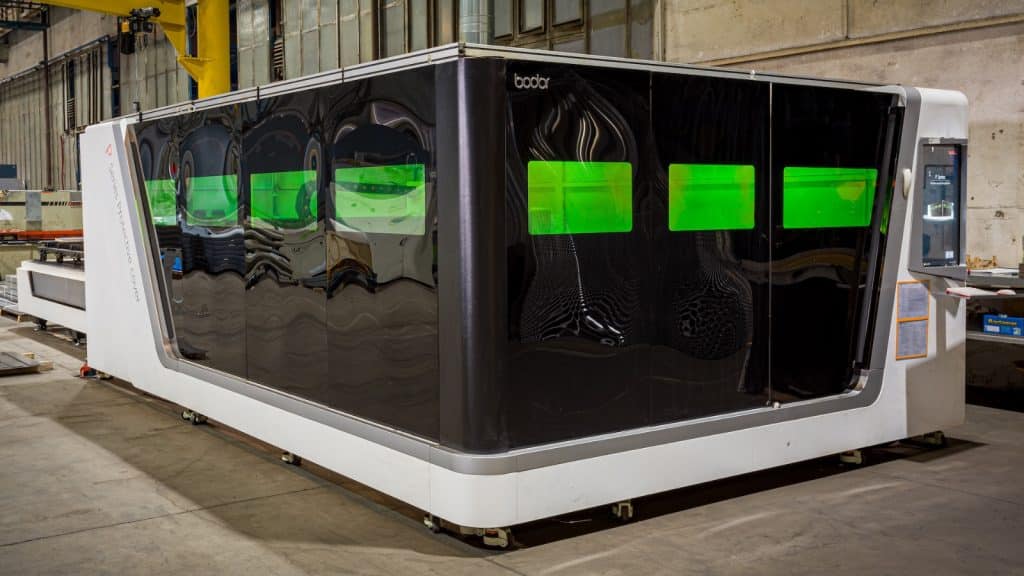

In the spring of 2025, a major industrial injury lawsuit involving a laser cutting machine placed Chinese manufacturer Bodor Laser under legal scrutiny in the United States. The case has triggered renewed concern across North America’s metal fabrication sector regarding equipment safety responsibility. The plaintiffs allege that the Bodor machine lacked basic protective mechanisms, leading to a fatal workplace incident.

The case has been officially filed in Nevada state court and is scheduled for jury trial in the fall of 2026.

Product Liability in Focus: Cost Advantage Shouldn’t Override Safety

According to the publicly available court documents, the equipment in question lacked any form of interlock system, collision detection mechanism, or protective shielding for the laser path. The plaintiffs claim that the manufacturer and its partners failed in their duty to provide a reasonably safe product, amounting to both design defects and insufficient warnings.

Court filings reveal that the operator was fatally injured when the Bodor machine unexpectedly activated and emitted high-powered laser energy. The equipment, according to the complaint, lacked “any safety interlock or collision detection systems” and was structurally incapable of protecting the operator from direct exposure.

Furthermore, the plaintiffs argue that Bodor failed to adequately communicate the injury risks through its product documentation, promotional materials, or training, amounting to “gross negligence in safety disclosure.”

This case echoes several high-profile industrial safety lawsuits in recent history:

- In 2014, a robotic automation manufacturer was ordered to pay over $12 million in damages following a workplace crushing incident, largely due to the lack of an emergency interlock.

- In 2019, a welding equipment company paid $8.5 million in a misfire injury case, stemming from insufficient trigger safeguards.

Such precedents highlight that in the U.S. market, liability extends beyond operational misuse and includes preventive design obligations.

Defendants: China-U.S. Corporate Network Named

Multiple entities have been named as co-defendants in the lawsuit, including:

- Bodorlaser Inc. (U.S. subsidiary)

- Jinan Bodor CNC Machine Co., Ltd. (China headquarters)

- XOVR Inc. and related service/parts firms

The suit alleges these parties jointly participated in the sale, delivery, and maintenance of the machine and should be held jointly liable for the safety failures.

Legal Trend: Safety Accountability Goes Global

As industrial equipment manufacturers expand globally, U.S. courts have increasingly applied local safety statutes to foreign-made equipment, particularly when local service partners are involved.

Legal experts point out that even if a machine is designed to non-U.S. standards, once it enters the U.S. market and is supported by domestic partners, it must comply with OSHA requirements and ANSI standards like Z136.1.

Industry Reaction: Power Growth, Safety Gap

As high-power laser systems (12kW and up) become more accessible to midsize manufacturers in North America, safety by design is gaining urgency. Some newer market entrants have emphasized affordability through open-frame structures and optional safety kits, pushing the burden of risk management to end users.

A system integrator on the U.S. West Coast noted: “We see more mid-sized shops placing laser machines directly on open floors, no enclosures, and no secondary safety confirmation. Without built-in safeguards, it’s a matter of time before something goes seriously wrong.”

Conclusion: Compliance Is the Baseline

The outcome of this case remains to be seen, but its implications are already resonating: performance must not come at the expense of safety. As smart manufacturing accelerates, baseline safety design is becoming a deciding factor in equipment selection.