Definition of CNC Machining

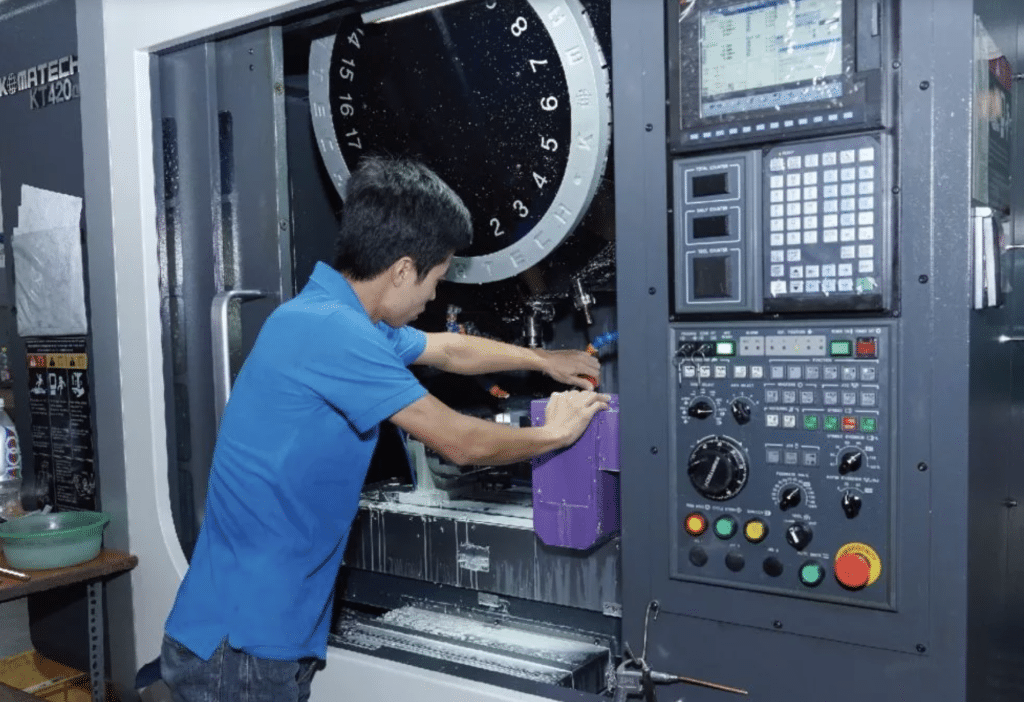

CNC (Computer Numerical Control) machining is a cutting-edge manufacturing process that harnesses the power of pre-programmed computer software to precisely control the intricate movements of machinery and tools in factories. This highly sophisticated and automated method is widely embraced to shape and cut an array of materials, ranging from metals and plastics to wood and composites. The end result is the creation of a diverse range of exceptional products, showcasing the remarkable capabilities of this technology.

Importance of CNC Machining Services

Precision and Accuracy: CNC machining offers unparalleled precision, allowing for the production of complex and intricate components with tight tolerances.

Efficiency: Automation in CNC machining streamlines production processes, reducing human error and increasing efficiency.

Versatility: CNC machines can handle a variety of materials, making them suitable for diverse industries, including aerospace, automotive, healthcare, and electronics.

Global Significance of CNC Machining Industry

The CNC machining industry plays a pivotal role in the global manufacturing landscape, influencing the development of various sectors. Its impact is felt across economies, contributing to technological advancements, job creation, and the overall growth of industries worldwide.

Overview of CNC Machining Services in China

Growth and Expansion

Historical Development: China has witnessed significant growth in its CNC machining sector over the past few decades, fueled by industrialization and technological advancements.

Current Market Trends: The Chinese CNC machining market is characterized by innovation, increased automation, and a focus on high-volume production.

Technological Advancements

Adoption of Advanced CNC Technologies: Chinese manufacturers are embracing cutting-edge CNC technologies, including multi-axis machining and additive manufacturing.

Integration of Automation and Robotics: Automation is increasingly integrated into CNC machining processes, enhancing production speed and efficiency.

Industry Regulations

Regulatory Environment in China: Overview of key regulations governing CNC machining services in China and their impact on the industry.

Impact on CNC Machining Services: Discussion of how regulations influence business practices, quality standards, and market dynamics in China’s CNC machining sector.

Overview of CNC Machining Services in the USA

Historical Perspective

Evolution of CNC Machining in the USA: A historical overview of the development and evolution of CNC machining in the United States.

Key Milestones: Highlighting significant milestones, breakthroughs, and innovations that have shaped the CNC machining industry in the USA.

Current Landscape

Market Size and Growth: Examination of the current size and growth trends in the U.S. CNC machining market, considering factors such as demand, investments, and technological advancements.

Innovation and Research in CNC Machining: Overview of ongoing research, innovation, and development initiatives within the U.S. CNC machining sector.

Regulatory Framework

Compliance and Standards in the USA: Discussion of regulatory compliance requirements and quality standards applicable to CNC machining services in the United States.

Influence on CNC Machining Practices: Analysis of how regulatory frameworks impact business operations, quality assurance, and market competitiveness in the U.S. CNC machining industry.

CNC Machining service Comparative Analysis

Cost Factors

Labor Costs:

China:

China is known for its relatively lower labor costs compared to many Western countries.

Availability of a large skilled labor force contributes to cost competitiveness.

USA:

Higher labor costs due to labor regulations, standards, and a higher cost of living.

Focus on skilled labor and advanced expertise may influence wage structures.

Material Costs:

China:

Access to affordable raw materials due to proximity to manufacturing hubs.

Potential variations in material quality based on supplier networks.

USA:

Higher material costs influenced by quality standards and transportation expenses.

Emphasis on reliable and standardized material sources.

Operational Costs:

China:

Lower operational costs attributed to a favorable business environment.

Varied costs influenced by regional economic disparities.

USA:

Higher operational costs due to regulatory compliance, energy expenses, and infrastructure investments.

Focus on efficiency and sustainable practices may impact costs.

Quality and Precision

Standards and Certifications:

China:

Growing emphasis on meeting international quality standards.

Certification processes evolving to align with global expectations.

USA:

Adherence to stringent quality standards and certifications.

Established reputation for high-quality manufacturing practices.

Precision Levels in CNC Machining:

China:

Advancements in technology contribute to improved precision.

Variability in precision levels among different manufacturers.

USA:

Long-standing expertise and focus on precision engineering.

Consistent reputation for high precision and accuracy in CNC machining.

Lead Times and Turnaround

Manufacturing Speed and Efficiency:

China:

High-speed manufacturing capabilities, especially for large-scale production.

Rapid response to market demands with efficient production processes.

USA:

Emphasis on lean manufacturing principles and streamlined processes.

Quick adaptation to changing market requirements.

Logistics and Shipping Considerations:

China:

Strategic geographical location facilitates efficient global shipping.

Potential delays due to global supply chain challenges.

USA:

Robust logistics infrastructure ensuring timely deliveries.

Regional production capabilities influencing shipping efficiency.

Challenges and Opportunities

Common Challenges in CNC Machining Services

Global Supply Chain Disruptions:

Exploration of challenges posed by disruptions in the global supply chain affecting both China and the USA.

Strategies to mitigate risks and enhance resilience.

Technological Obsolescence:

Analysis of challenges related to the rapid evolution of CNC machining technologies.

Importance of ongoing training and investment in cutting-edge technologies.

B. Emerging Opportunities in the Global Market

Customization and Personalization:

Examination of opportunities arising from the growing demand for customized CNC machined products.

Strategies for adapting to the trend and meeting consumer expectations.

Sustainable Practices:

Exploration of opportunities presented by the emphasis on sustainability in manufacturing.

Integration of eco-friendly practices and materials in CNC machining services.

C. Strategies for Overcoming Challenges

Collaborative Partnerships:

Discussion on the benefits of collaborative partnerships within the CNC machining ecosystem.

Examples of successful collaborations in overcoming industry challenges.

Investment in Technology and Training:

Importance of continuous investment in advanced technologies and employee training.

Case studies highlighting successful implementation of technology-driven strategies.

Final Thoughts on the Future of CNC Machining Services

Recap of Key Findings

In this comparative analysis of CNC machining services in China and the USA, several key findings have emerged. From cost factors and quality considerations to lead times and successful case studies, both countries showcase distinct strengths and challenges in the CNC machining industry.

Implications for Businesses and Decision-Makers

Global Collaboration:

The importance of global collaboration and strategic partnerships to leverage the strengths of both Chinese and U.S. CNC machining services.

Opportunities for cross-border collaborations to enhance efficiency and innovation.

Adaptability to Market Dynamics:

The significance of adaptability in response to market dynamics, considering factors such as changing consumer preferences and global supply chain disruptions.

Businesses need to be agile in navigating challenges and seizing emerging opportunities.

As we look to the future of CNC machining services, the industry is poised for continued innovation and growth. The integration of advanced technologies, sustainable practices, and a focus on precision will shape the landscape of CNC machining in both China and the USA.