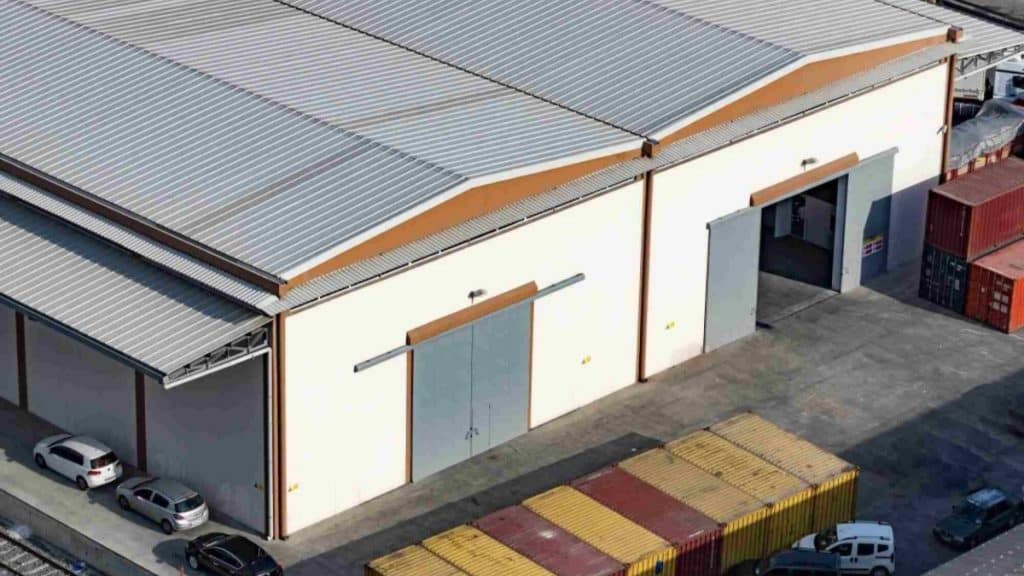

Industrial roofs are made for the purpose of factories, warehouses, and other similar large-scale facilities. Such must be strong, economic, and durable enough to be resistant to different environmental stresses during several years of operation. Types, materials, and maintenance of industrial roofs can help protect the business’s assets and reduce long-term costs. Here is a closer look at what goes into an industrial roofing solution and how to keep it in optimal condition.

1. Types of Industrial Roofs

There are mainly two types; flat roofs and low-slope roofs. Both have distinct properties that make them highly suited to certain industrial usage.

Flat Roofs: Flat roofs are utilized in most industrial applications since it adds space for machinery, such as HVAC systems, solar panels, and exhaust fans. Usually, they are quicker to erect and cheaper to install, repair, and maintain than pitched roofs.

Low Pitch Roofs: Even though almost flat, low pitch roofs are actually constructed with a slight incline so that water can drain out from them. This advantage can be helpful in areas of heavy precipitation or snowfall by preventing potential accumulation, which results in roof decay.

2. Industrial Roofing Materials

The industrial roofing materials used are tough, long-lasting, and resistant to harsh conditions. A few of the most common options available are:

Metal Roofing: Aluminum, steel, and copper are used to make metal roofs; they’re highly durable and can last over 50 years when properly maintained. These can be given a coat to prevent rust. The advantage of metal is that it reflects, thus keeping industrial facilities cool by reflecting the sun’s rays.

Built-Up Roofing (BUR): It is commonly used on flat industrial roofs. BUR is comprised of layers of tar, gravel, or asphalt. That makes it give excellent waterproofing and UV protection.

Modified Bitumen: It is similar to BUR because it is also applied in layers. It’s flexible, so it won’t crack because of extreme temperatures. Also, it is water-resistant and has an average life expectancy of around 20 years.

Thermoplastic Roofing (TPO and PVC): Thermoplastic roofing membranes, including TPO (Thermoplastic Polyolefin) and PVC (Polyvinyl Chloride), are lightweight, heat-reflective, and extremely resistant to chemicals and UV rays, making them ideal for facilities that are exposed to chemicals.

Benefits of Industrial Roofing Solutions

Industrial roofs are designed to provide a protective cover over valuable assets while improving energy efficiency. Some of the benefits include:

Durability: Industrial roofs are resistant to withstand heaviest of rains, intense heat, and other troubles like chemical exposure.

Cost Efficiency: In general, good quality industrial roofing materials require less maintenance, thereby reducing the long term costs.

Temperature Control: Reflective material used for TPO or Metal roofs stops extreme temperatures from building up inside the building which might reduce heating and cooling energy.

Water Resistance: A well-installed industrial roof is primarily water resistant and should leak very seldom to cause great damage to machinery, inventory, and structural members.

4. How to Maintain an Industrial Roof

Industrial roofs can last longer and are more effective when properly cared for. Here are the bare essentials:

Regular Inspections: Regular checks should be conducted bi-annually to identify any signs of damage or crack indications as well as pooling water.

Clear Obstacles: Sweep away leaves, branches, and other debris causing obstructions and water puddles on the roof.

Check Flashing and Seals: The flashing surrounding vents, skylights, and chimneys can crack with time. You should check and reseal them as needed to prevent leakage.

Respond to Leaks Immediately: When you notice any signs of leakage or water intrusion, you should respond immediately before the situation wreaks havoc on your structure and breeds mold.

Apply Protective Coatings: Apply protective coatings over the metal and modified bitumen roof every few years to give it strength as well as providing stronger resistance to the elements.

5. What is the Appropriate Industrial Roof for Your Business?

Of course, the right industrial roofing solution varies on several grounds, including the location of the facility, the climate, and the intended use for which the facility is constructed. For instance, an area characterized by a sunny and hot climate requires a reflective metal roof or TPO roof. On the other hand, a warehouse on a cold and rainy climatic area might prefer BUR or modified bitumen roofing that can resist the effects of water.

An industrial roof is a significant investment, and the right choice can save money and enhance the safety of the facility. Industrial roofs, with good materials and constant maintenance, provide considerable durable protection for large-scale businesses, securing operations and ensuring that valuable assets are well-protected.