In high-performance industries such as aerospace, medical devices, automotive, and defense, selecting the right material is crucial to meeting specific application needs. Two materials that often stand out due to their unique properties are tungsten and titanium. Both materials offer advantages, but their distinct differences make them better suited for certain projects.

This article will provide an in-depth comparison of tungsten vs titanium, focusing on their material properties, common applications, and the technical challenges associated with machining them using CNC technology. By understanding how each material performs in different conditions, businesses can make more informed decisions when choosing between tungsten and titanium for their custom CNC machined parts.

Tungsten vs Titanium: A Comparison of Material Properties

When comparing tungsten and titanium, several key material properties highlight their respective strengths and weaknesses. Below, we expand on the core properties to provide more insights into how they behave under different conditions and why these properties matter for CNC machining.

1. Density and Weight

| Material | Density | Weight | Application Impact |

| Tungsten | 19.25 g/cm³ | Extremely dense and heavy | Ideal for applications where high mass is needed, such as counterweights, projectiles, and radiation shielding. |

| Titanium | 4.5 g/cm³ | Lightweight compared to tungsten | Perfect for industries like aerospace and automotive, where reducing weight is crucial for performance and efficiency. |

Tungsten is one of the densest metals, about 4 times denser than titanium. This extreme density makes it suitable for applications that require weight and inertia, such as armor-piercing projectiles or radiation shielding. However, its weight can be a limitation for applications that prioritize lightness and mobility.

Titanium, in contrast, is known for its exceptional strength-to-weight ratio. With only a fraction of tungsten’s density, it is widely used in lightweight yet durable structures such as aircraft frames, automotive parts, and medical implants. Its lightweight nature makes it ideal for applications where reducing weight improves performance without sacrificing strength.

2. Hardness and Strength

| Material | Mohs Hardness | Yield Strength | Application Impact |

| Tungsten | 7.5 | 750 MPa | Harder and more brittle than titanium; useful for high-wear applications like cutting tools or drill bits. |

| Titanium | 6 | 480 MPa | High strength and more ductile, making it better suited for load-bearing components. |

Tungsten’s high hardness makes it extremely resistant to wear, which is why it’s commonly used for cutting tools, mining equipment, and high-wear parts. However, its brittleness means it is more prone to cracking under extreme mechanical stress, making it less ideal for components that require flexibility or ductility.

Titanium, while not as hard as tungsten, offers impressive yield strength and ductility, which allows it to withstand significant stress without fracturing. This makes it particularly useful in load-bearing applications like aircraft landing gear or prosthetic limbs where both strength and flexibility are essential.

3. Melting Point and Heat Resistance

| Material | Melting Point | Thermal Stability | Application Impact |

| Tungsten | 3,422°C | Extremely high, excellent for high-temperature applications. | Ideal for use in rocket nozzles, furnace parts, and applications requiring heat shields. |

| Titanium | 1,668°C | High but lower than tungsten | Commonly used in turbine engines, exhaust systems, and heat-exposed parts. |

Tungsten’s incredibly high melting point makes it one of the best materials for high-temperature environments. It can endure temperatures above 3,000°C, making it essential for use in aerospace and defense industries where parts are exposed to extreme heat, such as rocket nozzles and furnace components.

Although titanium’s melting point is significantly lower, it still offers superior thermal stability compared to many other metals. It’s frequently used in jet engines, automotive exhaust systems, and heat exchangers where heat resistance is crucial, but the weight of the part also matters.

4. Corrosion Resistance

| Material | Corrosion Resistance | Suitability for Harsh Environments | Application Impact |

| Tungsten | Low | Poor resistance, tends to corrode over time unless alloyed or treated | Not ideal for environments exposed to moisture or chemicals. Often needs protective coatings. |

| Titanium | Excellent | Naturally corrosion-resistant, ideal for marine, medical, and chemical environments | Ideal for implants, marine parts, and chemical processing equipment. |

One of titanium’s most notable advantages over tungsten is its natural corrosion resistance. Titanium can withstand exposure to saltwater, acids, and other harsh chemicals without corroding, making it perfect for marine applications, medical implants, and chemical processing equipment. Tungsten, on the other hand, is more susceptible to oxidation and corrosion, particularly when exposed to moisture or corrosive environments. While tungsten alloys can mitigate some of these issues, they typically require additional protective treatments.

Common Applications of Tungsten and Titanium

Understanding the typical applications of each material will help you see where CNC technology can deliver high-precision parts based on your requirements.

Tungsten Applications:

- Aerospace Components: Tungsten’s high melting point makes it suitable for high-temperature environments, such as rocket nozzles and heat shields.

- Defense and Military: Tungsten is used in armor-piercing projectiles, where high density and durability are key factors.

- High-Wear Industrial Parts: Tungsten’s hardness is ideal for cutting tools, mining equipment, and electrical contacts in high-wear applications.

- Radiation Shielding: Tungsten alloys are often used in medical imaging and radiation therapy devices for shielding.

Titanium Applications:

- Aerospace Parts: Lightweight yet durable, titanium is perfect for aircraft components such as landing gear, turbine blades, and airframe parts.

- Medical Devices: Titanium’s biocompatibility and corrosion resistance make it the material of choice for dental implants, bone screws, and prosthetics.

- Automotive Components: High-performance cars use titanium for exhaust systems, engine parts, and suspension systems where weight reduction is crucial.

- Marine Applications: Due to its exceptional corrosion resistance, titanium is ideal for parts exposed to seawater, such as boat propellers and underwater drilling components.

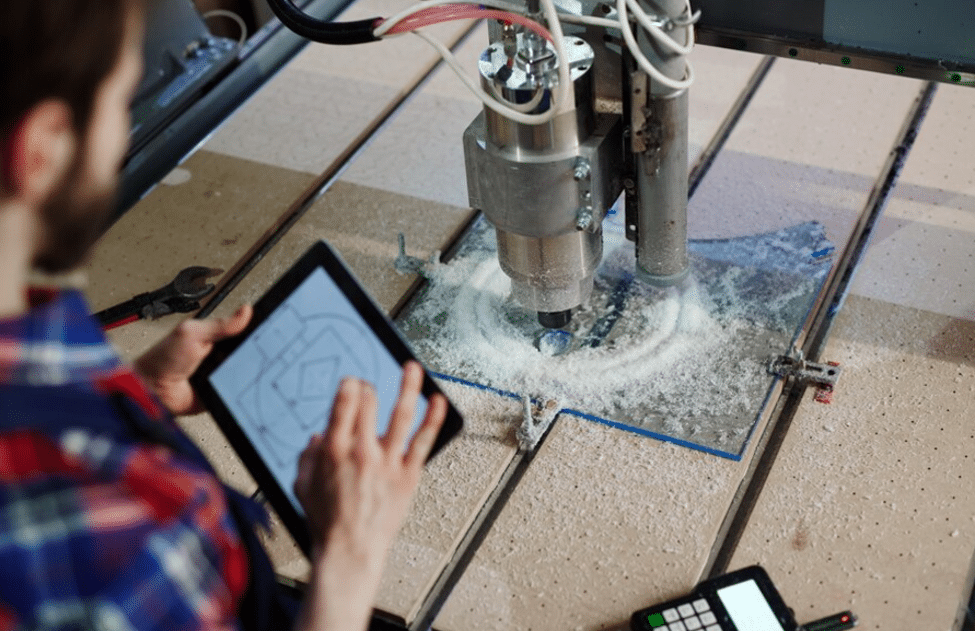

Technical Challenges of CNC Machining Tungsten and Titanium

While both tungsten and titanium are valuable materials, they present unique machining challenges. CNC technology allows for precise machining, but understanding these materials’ specific requirements is crucial.

Machining Tungsten:

- Tool Wear: Tungsten’s high hardness leads to faster tool wear, requiring special cutting tools, often made from carbide or diamond.

- Brittleness: Tungsten can be brittle and prone to cracking, making it challenging to machine without precise control over cutting speeds and feeds.

- Heat Management: Since tungsten retains heat during machining, cooling systems are essential to prevent overheating.

Machining Titanium:

- Galling and Work Hardening: Titanium can gall (adhesion between the tool and the material), which increases tool wear and makes machining more difficult.

- Heat Sensitivity: Titanium retains heat and can warp under intense machining, so high coolant flow is necessary to keep the part cool.

- Cutting Forces: CNC machines must operate with lower cutting forces to avoid damaging the part, requiring more time and precision.

| Material | Machining Difficulty | Tool Wear | Heat Management Needed | Cutting Speed |

| Tungsten | Very high | High | Essential | Low to medium |

| Titanium | Medium | Moderate | Critical | Low |

CNC Machining Solutions for Tungsten and Titanium

CNC technology offers several solutions to overcome these machining challenges:

- High Precision Control: CNC machines can fine-tune cutting speeds and feeds to accommodate the hardness or sensitivity of the material.

- Advanced Cooling Systems: CNC machines use specialized cooling fluids to manage the heat generated during titanium machining.

- Custom Tooling: For machining tungsten, CNC machines can be equipped with high-performance cutting tools made from polycrystalline diamond (PCD) or carbide.

Choosing Between Tungsten and Titanium Based on Application Needs

Choosing between tungsten and titanium depends on several factors, including the specific application, performance requirements, and operating environment. Below is an expanded guide to help determine the best material for your custom CNC parts based on different industry needs.

1. Aerospace Applications

| Material | Ideal Use | Considerations |

| Tungsten | Heat shields, rocket nozzles, aerospace counterweights | Suitable for high-heat, high-wear components, but not ideal for weight-sensitive parts. |

| Titanium | Aircraft frames, turbine blades, landing gear | Perfect for weight-sensitive and high-stress applications due to its high strength-to-weight ratio. |

In the aerospace industry, weight reduction is crucial for improving fuel efficiency and overall performance. Titanium is preferred for components that must be both lightweight and strong, such as turbine blades and aircraft frames. Meanwhile, tungsten is used in parts that require extreme heat resistance, such as heat shields or rocket components.

2. Medical Devices and Implants

| Material | Ideal Use | Considerations |

| Tungsten | Radiation shielding, medical tools requiring high wear resistance | Not suitable for implants due to corrosion issues. Can be used in protective equipment. |

| Titanium | Implants (e.g., hip replacements, bone screws), dental implants | Biocompatible and corrosion-resistant, making it perfect for long-term use inside the body. |

For medical devices, biocompatibility and corrosion resistance are critical. Titanium is the go-to material for implants, including hip replacements, bone screws, and dental implants, due to its ability to integrate with human tissues without causing adverse reactions. Tungsten, while not suitable for implants, is used in radiation shielding for medical imaging and therapy due to its density and protective qualities.

3. Automotive and Industrial Applications

| Material | Ideal Use | Considerations |

| Tungsten | High-wear parts (e.g., cutting tools, drill bits) | Excellent for high-wear applications but too heavy for most automotive uses. |

| Titanium | Exhaust systems, engine parts, suspension components | Ideal for lightweight, high-performance parts in automobiles. |

In the automotive and industrial sectors, titanium is widely used for lightweight, high-performance components like exhaust systems, engine parts, and suspension systems. Tungsten is more commonly found in cutting tools and drill bits where wear resistance and hardness are prioritized over weight.

4. Defense and Military Applications

| Material | Ideal Use | Considerations |

| Tungsten | Armor-piercing projectiles, radiation shielding | Perfect for defense applications where density and durability are paramount. |

| Titanium | Lightweight armor, vehicle parts, aircraft components | Used for parts that require a balance between weight reduction and strength. |

In defense applications, tungsten is preferred for armor-piercing projectiles and radiation shielding, where its density provides unmatched penetrative power and protection. Titanium, on the other hand, is used in lightweight armor, military vehicle parts, and aircraft components where both strength and weight savings are essential.

Cost Analysis of CNC Machining Tungsten vs Titanium

While both materials are costly, their CNC machining costs vary based on several factors, including tool wear, machining time, and material cost.

| Factor | Tungsten | Titanium |

| Material Cost | High (due to high density and rarity) | Medium to High (depending on grade) |

| Tool Wear | High (due to hardness) | Moderate (due to galling and heat) |

| Machining Time | Longer (requires slower cutting speeds) | Moderate (requires careful heat management) |

| Coolant Requirements | Moderate to High | High |

Cost Optimization Tips:

- For tungsten, reduce tool wear by using advanced carbide or diamond tools.

- For titanium, increase cooling efficiency to prevent warping and reduce rework costs.

- Use batch processing to minimize machine setup time and lower overall costs per part.

Case Studies: Successful Custom Part Machining with Tungsten and Titanium

Case Study 1: Aerospace Industry – Machining Tungsten for Heat Shields

An aerospace company needed heat shields made from tungsten for a rocket engine, where temperature resistance was critical. CNC technology allowed for precise machining, using diamond-tipped tools to handle tungsten’s hardness. The result was a custom part that withstood extreme temperatures without compromising structural integrity.

Case Study 2: Medical Devices – Machining Titanium for Implants

A medical device manufacturer needed biocompatible titanium implants for orthopedic use. CNC machining enabled precise cutting and shaping of titanium, ensuring each implant met strict medical standards for size, weight, and surface finish. The company successfully delivered custom implants with minimal post-machining work required.