Electrospinning technology has emerged as a pivotal innovation in various industries, offering a bridge between nanoscale engineering and practical applications. It is vastly transforming fields such as biomedical engineering, textiles, and more. In the heart of this technological evolution, Fluidnatek, the most advanced electrospinning equipment stands as a leader, redefining the capabilities of electrospinning in Spain. By leveraging advanced techniques and equipment, Fluidnatek is not only making significant waves in the industry but also paving the way for economic and environmental advancements in the country.

Introduction to Electrospinning Technology

At its core, electrospinning is a process that utilizes electrical forces to produce fine fibers from polymer solutions or melts. These fibers, often in the nanometer range, are used to create non-woven fabrics or membranes with unique properties. It’s also used in creating scaffolds for tissue engineering, drug delivery systems, and advanced filtration technologies.

The significance of electrospinning lies in its ability to fabricate materials with high surface area-to-volume ratios, making them ideal for applications requiring lightweight, extremely porous, yet durable materials.

The process of electrospinning involves applying a high voltage to a polymer-filled syringe, which ejects a thin jet of polymer from the needle’s tip. This jet elongates and thins into fibers upon contact with a grounded collector. As these fibers are collected, they form a mat that can be utilized for various applications. Electrospinning enables precise control over fiber properties such as diameter, alignment, and mechanical strength, directly influencing their industrial applications.

Fluidnatek’s Groundbreaking Innovations

What Sets Fluidnatek Apart?

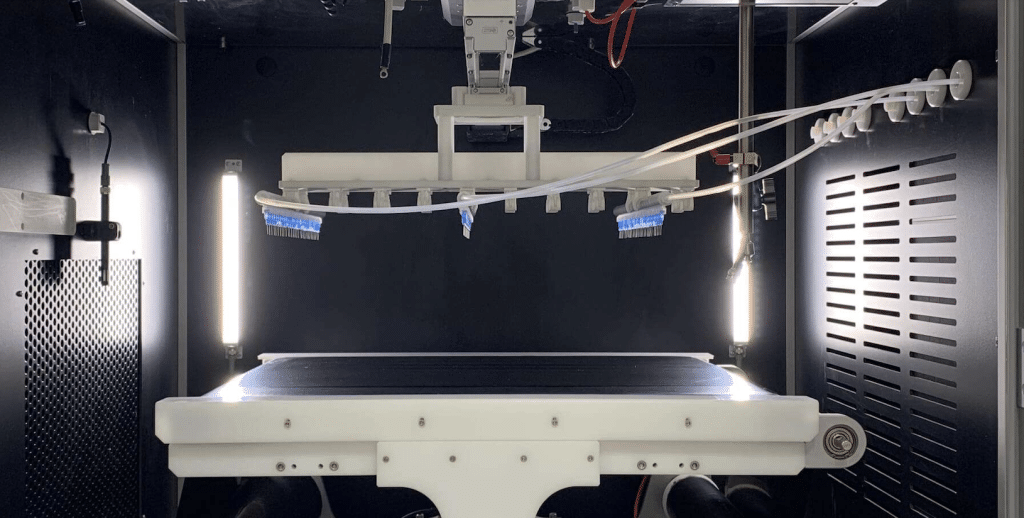

Fluidnatek, part of the Bioinicia Group, distinguishes itself in the electrospinning arena through its commitment to innovation and quality. Fluidnatek’s equipment is renowned for providing advanced functionalities that cater to both industrial and medical needs. Their investment in ensuring high precision and scalability is particularly noteworthy.

Why is precision vital in electrospinning?

Precision is crucial in electrospinning as it determines the uniformity and consistency of fiber production. Fluidnatek’s equipment ensures that every parameter—from voltage to collection distance—is meticulously controlled, significantly influencing the material’s behavior in end-use applications such as drug delivery systems and filtration membranes.

How does Fluidnatek achieve scalability?

Scalability is another key strength of Fluidnatek’s offerings. By integrating modular equipment designs and providing support for process scale-up from laboratory to industrial levels, Fluidnatek makes it possible for companies to produce at any scale necessary. Their commitment to seamless transition across different scales culminates in broad adoption across industries.

Impact on Spanish Industries

Transformative Applications in Biomedical and Textile Sectors

The impact of electrospinning on Spain’s industries is profound, with the biomedical and textile sectors witnessing significant transformations. In biomedical fields, electrospinning is fostering breakthroughs in tissue engineering, drug delivery systems, and wound healing technologies.

In addition to these two sectors, electrospinning also has a strong presence in Pharma, Energy, Filtration, Cosmetics…

Can electrospinning redefine biomedical applications in Spain?

Indeed, electrospinning is redefining biomedical applications in Spain by facilitating the development of biocompatible, porous, and highly functional materials. These materials can simulate the extracellular matrix, making them indispensable in regenerative medicine and organ repair. Fluidnatek’s technology enables precise control over fiber morphology, crucial for these sophisticated applications.

What advantages does electrospinning bring to textiles?

In textiles, the advantages of electrospinning are manifest in the production of high-performance fabrics. These fabrics, engineered at the nanoscale, provide superior filtration, thermal regulation, and moisture management—qualities sought after in industries ranging from sportswear to protective clothing. Fluidnatek’s equipment makes this cutting-edge production accessible to manufacturers in Spain, enhancing the country’s competitive edge in the textile market.

Catalyzing Economic and Environmental Growth

Beyond industrial applications, electrospinning as driven by Fluidnatek is promoting significant economic and environmental growth in Spain. This growth stems from the versatility and efficiency of electrospinning processes, meeting diverse market demands while aligning with global sustainability goals.

How can Fluidnatek influence Spain’s economic landscape?

Fluidnatek is significantly influencing Spain’s economic landscape by enabling industries to access advanced technologies that were once limited to global powerhouses. With improved access to scalable electrospinning technology, Spanish enterprises can innovate with confidence, likely leading to an increase in high-tech exports and a boost in national economic growth.

In what ways is electrospinning contributing to environmental solutions?

Electrospinning contributes to environmental solutions through its capability to produce lightweight, efficient filtration membranes and recyclable materials. These membranes have applications in areas like water purification and air filtration, critical for addressing environmental pollution. Fluidnatek’s environmental control units further assure that process consistency is maintained, optimizing resource use and minimizing waste.

Future Prospects for Electrospinning

The future for electrospinning looks promising, with ample opportunities for growth and innovation. As market demands continue to evolve, the technological advancements offered by Fluidnatek are set to keep pace with and support these changes.

Moreover, as countries embrace Industry 4.0, the integration of IoT and real-time data analysis within Fluidnatek’s equipment will foster smarter, more efficient manufacturing processes. The marriage of these technologies with the existing robust framework promises to drive further advancements and set new standards within industry.

In short, Fluidnatek’s commitment to innovative electrospinning solutions is enhancing the capabilities of industry. As companies and industries in implementing countries continue to adopt these technologies, the possibilities for economic and environmental progress will be truly limitless.