Custom merch isn’t a fad—it’s an $11-billion market and growing. According to a 2024 Smithers report, global dye-sublimation revenue will reach $11 billion in 2025 and rise roughly eight percent per year through 2029. That momentum creates opportunity—and costly pitfalls—for new print shops. Industry guides note that understanding how dye sublimation actually works helps startups avoid many of those early pitfalls. In this 2026 checklist, we’ll show you exactly what to buy (and what to skip) so you can open a lean, future-proof sublimation studio.

Choose your sublimation printer

Your printer drives color accuracy, turnaround time, and profit. A purpose-built Sawgrass SG500 outputs an 8.5 × 14-inch sheet in about 45 seconds, with OEM ink costing roughly $1.25 per transfer. A converted Epson EcoTank costs about half as much up front, yet hands maintenance and color-profiling over to you. In the next two sections we compare both paths so you can pick the engine that balances cash flow, speed, and reliability.

Dedicated sublimation printers

If you value plug-and-play reliability, a dedicated desktop unit is the clear choice. Two models dominate small-business forums and trade shows:

Epson SureColor F170 – This 14-pound printer fits on a desk, feeds up to 150 sheets, and ships with 140 mL refillable ink bottles. Epson lists the MSRP at $499 and includes a one-year exchange warranty. Because the ink set is OEKO-TEX certified, you can market shirts as skin-safe without extra testing.

Sawgrass SG500 – Street prices average $650–$700 and include Sawgrass Print Manager, a growing ICC-profile library, and a three-year or 100,000-print warranty on units purchased after October 1, 2025. Tester site Printer Insights clocks output at up to 240 pages per hour (about 50 percent faster than the older SG400).

That premium buys time. You skip screwdriver conversions, color-profile hunting, and warranty gray areas. Unbox the printer, load the starter inks, and press a sellable transfer before lunch. If speed to first sale matters more than the lowest entry price, a dedicated model makes sense.

Next up: the converted-EcoTank route for owners who prefer sweat equity over sticker price.

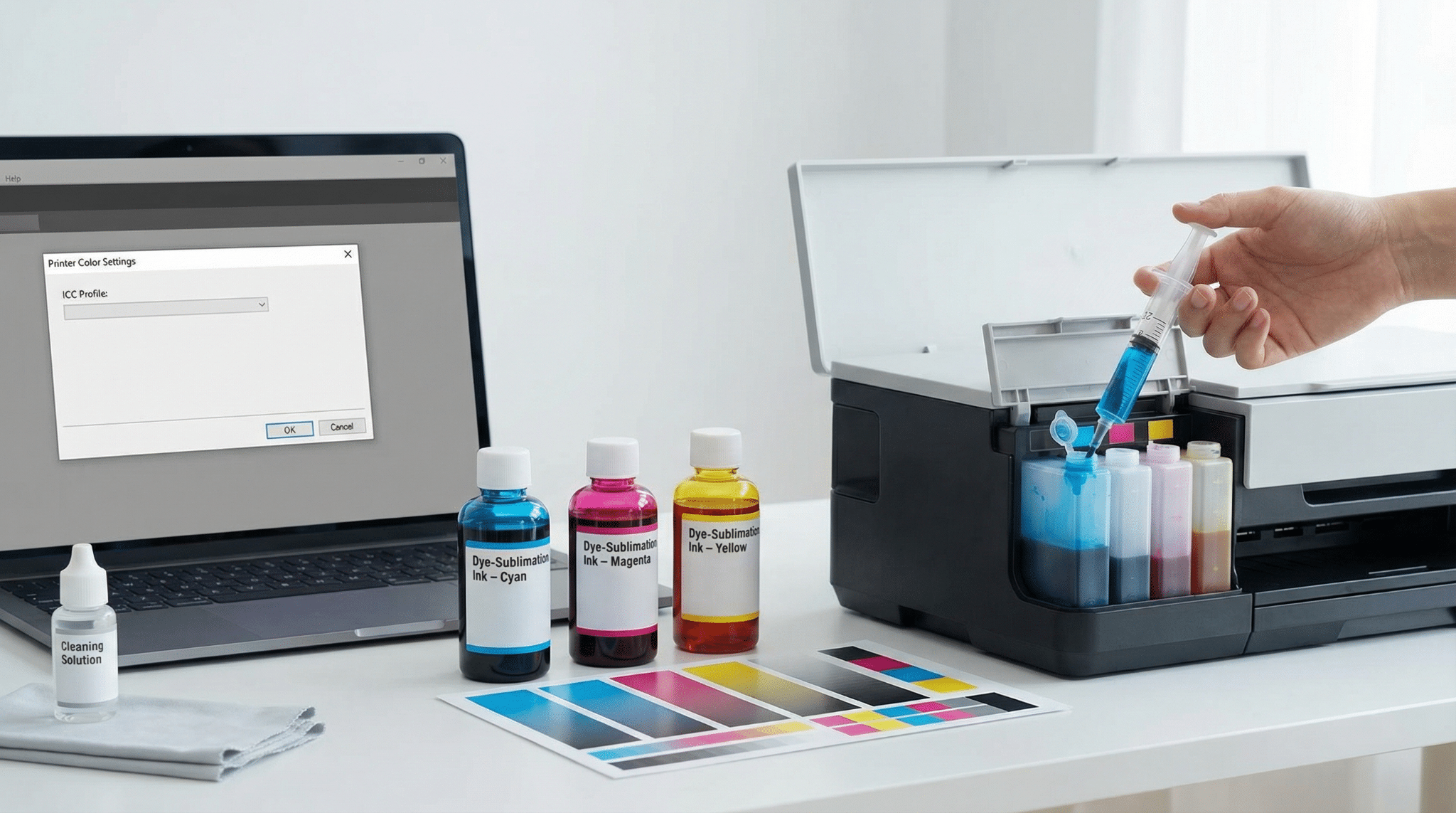

Converted EcoTank printers

Launching lean is possible. A new Epson EcoTank ET-2800 lists at $229.99 and often drops below $190 during sales. Skip the bundled pigment bottles, flush the tanks, and refill with a dye-sub set such as Hiipoo’s 4 × 100 mL kit for $16.99, enough for roughly 400 letter-size transfers at standard coverage. Your total outlay stays near $300, less than half the cost of a dedicated Sawgrass unit.

Know the trade-offs before you pour the first drop:

- Warranty risk. Epson states that damage caused by non-genuine ink “is not covered by Epson’s warranties.”

- DIY color management. Install the ICC profile from your ink vendor, print test charts, and tweak reds and blues until they match the screen. Plan one or two evenings for calibration.

- Extra maintenance. EcoTank heads dry out if idle. Run a nozzle check every few days and keep head-cleaning solution plus syringes on hand—cheap insurance against a clogged cyan channel during a rush.

Thousands of side-hustle shops still pick this route because it lets them prove demand first, then upgrade — much like how a small-batch studio might turn to a craft-supplier like Country Brook Crafts to source specialty blanks or finishing kits once the first runs sell out. Remember, you trade convenience for control, and control takes time along with a bit of tinkering.

Invest in a reliable heat press

Ink does not earn profit until it reaches about 400 °F (204 °C) at roughly 40 psi, the pressure-and-heat sweet spot Sawgrass lists for polyester sublimation. A quality press keeps that temperature steady across the platen, so finished prints survive the dishwasher, microwave, and laundry room. This section explains platen styles, size options, and real-world prices, yet the core rule remains the same: consistent, even heat bonds dye to polyester threads or a ceramic coating for years of use.

Flat heat presses for shirts, tiles, and more

For T-shirts, mouse pads, and photo panels, a flat press is the workhorse. Most shops start with a 15 × 15-inch clamshell such as the HPN CraftPro, advertised at $349.95. That platen handles kids’ tees up through adult XL fronts. If you sell blanket panels or 2XL jerseys, step up to a 16 × 20-inch bed; the larger press can weigh 15–20 pounds more and cost a few hundred dollars extra.

Press style shapes workflow, not print quality:

- Clamshell presses hinge like a laptop and save counter space.

- Swing-away units lift, then pivot, giving full access to the lower platen and more uniform pressure on thick substrates such as slate.

Whichever format you choose, confirm the machine reaches 400 °F (204 °C) and holds that heat within ±5 °F across the corners, a spec mid-tier models such as the HPN Signature Series ($529.95) publish on their product pages. Use an infrared thermometer to spot-check; a 20-degree cold zone can ghost half a design.

Budget cues: about $350 buys an entry-level clamshell suitable for a dozen shirts a day, while $700–$1,000 upgrades you to thicker platens, digital pressure readouts, and multi-year warranties (for example, HIX EVO Touch at $1,228.50). The premium feels steep, yet missing a holiday deadline while troubleshooting cold platens costs more.

Mug and tumbler presses, or the countertop oven workaround

Drinkware continues to lead sublimation sales, so even heat around a cylinder is essential.

Mug or tumbler press. A single-station press such as the HPN Signature Series sells for $189–$279 and cures an 11-ounce mug in 45–90 seconds at 365–385 °F. Most presses accept swap-in heaters for 15-ounce mugs and skinny 20-ounce tumblers, letting one chassis cover your catalog.

Convection-oven method. A $120 countertop oven plus silicone or shrink-wrap sleeves processes up to four mugs at once. Heat at 350–400 °F for about six minutes. This approach handles odd shapes such as camp mugs or enamel bowls, yet always dedicate the oven to sublimation and verify temperature with an oven thermometer to avoid dye fumes and cold spots.

Presses win on speed and one-handed operation; ovens win on shape freedom when space and budget are tight. Either route delivers factory-grade drinkware if you monitor temperature and pressure as carefully as you watch your coffee pot.

Stock up on true sublimation ink

Sublimation ink turns into gas and bonds with polyester; pigment ink does not. Choose bottles or cartridges that display “dye-sublimation” on the label.

- Sawgrass printers. Official SubliJet-UHD cartridges cost $77 for 31 mL (about $2.48 per mL) and include firmware-matched color tables.

- Epson F-series. OEM refill bottles list at $18–$20 for 140 mL (roughly $0.14 per mL) on Epson’s U.S. store.

- Converted EcoTanks. Third-party brands such as Hiipoo sell 600 mL (6 × 100 mL) for $49.99, or $0.08 per mL, on Amazon, but you must supply your own ICC profile.

Keep at least one spare set; nothing halts a Saturday rush like an empty magenta line. Unopened bottles remain stable for 12 months at room temperature, while opened bottles are best used within six months, according to most SDS sheets. Mark each cap with the date and rotate stock like milk.

For baby apparel or activewear, look for OEKO-TEX-certified inks such as Epson’s UltraChrome DS. The badge lets you market prints as skin-safe for schools and eco-focused shops, often worth the extra pennies per milliliter.

Choose high-release sublimation paper

Sublimation paper locks ink on the surface until about 400 °F (204 °C), then releases dye into the blank within a four- to six-second window. Independent tests by A-SUB show its 125 gsm “Quick-Dry” line transfers ≋94 percent of printed ink, a gain visible in deeper blues and reds.

Price is not the place to skimp. A 100-sheet letter pack costs $17–$20 on Amazon. Match sheet size to the printer: 8.5 × 11 inches for mug wraps and chest graphics, 11 × 17 or 13 × 19 for wide-format jobs. Trimming oversized sheets wastes money and risks curled edges that jam feed rollers.

Maintain paper under 50 percent RH. Store unopened packs in zipper bags with silica packets; pre-press fabric blanks for ten seconds in humid climates. When setting layout, print the first draft on plain copy paper—one cent there can spare a 25-cent sublimation sheet later.

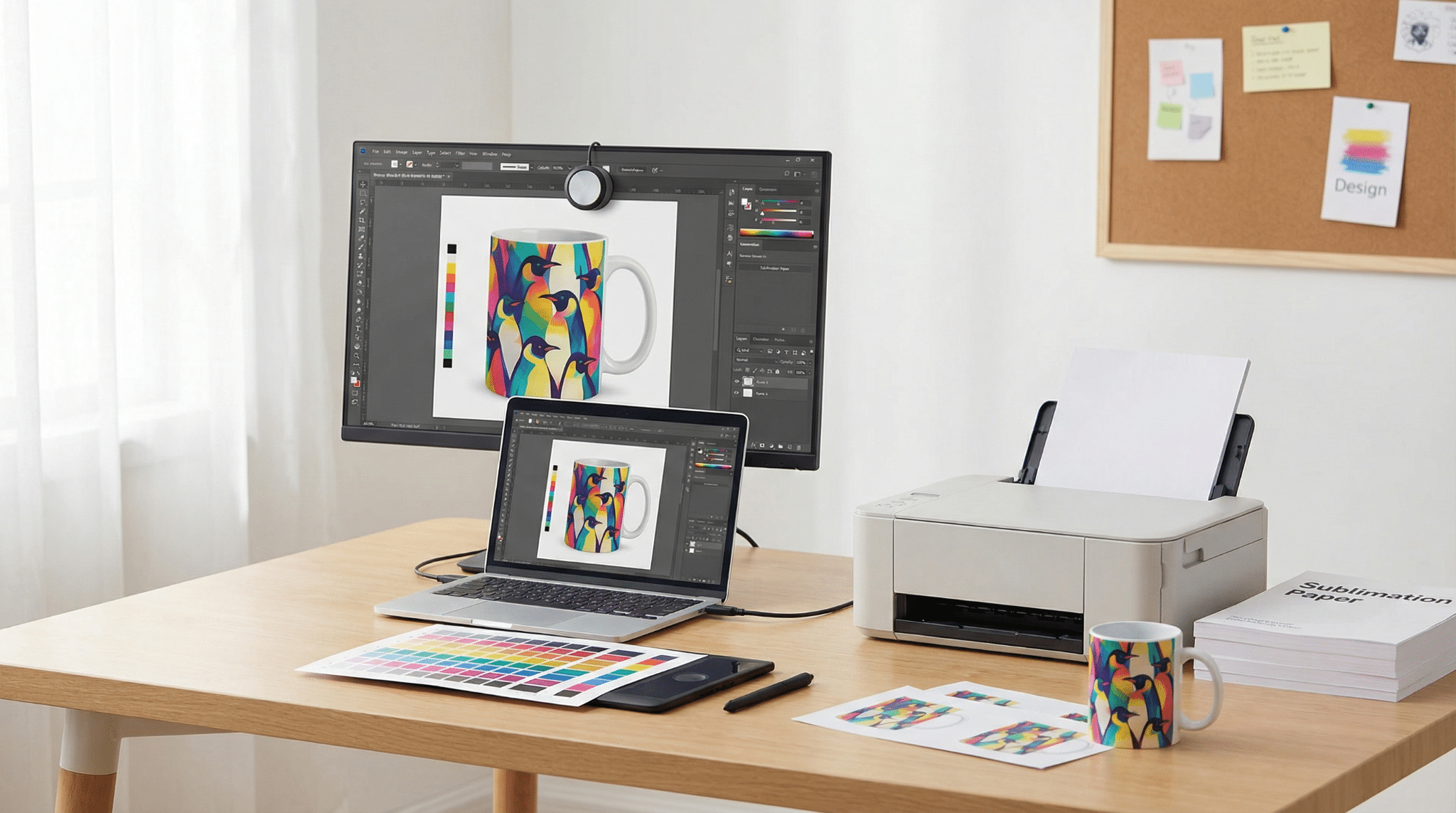

Set up your design workstation

Sublimation success depends on color accuracy, so treat artwork with the same care as ink.

Begin with a laptop or desktop that can open a 300 MB Photoshop file without lag; plan on at least 16 GB of RAM and a GPU-assisted display engine. Pair it with a monitor that covers ≥99 percent sRGB and calibrate monthly. Matching on-screen teal to printed teal prevents costly reprints.

Design software falls into three camps:

- Subscriptions. Adobe Photography Plan (Photoshop + Lightroom) costs $14.99 per month for new subscribers after January 15, 2025. Illustrator adds another $22.99 each month for vector work.

- One-time licenses. Affinity Designer or Affinity Photo run $69.99 each (pay once, update for years).

- Free starters. Inkscape (vector) and GIMP (bitmap) charge nothing but require manual color-profile setup.

Whichever tool you pick, install the ICC profile from your ink vendor before sending work to a client. A 10-second download avoids the “why is my red brown?” spiral.

Finally, respect intellectual property. Buy artwork from marketplaces such as Creative Fabrica or create originals. Customers value unique graphics; ensure they look great and meet legal standards.

Secure every print with heat-safe tape or spray

Even a millimeter of paper slip can leave a ghost image. Use consumables rated for at least 400 °F (204 °C) to hold transfers in place.

- Heat-resistant polyimide tape remains stable to 500 °F and peels clean from ceramic. Two strips across opposite edges secure mugs or metal panels. A 33-meter roll costs about $7 at most craft suppliers.

- Repositionable adhesive spray suits fabric, where tape may leave pressure marks. Hold the can 8–10 inches from the sheet, mist lightly, wait five seconds, then smooth onto polyester. After pressing, the paper lifts like a Post-it, leaving no residue or double shadow.

Rule of thumb: tape anything rigid or curved; spray anything that drapes. Follow this guideline, and every hoodie leaves the press without a blurry echo across the logo.

Shield your gear with protective paper

During pressing, dye vapor can drift beyond the design and stain the platen. A sheet of plain, uncoated 40-lb white butcher paper blocks that overspray for less than $0.02 per press when a 1,000-foot restaurant roll costs about $22 online.

Cut a sheet larger than the artwork, place it on top of the transfer, and add a second sheet under the garment to catch bleed-through. Discard the paper as soon as you see an outline; reusing stained sheets risks ghosting the next order. Store the roll in a dry bin, because paper that absorbs moisture wrinkles and creates pressure gaps.

Skip coated parchment and Teflon. Both trap moisture and can re-sublimate residual dye onto the next job. Fresh butcher paper for every press is inexpensive insurance against ruined platens and refund requests.

Protect your hands with heat-resistant gloves

Freshly pressed mugs and metal panels leave the heat zone at about 400 °F (204 °C), hot enough to cause third-degree burns in under a second. Wear gloves rated to ≥500 °F before lifting the press, peeling tape, or unloading an oven sleeve. A silicone-grip pair such as the Rockland BBQ glove costs $11–$14 and resists up to 932 °F, according to its ASTM test report.

Keep other micro-tools within reach: a $3 lint roller to remove stray fibers, a $20 infrared thermometer to find cold zones on the platen, and a surge-protected power strip for the printer. Safety gear may not be glamorous, yet it keeps production moving and skin intact.

Choose blanks that match demand and dye chemistry

Dye sublimation bonds to polyester (≥65 percent) or a polyester coating; cotton and raw ceramic cannot bond. Proven top sellers include:

- Drinkware. Wholesale 11-oz ceramic mugs cost about $1.20 each by the case of 36 at distributors such as JDS Industries. Keep 11-oz, 15-oz, and 20-oz skinny tumblers on hand, because drinkware still leads Etsy’s personalized-gift charts.

- Apparel. Stock core sizes of 100 percent polyester tees, plus “cotton-feel” ringspun poly shirts that earn a $3 retail premium.

- Fast add-ons. Coasters, keychains, and ornaments press in under 60 seconds and often retail at three times blank cost.

Order a sample bundle first, press test prints, and reject any lot with dull color or rough coating; this step prevents chargebacks. Buy cartons only after sales data confirms demand. Moving up to case quantities usually cuts unit cost 30–40 percent with most wholesalers. Rotate inventory so the oldest boxes ship first, because coatings can yellow after a summer in warehouse heat.

Quality blanks convert ink into revenue. Cheap or incompatible blanks convert it into refunds. Test, track, and let proven winners claim permanent space on your racks.

Fine-tune with quality-control extras

Small instruments catch problems before they touch your balance sheet.

- Infrared thermometer. A $19 temp gun checks platen corners in seconds; each spot should sit within ±5 °F of the set point.

- Hygrometer. Paper begins to ripple above 50 percent RH. A $12 digital meter plus a $40 tabletop dehumidifier keeps the room—and your transfers—stable.

- Power protection. A 600 VA UPS (about $65) gives the printer five to ten minutes to finish a job during an outage, while its surge filter shields the motherboard from voltage spikes.

Conclusion

These tools never print a shirt, yet each one saves time, ink, and blanks, guarding profit where it belongs: in your pocket.