Introduction

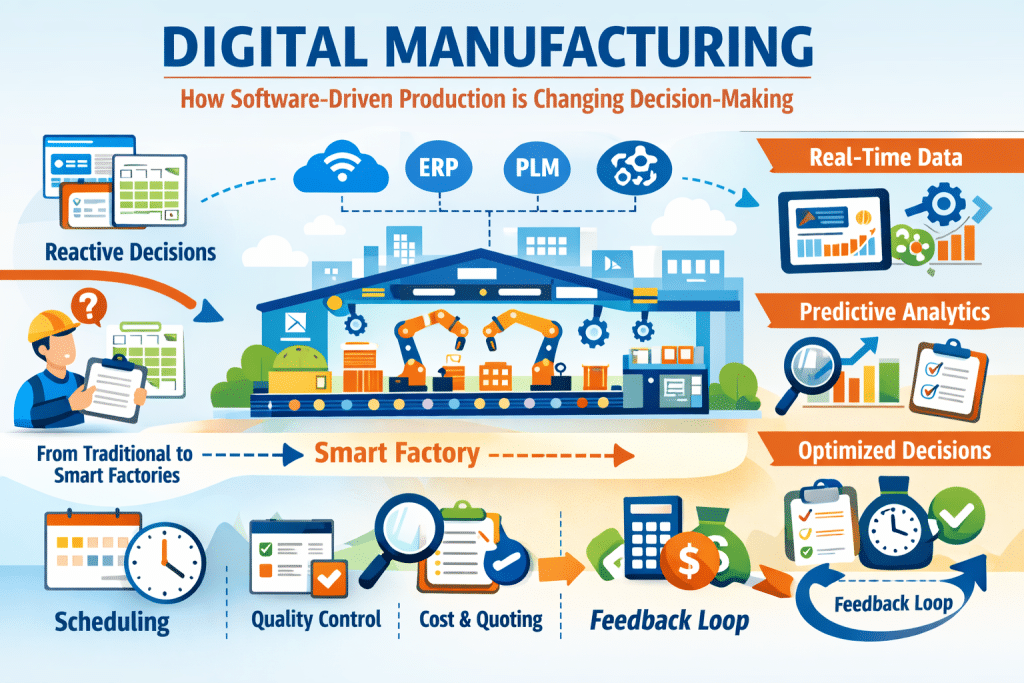

Digital manufacturing is a production approach that uses connected software, data, and automation to plan, run, and improve how products are made.

If that sounds abstract, picture a factory where decisions are not trapped in spreadsheets, tribal knowledge, or last week’s shift notes, but are continuously informed by live signals from machines, materials, and customers.

That shift matters because modern production is faster, more customized, and more fragile than it used to be, so the cost of a wrong decision compounds quickly.

In this guide, you will see how software-driven production changes everyday choices like scheduling, quoting, quality control, and capacity planning.

You will also learn what systems like MES, ERP, PLM, and simulation tools actually do, and where a digital thread and a digital twin fit in.

Along the way, we will cover benefits, limitations, cost ranges, common mistakes, and a practical implementation path that works in the real world.

What Is Digital Manufacturing and Why Does It Matter Today?

Digital manufacturing is the use of integrated software and connected data to make production decisions faster, more consistent, and more measurable.

In plain terms, digital manufacturing is a system that links design intent, shop-floor execution, and business planning so that each decision is based on a single source of truth.

Traditional manufacturing is a workflow in which decisions are often reactive, meaning people respond only after a problem arises.

Software-driven manufacturing is a workflow in which decisions are increasingly predictive, enabling teams to spot risks early, test scenarios, and choose the least-cost path before the line is disrupted.

That matters today because shorter lead times, volatile supply chains, and customer-level customization push factories to operate with tighter tolerances in time, cost, and quality.

Digital manufacturing also matters because it creates accountability for decisions.

A decision is an action that changes production outcomes, and software can connect that action to data, context, and results.

How Does Software-Driven Production Change Decision-Making?

Software-driven production changes decision-making by turning operational choices into measurable experiments that can be repeated, compared, and improved.

When the shop floor is connected, decisions stop being isolated events and start becoming part of a closed feedback loop.

A production schedule is a plan that assigns work to resources, and software can rebuild that plan in minutes when a constraint changes.

A quality issue is a deviation that increases scrap or rework, and software can trace that deviation back to a machine state, a material lot, or a process parameter.

Even a quote becomes smarter because quoting involves predicting time and cost, and predictions improve when trained on real production history.

This is where decision latency drops.

Decision latency is the time between noticing a problem and acting on it, and digital systems reduce that delay by surfacing signals early and routing them to the right people.

What Types of Software Power Digital Manufacturing?

Digital manufacturing software is a collection of connected systems that turn raw production data into actionable decisions.

In practice, these tools do not replace experienced engineers and operators; they amplify them by making the factory legible in real time.

A software stack is a set of integrated applications, and its goal is continuity from design to delivery, not a pile of dashboards that nobody trusts.

Below are the main software categories that typically power software-driven production decisions:

- Manufacturing Execution Systems that track and control work in real time

- Product Lifecycle Management platforms that manage product definitions and changes

- Enterprise Resource Planning systems that coordinate materials, cost, and planning

- Simulation and digital twin tools that test scenarios before changes hit the floor

- Industrial data platforms that collect and normalize machine data

Manufacturing Execution Systems

A manufacturing execution system is software that manages and monitors production activities as they happen on the shop floor.

It fits into digital manufacturing because it turns work orders into traceable operations, and traceability makes decisions defensible.

MES connects operators, machines, and instructions so that work happens in the correct order, at the right time, with the proper checks.

A routing is a defined sequence of operations, and MES enforces that routing, so quality controls are not skipped.

It also supports continuous improvement by consistently classifying downtime and defects, enabling teams to analyze and fix them.

Product Lifecycle Management Software

Product lifecycle management software controls how product data evolves from concept to design, release, manufacturing, and service.

It fits into digital manufacturing because decisions on the floor depend on constantly changing product definitions.

A revision is a controlled update to a part or assembly, and PLM ensures production always builds the correct version.

Engineering change decisions flow through PLM, keeping procurement, manufacturing, and quality aligned rather than working from conflicting data.

Enterprise Resource Planning Systems

Enterprise resource planning software coordinates purchasing, inventory, finance, and high-level production planning.

It fits within digital manufacturing because many production decisions are, in fact, business decisions about cost, timing, and risk.

A material requirement plan predicts what is needed and when, while cost rollups influence pricing and quoting.

ERP works best when it reflects shop-floor reality rather than forcing it to conform to static assumptions.

Simulation and Digital Twin Software

Simulation and digital twin software models production systems, enabling teams to test decisions before implementing them.

This matters because prediction reduces risk when downtime or quality failures are expensive.

A digital twin is a virtual model connected to real-world data that enables continuous validation.

Line balancing, capacity planning, and process changes can be evaluated without interrupting production.

This is also where additive manufacturing often enters the decision process.

In many digital workflows, additive manufacturing is evaluated alongside traditional methods, supported by production-grade equipment such as professional 3D printers from Raise3D.

A 3D printing process builds parts layer by layer, and software can decide when it offers speed, flexibility, or cost advantages over other methods.

What Is a Digital Thread in Manufacturing?

A digital thread is a connected flow of data that links product definition, process planning, execution, and performance feedback.

It fits into digital manufacturing because disconnected data leads to disconnected decisions.

Bills of materials, routings, inspection plans, and machine parameters remain synchronized through the thread.

A process parameter is a controllable variable, such as temperature or feed rate, and the thread links it to outcomes, such as scrap or cycle time.

Over time, the digital thread becomes organizational memory, capturing what worked, what failed, and why.

What Are the Main Benefits of Software-Driven Manufacturing Decisions?

Software-driven manufacturing delivers faster response, clearer visibility, lower waste, higher consistency, and greater scalability.

These advantages matter because they prevent minor issues from becoming systemic problems.

The main benefits include:

- Accelerating response by detecting issues early

- Improving visibility across machines, teams, and shifts

- Reducing waste by identifying root causes of scrap and rework

- Strengthening consistency through standardized workflows

- Scaling decision quality across products and facilities

What Are the Limitations and Challenges of Digital Manufacturing?

Digital manufacturing introduces integration complexity, data quality risks, upfront costs, and adoption challenges.

These issues arise because software changes how people work, not just the tools they use.

Common limitations include:

- Increasing complexity when integrating legacy systems

- Undermining trust when data lacks context or accuracy

- Raising initial investment requirements

- Slowing adoption when workflows feel burdensome

Digital Manufacturing vs Traditional Manufacturing Decision Models

Digital manufacturing differs from traditional models because decisions are driven by connected, real-time data rather than delayed reports or personal experience alone.

Traditional approaches work best in stable environments, while digital approaches excel when variability and speed increase.

Key differences appear in response time, accuracy, scalability, and predictability.

Factor | Traditional model | Digital model |

Data freshness | Delayed | Near real-time |

Root-cause analysis | Manual | Traceable |

Scenario testing | Limited | Simulation-based |

Standardization | Person-dependent | Workflow-driven |

Scalability | Difficult | Repeatable |

What Industries Benefit Most from Digital Manufacturing Decisions?

Digital manufacturing delivers substantial value in automotive, aerospace, medical, industrial, and educational environments.

These sectors manage complexity where decision quality directly affects cost and risk.

Industries that benefit most include:

- Automotive manufacturing

- Aerospace and defense

- Medical and healthcare production

- Industrial and commercial manufacturing

- Education and innovation labs exploring different 3D printing technologies

How Much Does Digital Manufacturing Software Cost?

Digital manufacturing software typically ranges from thousands of dollars per year for small deployments to hundreds of thousands for enterprise systems.

Total cost depends on scope, integration depth, and customization.

Key cost factors include:

- Deployment scale and number of users

- Integration with existing systems and machines

- Licensing and pricing models

- Custom workflows and reporting needs

How to Implement Digital Manufacturing for Better Decision-Making

Implementing digital manufacturing aligns systems, data, and people, enabling faster, more consistent decisions.

The process focuses on changing how decisions are made, not just installing software.

A practical implementation path includes:

- Defining which decisions need improvement

- Selecting software that fits real constraints

- Integrating machines, data, and workflows

- Training teams around decision-making tasks

- Reviewing outcomes and refining continuously

Clear visual communication also matters.

Many factories support real-time awareness through shop-floor displays, such as industrial LED screens from Dynamo LED Displays, to surface priorities, alerts, and performance metrics where work happens.

What Common Mistakes Do Companies Make When Going Digital?

The most common mistake is treating digital manufacturing as a technology project instead of a decision redesign.

Without clear decision goals, dashboards may look impressive but fail to change behavior.

Other mistakes include poor data governance, premature automation, and underestimating the importance of change management.

A simple rule helps guide success: a digital system creates value only when it improves a decision, and a decision creates value only when it improves a measurable outcome.

Conclusion

Digital manufacturing is a software-driven production model that improves decisions by connecting data, workflows, and feedback.

When systems like MES, ERP, PLM, and simulation tools work together, organizations gain speed, consistency, and resilience.

The real value is not automation for its own sake.

It empowers people with a better context, so choices are informed, repeatable, and scalable.

When implemented with clear intent, digital manufacturing becomes a lasting competitive advantage rather than a temporary upgrade.