Temperature regulation in numerous industries is possible through efficient thermal management systems. They help release excess heat and maintain the functionality of devices, such as medical diagnostic equipment, chemical analyzers, drones, transportation systems, and refrigerators. Just read on as we discuss these incredible applications in more detail below.

Advancements in Thermal Management Applications

1. Medical Devices

The medical industry demands thermal control similar to that of other industries.. This electronic equipment performs well only if it stays cool enough to suit specific temperature limits. Several thermal management techniques are available to address overheating problems. However, medical device designers mostly use passive or active thermal control systems.

| Active thermal control | Passive thermal control |

| Blood analyzersCentrifuge machinesChromatography instrumentsAntibody testers | Magnetic resonance imaging Diagnostic machinesHeat sinks or pipesHeat spreaders |

2. Beauty

Ingredients used in beauty and cosmetics products are sensitive to temperature changes. Elevated temperatures can accelerate spoilage and reduce the quality of materials. If it is necessary to maintain a specific temperature for the formulas of cosmetics products, then a dependable thermal management system will be a suitable option to address this issue.

Moreover, other salon products that require efficient thermal control are:

- Cosmetic handheld lasers

- Thermostats

- Hair removal devices

- Radiofrequency devices for skin treatment methods

- Cryolipolysis machine (for frozen fat dissolving)

3. Laser Technologies

Industrial lasers have a wide range of uses, including drilling, cutting, welding, printing, and sewing. These processes generate a lot of heat, which can impact the precision and consistency of the system. On the other hand, controlled cooling allows lasers to operate for longer periods without compromising the quality.

Therefore, thermal management systems are vital for improving the efficiency of laser technologies, including:

- Projectors

- Stage lights

- Cutting machines

- Marking procedures

4. Telecom Infrastructure

As 5G communication technology advances, an increasing array of devices — such as base stations, RF towers, sensors, and other electronic equipment — face higher temperature conditions in their operation. A reliable thermal management system does this by transferring heat energy from the hot side to the cold side using the thermoelectric effect.

It keeps the devices at their typical operating temperature, enhancing their all-around efficiency.

5. New Electric Vehicles (EVs)

Thermal management in automobiles is essential to make sure passengers can travel comfortably. For components like temperature-controlled seats, car infotainment screens, temperature-regulated cup holders, in-car refrigerators, etc., effective temperature management is equally crucial. A flawed temperature control system may lead to component damage, performance degradation, shortened lifespan, and an unsatisfactory user experience.

6. Unmanned Aerial Vehicles (UAVs)

Heat buildup can cause damage to a drone’s batteries when charging. Using thermoelectric cooler assemblies in UAV charging cases can regulate temperature and prevent the battery from overheating during charging. This can not only maintain the battery’s health and lifespan but also ensure safe charging.

Innovations in Thermal Management Systems

Ancient civilians used alembic in distillation and alchemy procedures that worked on heat exchange thousands of years ago. Even today, heat dissipation is critical in electronic devices because too much heat can lead to severe drawbacks. Considerable research has been done over the years to improve heat dissipation technology and come up with better alternatives.

For instance, Japanese scientists recently summarized the evolution of heat sinks over five years. The study thoroughly reviews heat transfer concepts, including conduction, convection, irradiation, phase shift, and nanotechnology. Many such research studies are ongoing all across the globe.

Likewise, advanced cooling systems are also crucial for the modern industrial sector, industrial equipment, and other such machinery. Some of these mechanisms include:

- Spray cooling

- Evaporative air cooling

- Heat-pump based cooling

- Dry cooling

Recent advancements in heat transfer technologies have significantly improved thermal management systems. In addition to traditional methods like conduction, convection, and radiation, phase change materials (PCMs) and nanotechnology have greatly enhanced efficiency.

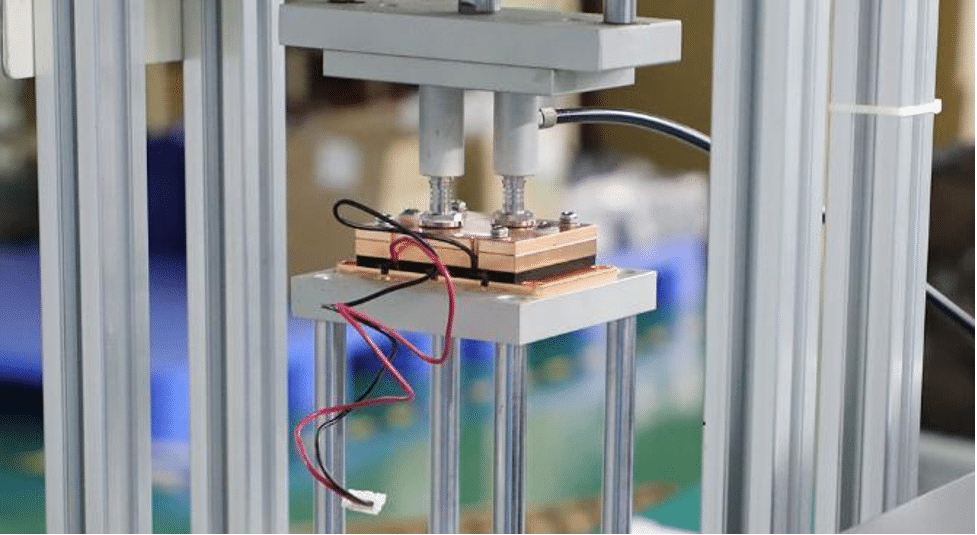

Peltier cooling technology, which utilizes the thermoelectric effect to transfer heat via electric current, offers benefits such as no moving parts, low noise, and precise temperature control. This technology is particularly effective for applications requiring exact temperature management. Building on these advancements, our products, including air-cooled modules and liquid-cooled modules, provide tailored solutions for diverse cooling needs.

Why Choose Huajing as Your Only Thermal Management Solution?

Huajing stands out as a premier choice for thermal management solutions, offering a host of state-of-the-art benefits tailored to meet the diverse needs of various industries. Here are some key reasons to choose Huajing:

Comprehensive Product Range

Our product offerings include air-cooled module, liquid-cooled modules, and more, designed to provide efficient and reliable temperature control across a range of applications. Whether it’s for medical devices, beauty equipment, laser technologies, telecom infrastructure, electric vehicles, or unmanned aerial vehicles, Huajing has the right solution to ensure optimal performance and longevity.

Customized Solutions

We understand that every industry has unique thermal management needs. That’s why Huajing offers custom-made solutions, designed to address the specific challenges faced by our clients. Our tailored approach ensures that you receive a solution that perfectly fits your requirements, providing superior performance and cost-effectiveness.

Conclusion

Thermal management systems play a pivotal role across diverse industries, ensuring optimal performance and durability of equipment. From medical devices to electric vehicles and drones, maintaining precise temperatures is crucial. Ongoing innovations, such as nanotechnology and advanced cooling methods, continue to enhance these systems. Huajing stands out as a premier solution provider, offering tailored, efficient, and precise thermal management across various sectors. For more queries, please contact Huajing. A team of qualified experts will get back to you in less than a day.

Reference

[1] Recent Development of Heat Sink and Related Design Methods. Available at: https://www.mdpi.com/1996-1073/16/20/7133 (Accessed: January 10, 2024)